-

-

November 20, 2024 at 2:38 am

ll00023

SubscriberI am running a 2-d RANS case for non-premixed oxy-coal combustion in an elevated pressure environment.

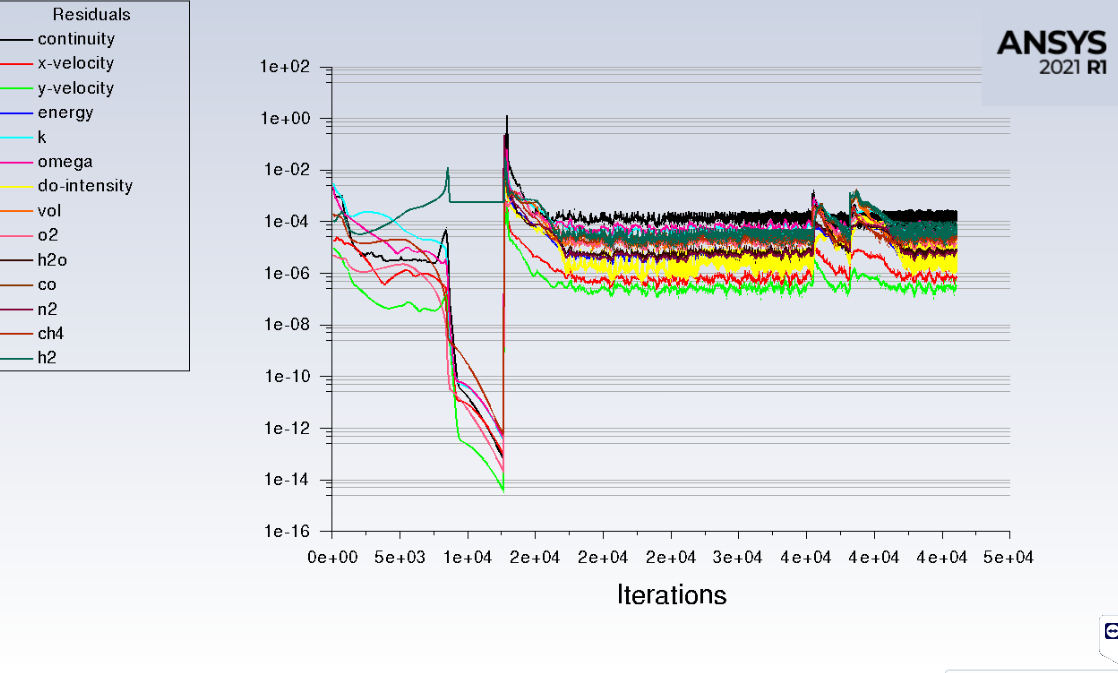

the models used: kw-sst for turbulence, species transport with finite rate/eddy dissipation model for combustion, DPM model for particle, DO model for radiation.

