TAGGED: 2d-dpm, dpm, dpm-concentration, dpm-injection, dpm-model

-

-

April 25, 2022 at 10:09 am

Lorenzo_P

SubscriberHi,

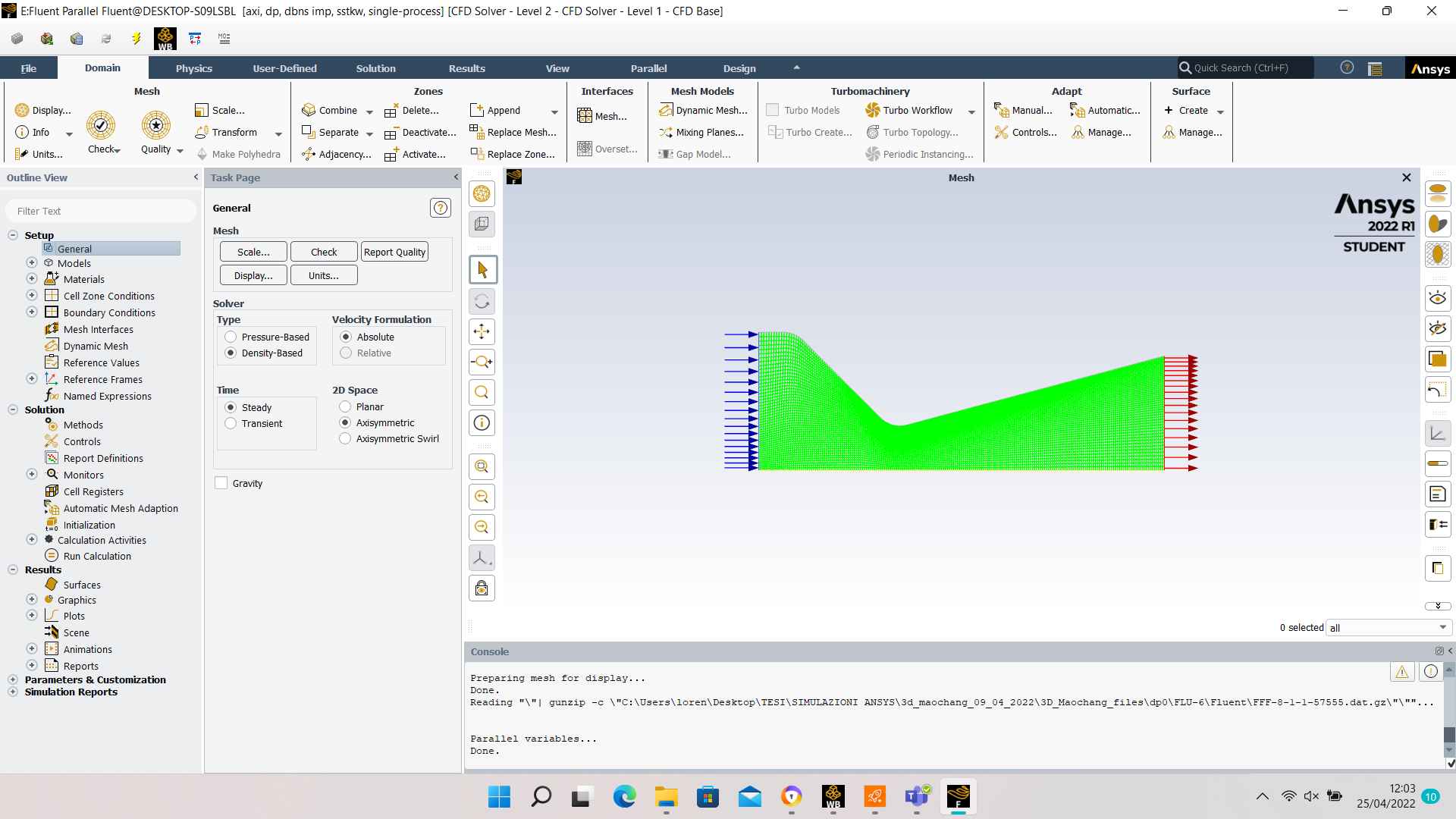

I have already asked a question related to the dpm concentration in a nozzle (/forum/discussion/35817/small-particles-gas-flow-in-a-nozzle#latest). Basically, I needed to inject some particles (20 micrometer of diameter) in a converging-diverging nozzle. Using a surface injection with a structured mesh 190x50 and 2d-axisymmetric geometry, I encountered a dpm concentration error (the dpm concentration in the cells near the axis was about 300 Kg/m^3, a clearly wrong value, while in the rest of the nozzle was about 2 kg/m^3). Thanks to your help, I found out that a possible solution was to use the "scale flow rate by surface area" option. Enabling this option allowed me to have a good and correct result, with no more wrong dpm concentration near the axis of the nozzle. However, by applying this strategy I cannot reach a uniform mass injection along the radius at the inlet of the nozzle, obviously beacuse in a 2d-axisymmetric simulation the volume of the cells near the axis is smaller than the volume of the outer cells. So the scaling of the particle flow rate by surface area resulted in a smaller mass of particles injected near the axis and a greater mass of particles injected in the outer region.

Now, I need to inject a uniform mass distribution all along the radius, so I cannot anymore apply the "scale flow rate by surface area". Are there other options to solve the dpm concentration problem?

I leave here some details about the simulation:

1) mass flow of the gas: 2.15 Kg/s

2) Mass flow of the particles: 0.92 Kg/s (more or less the 30% of the gas flow).

3) dpm model

4) surface inj (every parcel is injected from the centroid of the cell at the inlet along the radial direction)

5) B.C.:

Inlet: pressure inlet, P_tot= 1034000 Pa, T_tot= 555.6 K.

