-

-

December 11, 2018 at 8:50 pm

daniela

SubscriberHey everyone,

I'm right now trying to simulate the inflow in a rainwater channel. Therefore I've chosen the Eulerian Multi Fluid model, with air as phase 1, water as phase 2.

As my boundary condition for the inlet I've chosen a mass flow inlet. I've set 0 kg/s for air and 12.5 kg/s for water with a volume fraction of 1.

I've done a initialization from the inlet and the velocity is generated correctly. After the calculation the post-processing shows a mass flow of max 6e-1 kg/s/m2 at the inlet instead of the set 12.5 kg/s (the area is about 0.088 m2, so it should be aroung 143 kg/s/m2).

Can anyone tell me how this is possible? Is it not possible to choose a mass flow inlet in a VOF model? Or could there be another reason?

Thanks in advance,

Regards.

Daniela

-

December 11, 2018 at 9:50 pm

Amine Ben Hadj Ali

Ansys Employee1/Is it 2D or 3D?

2/How are you doing the post-processing?

3/Can you confirm that you are using the Eulerian Model?

Share screenshots of the models and of the boundary (bulk and phase) and post-processing.

-

December 12, 2018 at 4:15 am

Keyur Kanade

Ansys Employeealso please share screen shots of outlet boundary conditions, models used, other set up etc.

-

December 12, 2018 at 6:36 pm

-

December 12, 2018 at 6:52 pm

Amine Ben Hadj Ali

Ansys EmployeeWhat you are now post-processing is just the mass-flux applied at the boundary. You can imagine that Fluent will scale your input of mass-flow at with facets at your inlet so you will see that variation: Fluent divide your 12 kg/s by the water density and total area of inlet to get the normal velocity. What you are now showing is this normal velocity times density divided by the facet area. More important to verify under Report that the mass flow rate for the mixture and water-phase is what you provided as a boundary condition.

-

December 12, 2018 at 7:15 pm

daniela

SubscriberThanks for the quick response!

I think I got the calculation of the flux and flow. But as my area of the inlet is only 0.088 m2, I was thinking of a flux of about 143 kg/s/m2.

I've attached the report in the bottom, but I didn't see any specifications on the mass flow there.

Thanks in advance,

best regards,

Daniela

Fluent

Version: 3d, pbns, eulerian, rngke, transient (3d, pressure-based, Eulerian, RNG k-epsilon, transient)

Release: 19.2.0

Title:

Models

Model Settings

Space 3D

Time Unsteady, 1st-Order Implicit

Viscous RNG k-epsilon turbulence model

Wall Treatment Standard Wall Functions

RNG Differential Viscosity Model Disabled

RNG Swirl Dominated Flow Option Disabled

Multiphase k-epsilon Models Mixture k-epsilon

Heat Transfer Disabled

Solidification and Melting Disabled

Species Disabled

Coupled Dispersed Phase Disabled

NOx Pollutants Disabled

SOx Pollutants Disabled

Soot Disabled

Mercury Pollutants Disabled

Material Properties

Material: water-liquid (fluid)

Property Units Method Value(s)

Density kg/m3 constant 998.2

Cp (Specific Heat) j/kg-k constant 4182

Thermal Conductivity w/m-k constant 0.6

Viscosity kg/m-s constant 0.001003

Molecular Weight kg/kmol constant 18.0152

Thermal Expansion Coefficient 1/k constant 0

Speed of Sound m/s none #f

Material: air (fluid)

Property Units Method Value(s)

Density kg/m3 constant 1.225

Cp (Specific Heat) j/kg-k constant 1006.43

Thermal Conductivity w/m-k constant 0.0242

Viscosity kg/m-s constant 1.7894e-05

Molecular Weight kg/kmol constant 28.966

Thermal Expansion Coefficient 1/k constant 0

Speed of Sound m/s none #f

Material: aluminum (solid)

Property Units Method Value(s)

