-

-

October 28, 2017 at 12:41 am

peteroznewman

SubscriberOne of the accessories carried around daily is a water-filled plastic tube. Since it is carried around, surviving a 15 inch (38 cm) drop was one of the requirements it had to pass. A physical test demonstrated that the initial design failed the drop test.

I built a transient dynamics model of the initial design to show that the part was predicted to fail, which was some evidence that the model was valid. The water was modeled as an orthotropic solid.

Plotting the peak stress showed that the maximum stress in the model exceeded the ultimate strength of the material.

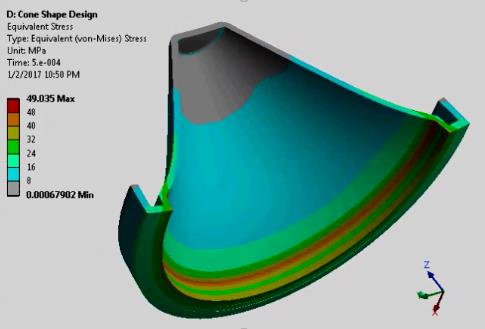

I went through many design iterations to find a few designs that were predicted to survive the drop test such as this one, which reached a peak stress of 49 MPa at 0.5 ms after impact.

Attached is a zip file containing a Microsoft Powerpoint 2013 file that has a summary report including the properties of water and some videos of the simulations.

[UPDATE: February 2020. I just learned about Hydrostatic elements and a SimuTech Group tutorial on how to use them.]

-

October 31, 2021 at 10:32 pm

nds88

SubscriberHi Peter,

I reviewed your slides that you attached and I am not sure that I agree with your assumptions on the container water as an orthotropic solid. Your slides show that you assigned the same properties in every direction at 2200 MPa Tensile modulus, 0.49 Poissons ratio, and 2.2 Pa for your Shear Modulus. Doesn't that essentially mean you created an isotropic solid? Also, Your reference ( http://hyperphysics.phy-astr.gsu.edu/hbase/permot3.html#c1) for this assumption is sparse in content, it mentions a bulk modulus for water to be 2200 MPa, but it looks like you used that definition for your tensile modulus. Even if you were going to assume the isotropic relationship from Bulk to Tensile modulus, that doesn't seem to add up. Other than proving that you created a stress above Ultimate Tensile Strength of your Lexan, how can you consider this validated? As for Lexan, isn't that a viscoelastic? Would a fluid structural interaction be an alternative to the orthotropic water assumption? Thanks.

-

October 31, 2021 at 11:36 pm

peteroznewman

Subscribernds88 Thanks for your interest.

Yes, the material is isotropic, but I could not use the Linear Elastic Isotropic material model in ANSYS because it enforces a defined relationship between Tensile Modulus, Poisson's Ratio and Shear Modulus. Any two inputs can be given and the other is calculated. Since I set the Tensile Modulus equal to the Bulk Modulus, and I want a high Poisson's Ratio to create an almost incompressible material, that results in a high Shear Modulus when using the Isotropic material model. Water has a zero shear modulus, so I used an Orthotropic material model which allows me to independently define the three values and use a Shear Modulus that is 10^9 times smaller than the Tensile Modulus.

Validation was achieved in two ways. One: a simulation result predicted failure and an experimental result demonstrated failure. Two: a simulation result predicted no failure and an experimental result demonstrated no failure.

While Lexan may behave as a viscoelastic material on the time scale of minutes, on the time scale of milliseconds, there is no time for any significant viscoelastic strain to develop, it is all elastic until fracture.

The water was in the model to add mass and apply pressure to the container on impact. No motion of the water was required for the pressure wave to travel through the whole structure and stress the container. Having the water as a solid material simplified the simulation. A more complex simulation could have been built with a fluid-structure interaction, but I did not have a license for Fluids so I had to make do with a Structural license. A couple of years later, while answering a question on this site, I looked into a better way to simulate a fluid filled container. See this discussion: /forum/discussion/13075/fluid-contained-within-a-structural-volume

-

November 4, 2021 at 11:21 pm

nds88

SubscriberThanks Peter, understood!

-

- The topic ‘Drop Test of a Water-Filled Tube’ is closed to new replies.

-

4678

-

1565

-

1386

-

1242

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.