-

-

April 27, 2024 at 6:51 pm

Ken Ng

SubscriberHi,

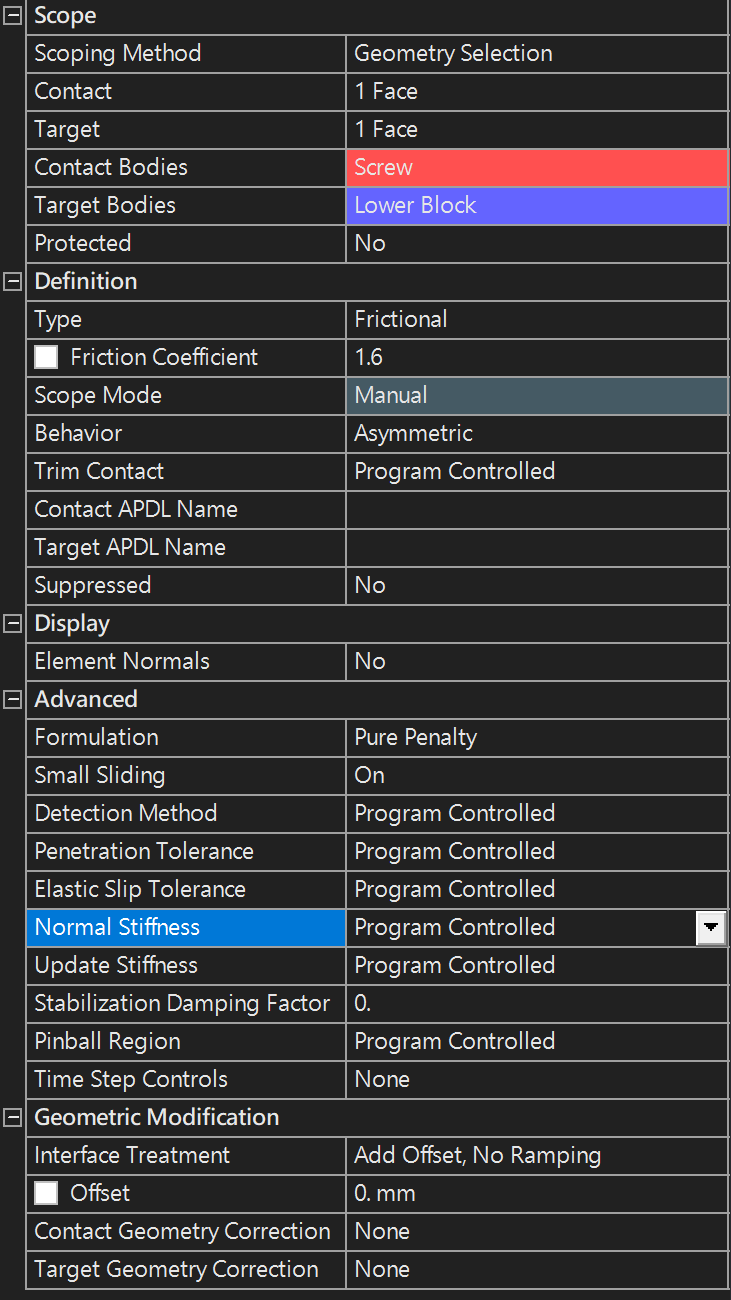

I am new to Ansys and I am trying to create the normal force for the friction of a pull-out test through the penalty method. So I read the guide and tried to mess around in Mechanical, and I found there are 2 ways to change it to the penalty method, which are the command and the parameter in detail of the contacts. I am not sure which one is the correct way to do the penalty method, so I wonder what are their differences and which is the right one. (actually, I think I failed to use both methods as they all give the same result as "Program Controlled", but I am not sure which parts go wrong

Method 1: APDL command in contactset ,cid, 174

KEYOPT,CONT,2, 1

KEYOPT,CONT,3, 1https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v241/en/ans_elem/Hlp_E_CONTA174.html

Method 2: Change the parameter in detail of the contacts

et ,cid, 174 -

April 29, 2024 at 11:39 am

Ashish Khemka

Forum ModeratorHi,

Why not use the deflaut 'Program Controlled' which is Augmented Lagrange forumulation. For comparison of different algorithms please refer to the links below:

PowerPoint Presentation (ansys.com)

Understanding Basics of Contact - Lesson 2 - ANSYS Innovation Courses

Regards,

Ashish Khemka

-

April 29, 2024 at 11:45 am

Ken Ng

SubscriberHi Ashish,

Thank you for answering, I'll try it and see their differences. And I wonder what is the difference between change the parameters in detail and using the commands code?

Regards,

Ken

-

-

- The topic ‘The enable of penalty method’ is closed to new replies.

-

4703

-

1565

-

1386

-

1242

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.