Outlet: Pressure outlet, non reflecting

Wall: specified shear all set to zero (in order to achieve a slip condition but with a real viscous flow), no heat flux, dpm trap.

April 25, 2022 at 2:26 pmRob

Forum ModeratorBecause of the 2d-axi approach I'm not sure you can do this: you'll either have a uniform concentration or mass. If you have a sector then you will inject on every surface facet so other than some distortion due to inflation at the outer radius you should be OK. 30-60 degrees should be a good compromise between cell count and skew at the axis.

April 29, 2022 at 8:29 amLorenzo_P

Subscriberhi Rob, thanks to your kind reply. So, what do you suggest? To keep the "scale flow rate by surface area"? Also I don't get your last sentence: what degrees are you referring to?

Moreover, I've realized that applying a "randomize starting point" and increasing the number of stream above 1000 allows to solve dpm concentration problems without using the "scale flow rate by surface area". Do you think this can be a good option?

April 29, 2022 at 4:37 pmRob

Forum ModeratorIt depends on what you want to do/see. Particle concentrations in 2d-axi systems aren't always easy to interpret.

Adding more parcels and randomising the starting point changes the injection: it's different and I can't say if it's better.

The 30-60 degrees comment is relating to modelling a 30 degree sector, ie a 3d model. This removes the problems of whether the injection mass weighting changes the concentration as the inlet can have a uniform injection as the facet areas are actually there in 3d. Too low an angle gives a skew cell at the axis, too large an angle means you use too many cells. Given swirl and gravity tend to feature in many models I tend to run the full 360 degree nozzle.

May 13, 2022 at 5:20 pmLorenzo_P

SubscriberSorry for the delay of my answers but I was very busy with work.

So, basically, you suggest to simulate a 30-degree sector of the nozzle.