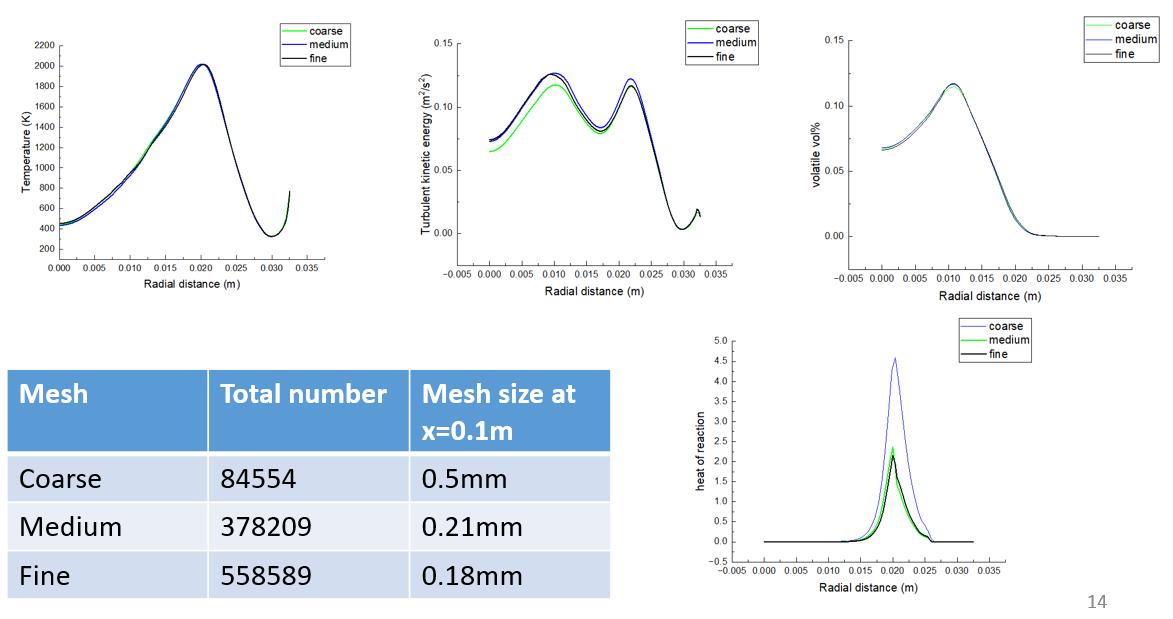

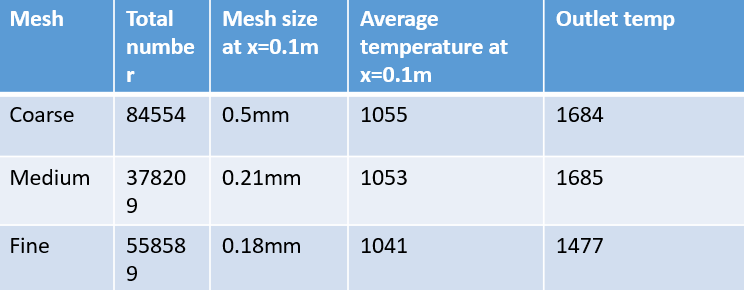

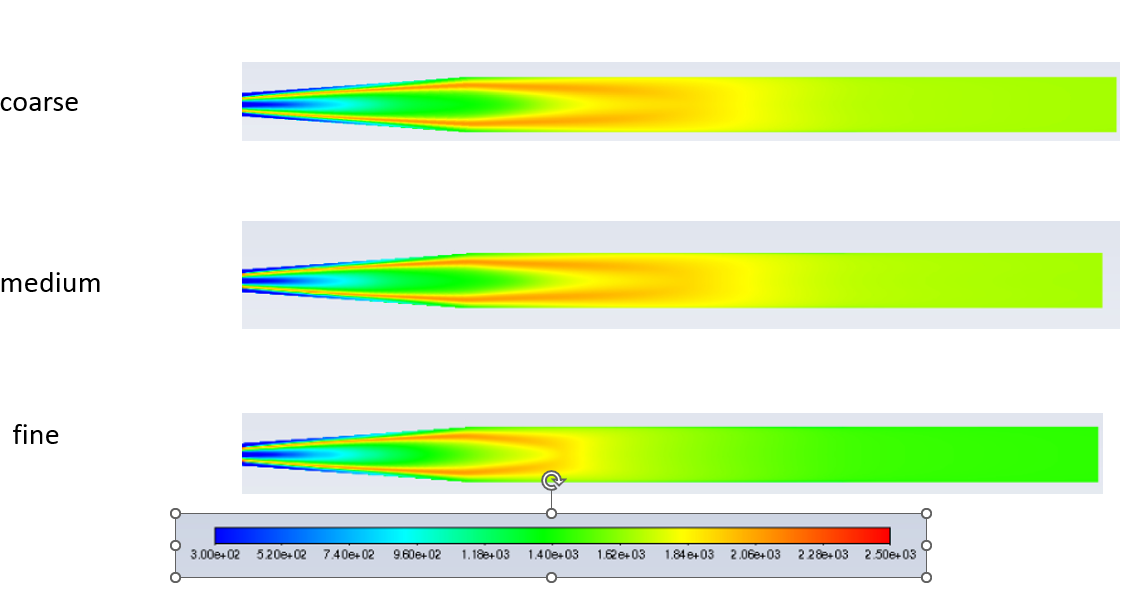

3 meshes are generated in ICEM; quality check is good.

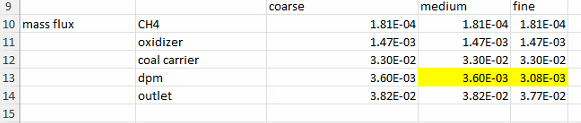

the temperature, TKE, volatile concentration are quite close for these mesh. but heat of reaction profile shows big differences between coarse and medium/fine mesh.

is this caused by finite rate/eddy dissipation model, because this model use a piece-wise function to get the reaction rate?

