-

-

October 28, 2024 at 6:19 am

menastap

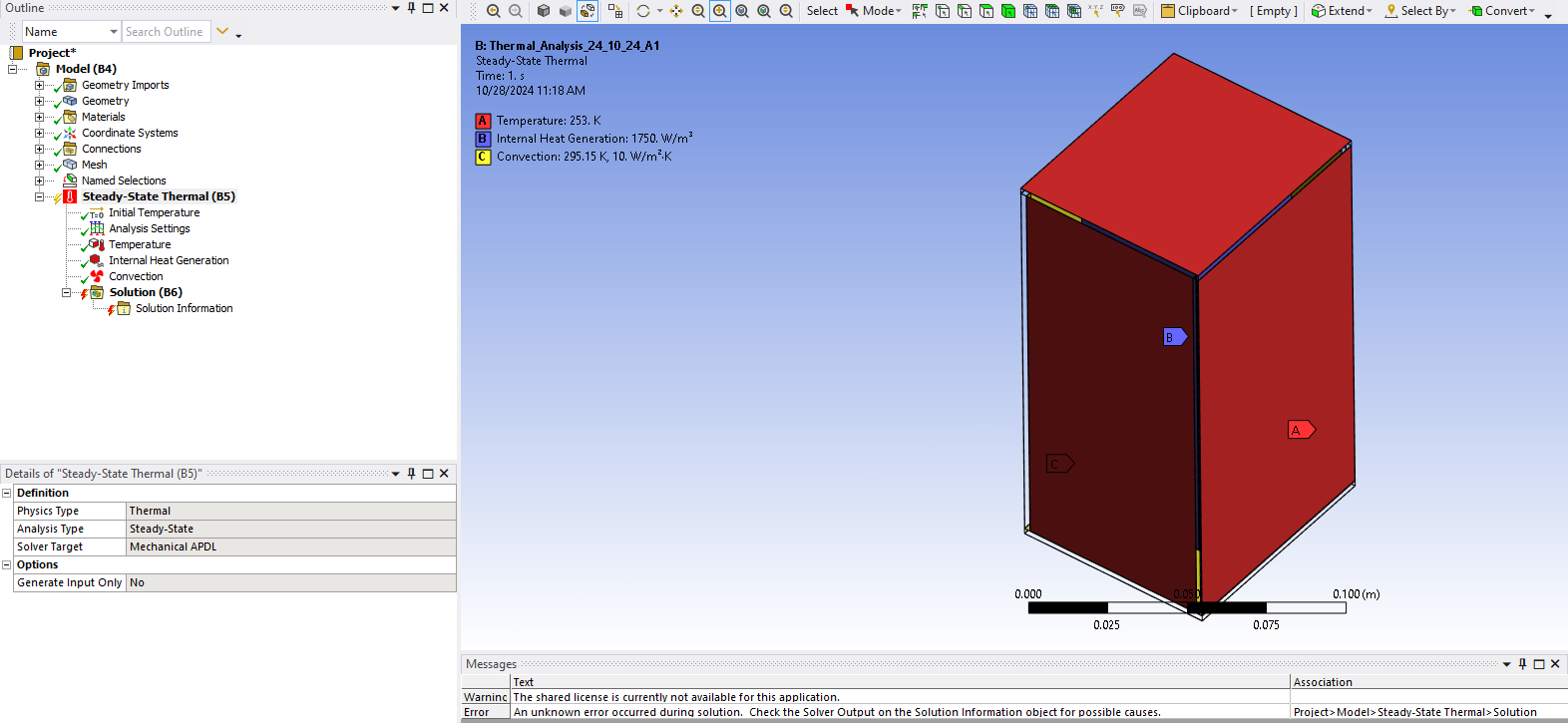

SubscriberHi , hope all you are doing well. I have to find the temperature inside the cabinet while elextronics installed dissipate 1750 watt heat. As per my understanding, i can do this through steady thermal analysis . I have tried but solution can't run beacuse of memory issues. Please guide me , how do i make it possible with limited memory source. Below figure depicts the defined geometry

-

October 29, 2024 at 2:38 pm

Rob

Forum ModeratorYou'll be better off asking in the Mechanical channel. For CFD I'd make a few assumptions regarding the casing and then model the buoyant flow.

-

October 29, 2024 at 4:49 pm

Pedram Samadian

Ansys EmployeeHi,

Thanks for contacting us. When you encounter memory issues in LS-DYNA, especially with limited memory resources, there are several ways to optimize your simulation for more efficient memory use, which are outlined below:

– Reduce the Element Count

- Mesh Optimization: Use a coarser mesh in regions where high accuracy is not crucial and apply a finer mesh only in areas of interest (e.g., stress concentration zones). This reduces the memory needed to store and compute element data.

– Use a Single Precision Version of LS-DYNA

- Single Precision Solver: Run the solver in single precision if double precision isn’t required for your application. Single precision uses half the memory of double precision and can still yield good results, especially for non-high-accuracy simulations.

– Optimize Contact Definitions

- Simplify Contact Types: Use simpler contact definitions where possible. For instance, *CONTACT_AUTOMATIC_SINGLE_SURFACE consumes more memory than *CONTACT_AUTOMATIC_SURFACE_TO_SURFACE. Only use the former if absolutely necessary.

– Reduce Output Frequency

- Database Output: Lower the output frequency of results files like D3PLOT and GLSTAT, which consume a lot of memory and disk space. For example, change from every 0.1 ms to every 1 ms if appropriate.

- Selective Output: Disable unnecessary outputs, or only save variables critical to the analysis. For example, avoid saving stress and strain at every time step if they are not essential.

– Run on Fewer Processors

- Processor Adjustment: Running on too many processors with limited memory can lead to memory fragmentation and increased demands. Try reducing the number of processors to optimize memory use, especially on machines with limited cores and RAM.

– Simplify Element Types

- Switch to Simpler Elements: If your model allows, use simpler elements (e.g., reduce higher-order elements to linear elements) to cut down on memory use.

If you continue to experience difficulties, it may be beneficial to consult the LS-DYNA user documentation or reach out to Ansys support for more targeted advice on managing memory usage for your specific simulation scenario.

Thanks,

Pedram

-

October 30, 2024 at 8:31 am

deepak.deepak

Ansys EmployeeHi, Can you please check with the difficult mesh setting? Thanks, Deepak -

October 31, 2024 at 4:21 am

menastap

SubscriberThanks alot to all. I will try, hopefully issue will be resolved

-

- You must be logged in to reply to this topic.

- air flow in and out of computer case

- Varying Bond model parameters to mimic soil particle cohesion/stiction

- Eroded Mass due to Erosion of Soil Particles by Fluids

- I am doing a corona simulation. But particles are not spreading.

- Issue to compile a UDF in ANSYS Fluent

- Guidance needed for Conjugate Heat Transfer Analysis for a 3s3p Li-ion Battery

- JACOBI Convergence Issue in ANSYS AQWA

- affinity not set

- Resuming SAG Mill Simulation with New Particle Batch in Rocky

- Continuing SAG Mill Simulation with New Particle Batch in Rocky

-

4492

-

1494

-

1376

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.