To clarify, my first aim was to inject a uniform amount of mass flow rate of particles along the radial direction in a 2d-axisymmetric nozzle with uniform cells along the radial direction. This is why I have chosen the surface injection: at the centroid of each cell (which are radially uniform distruibuted), I wanted to have injected the same mass flow rate of particles (and therefore of parcels). However, as I was showing in the previous discussion we had in february, this seems not possible due to dpm concentration related problems, caused by, if I have understood well, the small volumes of the cells close to the axis, since the axisymmetric model "works" like it is dealing with a sector of the nozzle of about 5 degree ("wedge angle"). Is this correct?

The first solution you suggested in february was trying the "scale flow rate by surface area" option, which worked leading to a reasonable solution, but this method does not allow to have the same mass flow rate injected at the centroid of each cell.

So, the only way to have a uniform mass flow rate injected along the radial direction (i.e. the same mass flow injected at each centroid of the inlet cells, which are equally distributed along the radius) is to leave the axisymmetric geometry and instead model a 30 degree 3d sector of the nozzle.

Is this summary correct? Have I understood everything well?

Thank you again for your help, it is extremely precious.

Lorenzo

May 16, 2022 at 9:51 amRob

Forum ModeratorFluent works on an angle of Pi or 2Pi (it's in the manual and I can never remember) rather than 5 degrees in 2d axi-symmetric: that's CFX.

If you release a parcel from each facet (surface injection) you'll get equally weighted parcels which will mess with the DPM concentration. Partially because of the injection and partially because of the way Fluent works out DPM Concentration. The value is defined in the documentation. Using "scale by surface area" may even the injection out but may still give an uneven concentration due to the way the cell volume is calculated. Momentum transfer etc is correct, it's the Concentration that may be a bit misleading.

Going to 3d means you can have an (fairly) uniform facet size on the inlet which should mean the cell sizes are more uniform and therefore the concentration AND mass tie up. Using 30 degrees means you can have a decent cell shape at the axis and a sensible cell count.

I think we're both on the right track. DPM Concentration is an awkward one as it's cell volume based, so the result may be misleading.

May 16, 2022 at 10:17 amLorenzo_P

SubscriberReally clear, thank you.

I've also thought about giving to the cells a particular radial dimension so that the surface of each cell at the inlet is equal (so, the first cell near the axis will have a higher radial dimension with respect to the last cell near the wall). In this way, I should obtain equally weighted parcels even using "scale flow rate by surface area", since all inlet cell surfaces are equal. Is this true?

Obviously, this process should be replicated also at throat and outlet sections, so that the "radial cells distribution" remains the same along the nozzle.

However, by doing so, I will not have anymore a uniform injectors distribution, since every cell will have a different radial dimension and therefore the centroids will not be equally spaced along radius. To mitigate this issue, I tought to increase radially the number of cells and as a consequence of the injectors. The non-uniform injectors distribution will be still present but it should be somehow mitigated by this action.

Understanding that the 3d-method (30 degree sector) is the best and maybe the only one that gives a good result, what do you think about this idea?

Thank you again for your fundamental support,

Lorenzo

May 16, 2022 at 2:44 pmRob

Forum ModeratorMessing with the cell area will help but you need to be careful you don't over complicate things and mess up the resolution to get the flow right! Focussing on only one part of the problem is a really good way to mess up the simulation.

A 3d sector will reduce the problem. But, you're also adding a significant cell count to get the DPM Concentration so you need to decide if it's worth it. Have a look at the definition again, can you use a Custom Field Function to reduce the effect of the cell volume?

May 16, 2022 at 3:42 pmLorenzo_P

Subscriberok, now I'm trying, just to verify, the following scheme:

300 cells in radial direction, equal surface (every cell has a different radial dimension to match this requirement). I've replicated this process both in the throat and at outlet sections (so structured mesh).

900 cells in axial direction.

Surface injection at inlet.

Particle diameter = 20 microns; injection velocity = defined by udf as equal to the flow velocity; particle mass flow rate = 0.93 Kg/s (the gas mass flow is 2.17 Kg/s, the particle mass flow needs to be the 30% of the total mass flow); "SCALE MASS FLOW BY SURFACE AREA" = ON; Temperature = Total fluid temperature = 555.6 K; Drag law = defined by udf. These are the properties I need to impose for the particles.