Thank you.

-

November 20, 2024 at 11:47 am

Rob

Forum ModeratorIt may also be the coarse mesh not being sufficiently resolved in the flame region. I'm assuming the particles are much smaller than the cells in all cases as you're using DPM.

-

November 20, 2024 at 2:34 pm

ll00023

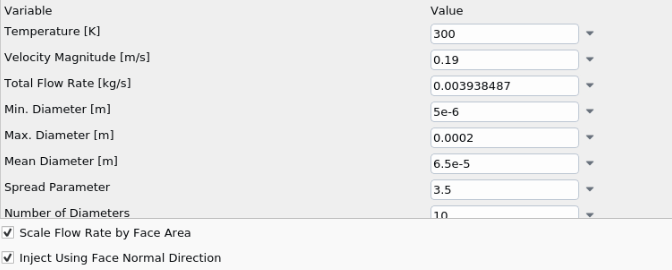

SubscriberParticle average size is 65 micron. they are smaller than cell size.

I think you are right that coarse mesh is not being sufficient to resolve the flame region of the non-premixed flame at the flame front.

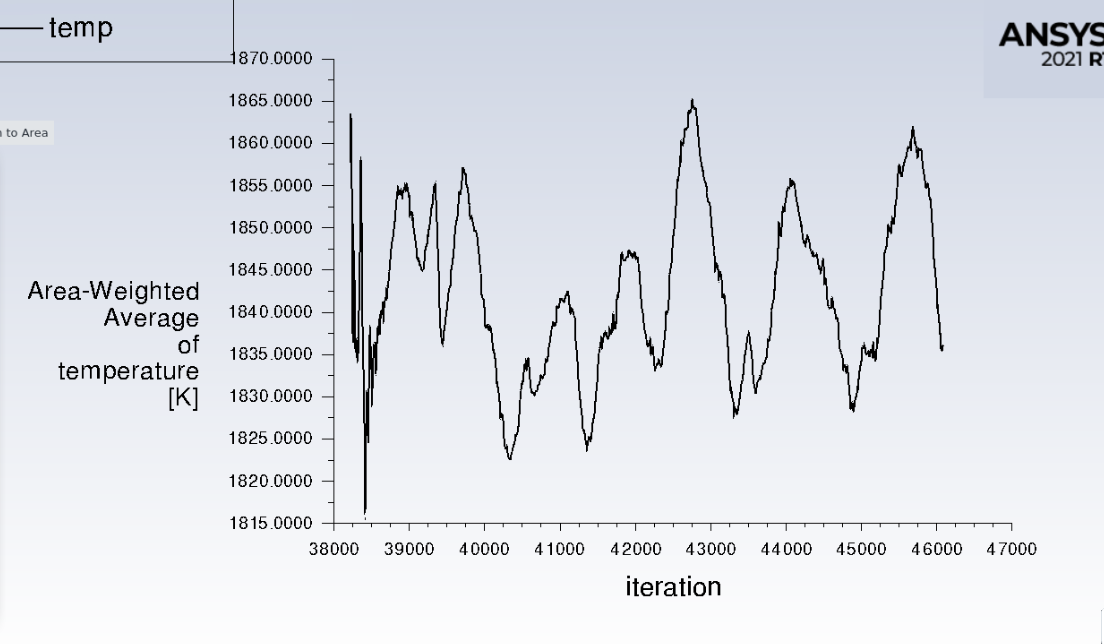

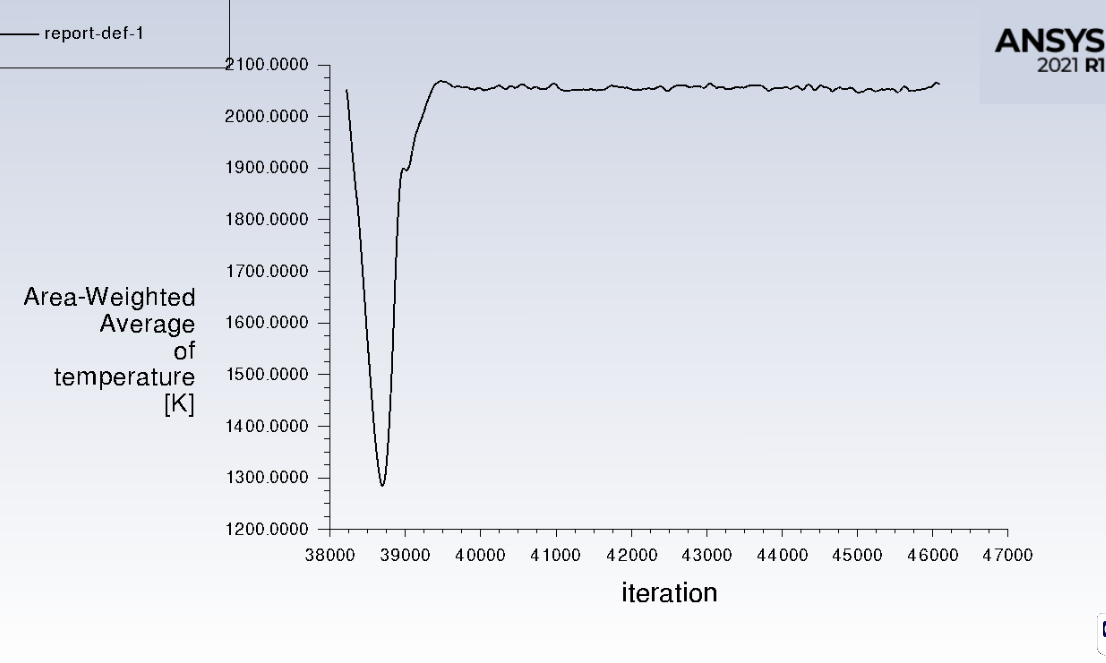

the coarse mesh can capture the location of flame front, the features of turbulent flow. so now it is a cost-benefit analysis. as you can see from the table, upstream (x=0.1) temperature is similar but downstream (outlet) shows differences. I assume the downstream part does not converge well for the fine mesh.

What's your suggestion to deal with this situation?

Thank you for your reply, Rob. I appreciate it.

-

November 20, 2024 at 2:46 pm

Rob

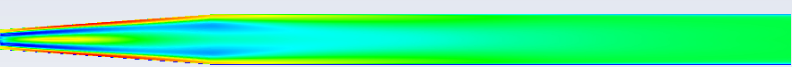

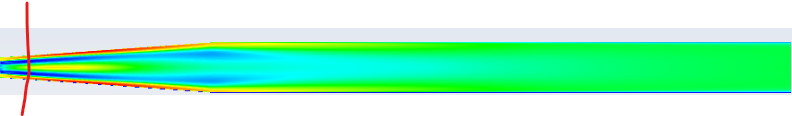

Forum ModeratorI'd look at contours etc to understand the flow field. A single point/surface result isn't always overly diagnostic. Why assume something when you can look at the results?

-

November 20, 2024 at 3:27 pm

ll00023

SubscriberThe flow field looks reasonable and consistent. but I can't post it here.

the issue here is: the inconsistence of heat of reaction at the flame front seems shaking the whole simulation's credibility.

I assume the simulation capture the main feature of the flow and combustion. but if the goal of the simulation is to find the flame dynamics, then the mesh needs to be much finer than the current case.

-

November 20, 2024 at 3:35 pm

Rob

Forum ModeratorAnd I can't comment on what I can't see. As an aside, if you're using Academic licences you do need to be publishing at some point.

-

November 20, 2024 at 3:48 pm

-

November 20, 2024 at 3:51 pm

-

November 20, 2024 at 4:34 pm

Rob

Forum ModeratorI checked with a colleague. As you're monitoring at a position, can you check the change in mesh hasn't move the reaction zone slightly? Also check point monitors, residuals and fluxes.

-

November 20, 2024 at 5:12 pm

-

November 20, 2024 at 5:50 pm

-

November 21, 2024 at 11:59 am

Rob

Forum ModeratorOdd, what did you set for the injection?

-

November 21, 2024 at 1:16 pm

-

November 21, 2024 at 3:13 pm

Rob

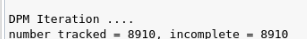

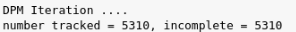

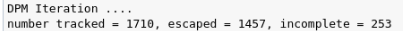

Forum ModeratorIncomplete tracks won't help. That's mass that is just "lost" in the calculation.