B.C. : inlet = pressure inlet (P_tot=1034000 Pa, T_tot=555.6 K), outlet = pressure outlet, axis = axis, wall = slip condition (specified shear = 0), trap for particles.

As soon as I get a result, I will let you know if this method leads to some improvement of the results.

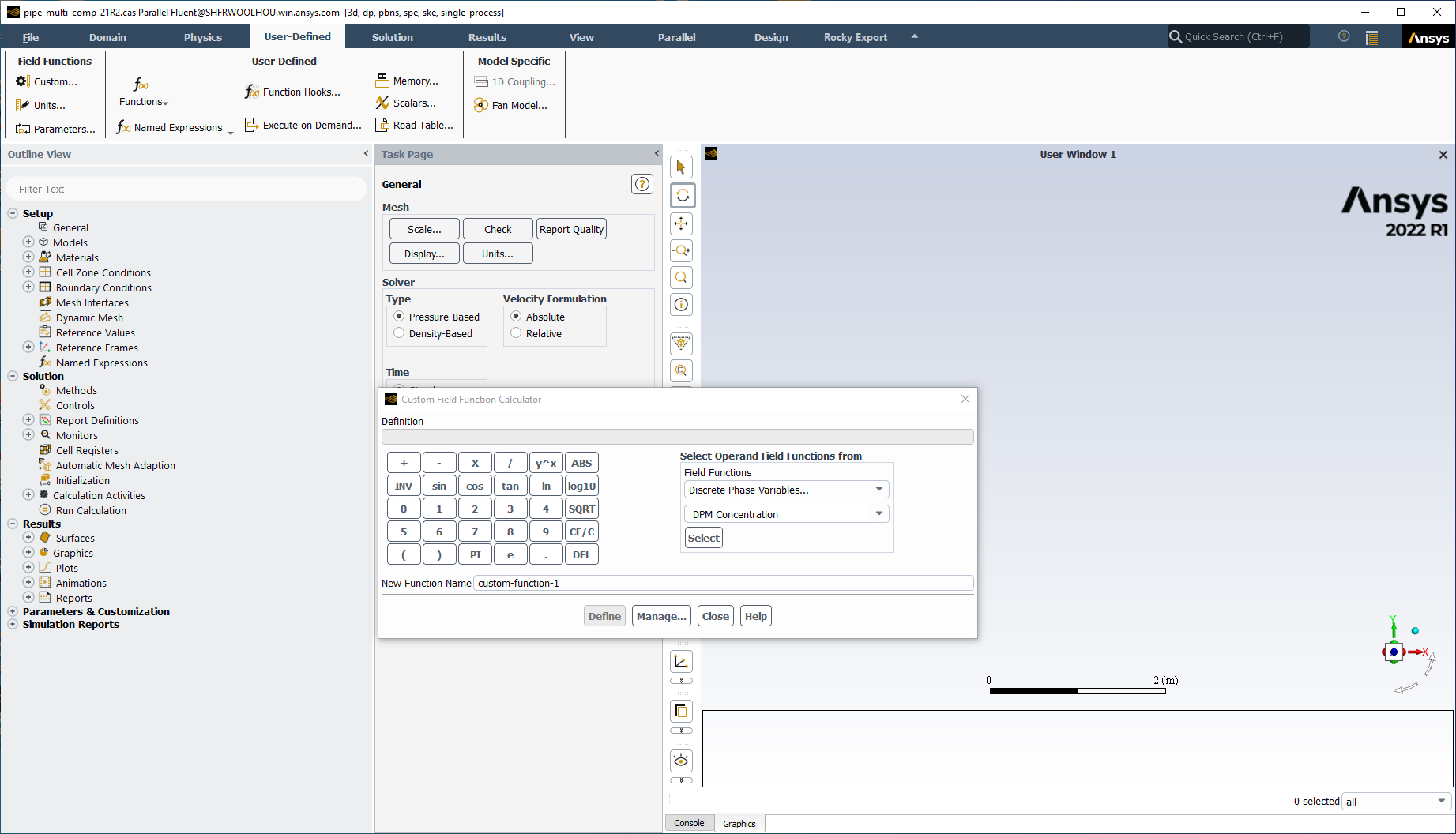

In the meanwhile, I have a doubt regarding your last question (Custom Field Function). What variable should I add / should I modify to reduce the effect of the cell volume over the computation of the particle concentration? And how can I manage/write it?

Moreover, I've found a paper where, regarding to dpm concentration problem in nozzles, the author explains: "One approach was to collect local mesh size information from the inlet, and redistribute a prescribed number of injection locations to be equally spaced between grid points, with mass flow rates for each particle stream proportional to the fraction of the inlet area occupied by the host cell. This approach was then improved by introducing random positions within each cell for each realization of dispersed phase solution, with particle mass flow rates proportional to the local radius at each single injection". However, I think, with this method he cannot obtain an equal mass of particles injected along the radius, since again he is simply adapting the injection to obtain a correct dpm concentration in the domain. Do you agree?

In the end, if no other options will be profitable, I will try the 3d sector, however I'm a bit afraid about the number of cells required, as you said.

Lorenzo

May 16, 2022 at 3:54 pmRob

Forum ModeratorRe the CFF - look at the DPM Concentration units and definition, how do we remove the dependence on area (volume)?

I think the paper is describing the "scale by area" option along with the random option.

Note, we're only supposed to point you at the buttons to press to do stuff; interpretation of results etc is in the grey area between helping and breaking the rules. We're very definitely in the grey area, so I may not be able to give a full answer.

May 16, 2022 at 4:18 pmLorenzo_P

SubscriberYes, no problem, really. I obviously repsect your guidelines, so I'm trying to ask but not "going too far", let's say. If there is something at which you cannot give an answer, again, no problem, I fully understand :) .

To sum up what we have said until now:

Trying to adapt the mesh (in terms of equal surface for each cell in radial direction) and by applying the "scale flow rate by surface area" could give some imporvements to the result, but at the same time it could mess up other aspect of the simulation. Now i'm trying this, but just as a test.

The 3d "sector" method will reduce the dpm concentration problem but the number of cells will increase a lot.

Maybe, by removing the dependence of the dpm concentration on the area/cell volume we could solve the problem. So now I'll check if through a Custom Field Function I'm able to do so.

As soon as points 1. and 3. will be complete, I'll give you and update!

Lorenzo

May 17, 2022 at 9:19 amRob

Forum ModeratorThanks. It's an awkward problem from our side, we're bound by US export law (I'm also bound by UK law) so can't share information that's not "public domain" or "obvious": the latter is the hard bit as I've been doing this a while so "obvious" to me might be quite advanced but our legal team aren't engineers....

You may want to look in the Mesh part of the Custom Field Functions.

May 17, 2022 at 11:02 amLorenzo_P

SubscriberYour help is still great and so appreciated even under those laws, I can assure you.

As I've found, the dpm concentration is compured as:

DPM concentration = (Avg. particle mass in cell * Part resi. Time * Strength of particle) / Cell volume

Strength of particle =total particle flow rate / mass of single particle in the stream

DPM conc. = (Avg. particle mass in cell * Part resi. Time * Total particle flow rate) / (mass of single particle in stream * cell volume)

Among the mesh variable of the Custom Field Function there is "cell-volume-2D" . Maybe, if I would be able to substitute the cell volume in the dpm concentration formula with this one, I could solve the problem. As I've understood, this variable means to compute the volume with a uniform depth and not by considering the 3d geometry behind the axial symmetry.

To calculate the DPM_concentration with a new formula (generally speaking), I just need to write the new formula in the Custom Field Functions space using the variables listed and then by activating the custom laws in the injection panel, am I correct?