-

November 21, 2024 at 3:20 pm

-

November 21, 2024 at 3:31 pm

-

November 21, 2024 at 3:45 pm

Rob

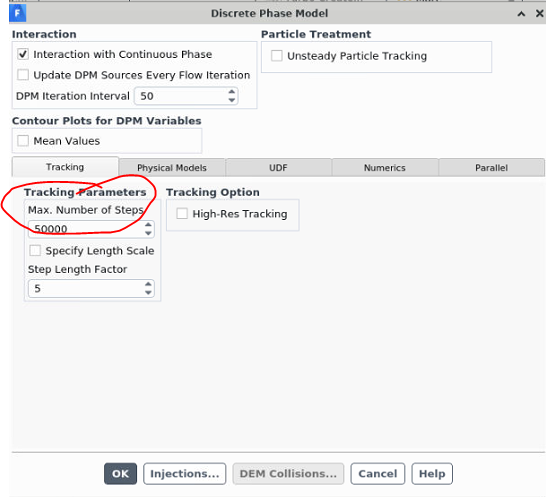

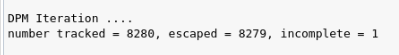

Forum ModeratorThat's better. The Max Steps meaning is covered in the various manuals: 5000 can be low for some cases.

Incomplete means a particle runs out of integration steps and is "vanished" from the model. All mass & energy in the track is also removed from the domain. A few percent missing is fine, but with combustion you're also losing the fuel....

-

November 26, 2024 at 2:32 am

ll00023

Subscriberit seems different meshes have different max. number of steps. if the number is too large, the simulation result is abnormal, based on the temperature profile.

-

November 26, 2024 at 2:15 pm

Rob

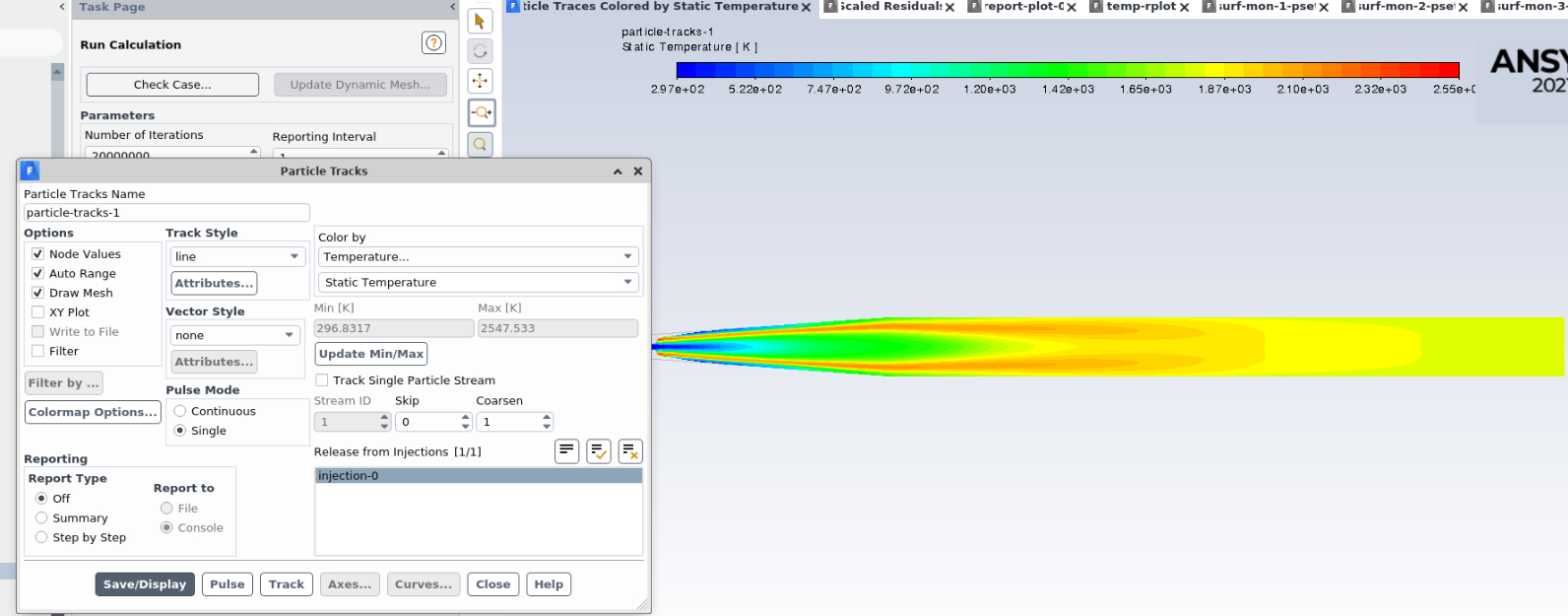

Forum ModeratorThat could mean you've got particles stuck somewhere. Have you plotted particle tracks along with flow field and temperature?