Lorenzo

May 17, 2022 at 12:45 pmLorenzo_P

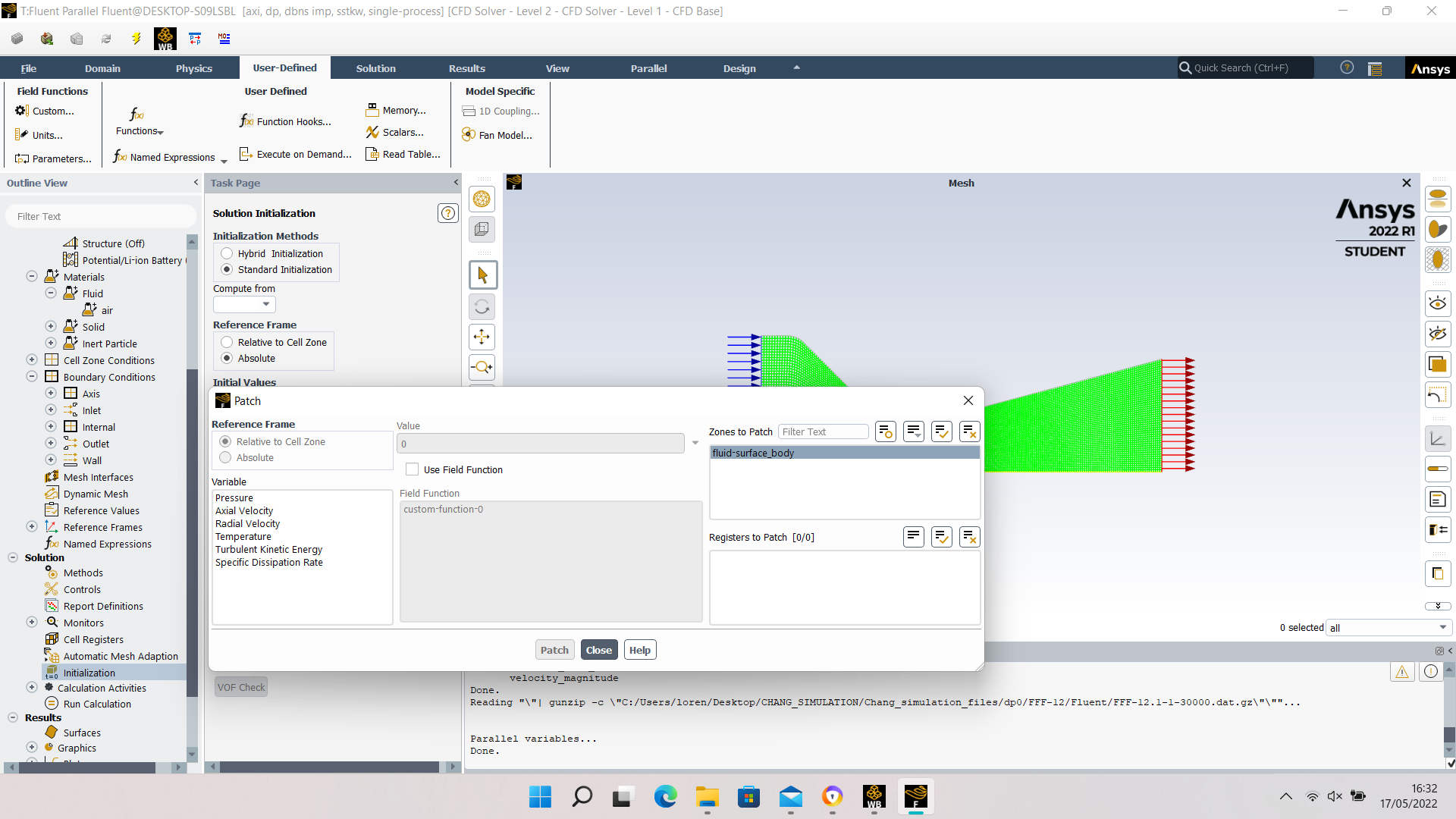

Subscriberok, sorry, by reading on the manual I've understood I need to use the patch dialog box. However, there, I cannot find the particle variables (such as dpm concentration), but only fluid variables. How can I initialize the different dpm concentration formula?