-

November 26, 2024 at 4:38 pm

-

November 26, 2024 at 4:42 pm

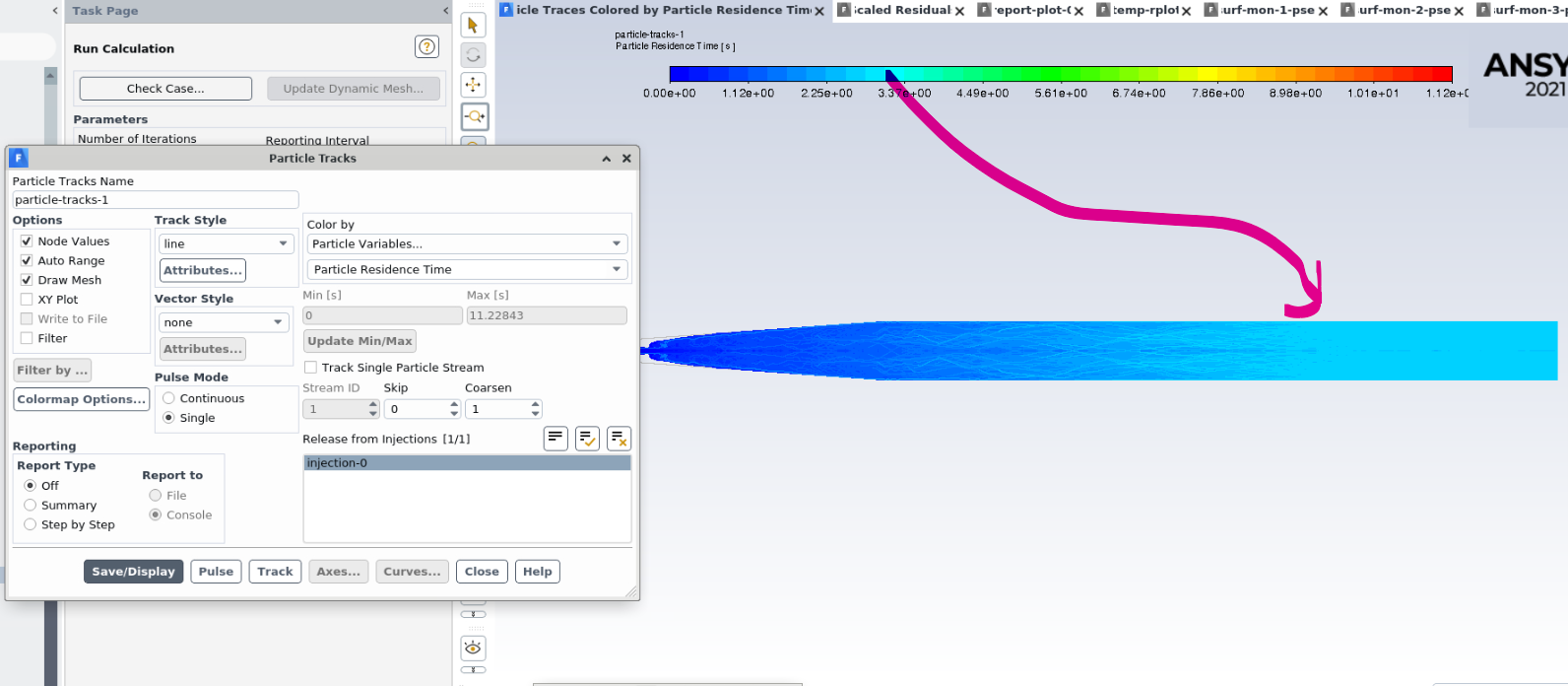

Rob

Forum ModeratorLooks sensible. And the particle ages?

-

November 26, 2024 at 4:53 pm

-

- You must be logged in to reply to this topic.

-

2778

-

965

-

841

-

599

-

591

© 2025 Copyright ANSYS, Inc. All rights reserved.