Lorenzo

May 17, 2022 at 1:48 pmRob

Forum ModeratorThe DPM values will need the particles to be coupled (interact with continuous phase) and only the flow side values will be present. It's a post processing step, so nothing to do with the custom laws: they're for messing with combusting particles (amongst other things).

May 17, 2022 at 2:42 pmLorenzo_P

SubscriberI have activated the coupling, but still I see only some fluid variables in the patch dialog box:

As you can see, There are only pressure, axial velocity, radial velocity, temperature and turbulence related variables. Is this what I should see or I'm missing something?

Or am i wrong and I should do a post-processing step to modify the way the dpm concentration is computed?

May 17, 2022 at 2:52 pmMay 17, 2022 at 2:58 pmLorenzo_P

Subscriberoh ok, clear. So should we start from the dpm concentration to compute something else using the inverse formula of dpm concentration? But what variable should I need to obtain from the new formula?

May 17, 2022 at 3:10 pmRob

Forum ModeratorMass per cell might be useful?

May 17, 2022 at 3:16 pmLorenzo_P

Subscriberyes, because I haven't access to this information, but then this mass per cell variable how can be used to mitigate the dpm concentration problem? My idea could be to found it as:

Avg. particle mass in cell = (DPM conc. *mass of single particle in stream * cell volume ) / (Part resi. Time * Total particle flow rate)

But since other variables are already defined, I am not sure what can change. Maybe should I use this formula but with the 2d-cell-volume instead of cell volume? I don't know if you can answer to this qeustion, but I try.

May 17, 2022 at 3:18 pmRob

Forum ModeratorI'd use Cell Volume and make sure I didn't touch the depth reference value.

I'd also look at the units in DPM Concentration https://ansyshelp.ansys.com/account/Secured?returnurl=/Views/Secured/corp/v221/en/flu_ug/flu_ug_fvdefs.html

May 17, 2022 at 3:22 pmLorenzo_P

Subscriberok, so, by computing the average particle mass in cell starting from the dpm concentration and not vice versa the concentration problem should be solved? Or I need to think at other steps?

May 17, 2022 at 3:24 pmRob

Forum ModeratorIt'll be a different problem, whether than solves your concentration issue is a different question!

May 17, 2022 at 3:30 pmLorenzo_P

SubscriberAh ok yes, beacuse I thought we were still discussing on how reduce the effect of the cell volume over the dpm concentration.

May 17, 2022 at 3:49 pmLorenzo_P

Subscriberso, now, trying to sum up all the suggestions that we have exchanged, I have a bit of confusion. Can I ask you a brief summary with the most improtant suggestions you gave me?

For example, the computing of the average mass per cell through the custom field function is useful, but then how I can use this information? And how can we reduce the impact of the cell volume over the dpm concentration ?

Thanks and sorry for the inconvenience.

Lorenzo

May 17, 2022 at 4:04 pmRob

Forum ModeratorYou have a problem with concentration as it's linked to the cell volume. Whilst the solver is working as intended you're then getting some results that are a little confusing: the inlet area, parcel mass etc make interpreting the results difficult. Plotting DPM MASS might resolve the issue as it may be more uniform/distributed and avoid looking at 3D. Note, I can't remember how Fluent calculates cell volume in 2d-axi so plot the value and see how it's accounting for the swept volume.

May 17, 2022 at 4:48 pmLorenzo_P

SubscriberGreat, I'll try, again thank you

Lorenzo

Viewing 26 reply threads- The topic ‘solid particles in a nozzle, dpm concentration’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4909

-

1598

-

1386

-

1242

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-