Density kg/m3 constant 2719

Cp (Specific Heat) j/kg-k constant 871

Thermal Conductivity w/m-k constant 202.4

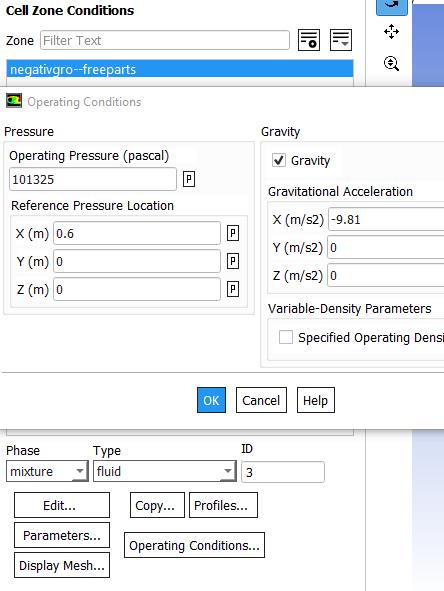

Cell Zone Conditions

Zones

name id type

negativgro--freeparts 3 fluid

Setup Conditions

negativgro--freeparts

Condition Value

Frame Motion? no

Mesh Motion? no

Boundary Conditions

Zones

name id type

inlet 6 mass-flow-inlet

wall-negativgro--freeparts 1 wall

outlet 7 pressure-outlet

wall1 8 wall

wall2 9 wall

wall3 10 wall

wall4 11 wall

wall5 12 wall

wall6 13 wall

Setup Conditions

inlet

Condition Value

wall-negativgro--freeparts

Condition Value

Wall Motion 0

outlet

Condition Value

wall1

Condition Value

Wall Motion 0

wall2

Condition Value

Wall Motion 0

wall3

Condition Value

Wall Motion 0

wall4

Condition Value

Wall Motion 0

wall5

Condition Value

Wall Motion 0

wall6

Condition Value

Wall Motion 0

Solver Settings

Equations

Equation Solved

Flow yes

Volume Fraction yes

Turbulence yes

Numerics

Numeric Enabled

Absolute Velocity Formulation yes

Unsteady Calculation Parameters

Time Step (s) 10

Max. Iterations Per Time Step 5

Relaxation

Variable Relaxation Factor

Pressure 0.3

Density 1

Body Forces 1

Momentum 0.7

Volume Fraction 0.5

Turbulent Kinetic Energy 0.8

Turbulent Dissipation Rate 0.8

Turbulent Viscosity 1

Linear Solver

Solver Termination Residual Reduction

Variable Type Criterion Tolerance

Pressure V-Cycle 0.1

X-Momentum Flexible 0.1 0.7

Y-Momentum Flexible 0.1 0.7

Z-Momentum Flexible 0.1 0.7

Volume Fraction Flexible 0.1 0.7

Turbulent Kinetic Energy Flexible 0.1 0.7

Turbulent Dissipation Rate Flexible 0.1 0.7

Pressure-Velocity Coupling

Parameter Value

Type Phase Coupled SIMPLE

Discretization Scheme

Variable Scheme

Pressure Second Order

Momentum First Order Upwind

Volume Fraction Compressive

Turbulent Kinetic Energy First Order Upwind

Turbulent Dissipation Rate First Order Upwind

Solution Limits

Quantity Limit

Minimum Absolute Pressure 1

Maximum Absolute Pressure 5e+10

Minimum Temperature 1

Maximum Temperature 5000

Minimum Turb. Kinetic Energy 1e-14

Minimum Turb. Dissipation Rate 1e-20

Maximum Turb. Viscosity Ratio 100000

-

December 12, 2018 at 7:25 pm

Amine Ben Hadj Ali

Ansys Employee -

December 13, 2018 at 10:46 am

daniela

Subscriber"mfr_air_inlet-rfile"

"Time Step" "mfr_air_inlet etc.."

("Time Step" "mfr_air_inlet" "flow-time")

0 0 0

1 0 10

2 0 20

3 0 30

4 0 40

5 0 50

6 0 60

7 0 70

8 0 80

9 0 90

10 0 100

11 0 110

12 0 120

13 0 130

14 0 140

15 0 150

16 0 160

17 0 170

18 0 180

19 0 190

20 0 200

"mfr_mixture_inlet-rfile"

"Time Step" "mfr_mixture_inlet etc.."

("Time Step" "mfr_mixture_inlet" "flow-time")

0 12.49999999999998 0

1 12.49999999999998 10

2 12.49999999999998 20

3 12.49999999999998 30

4 12.49999999999998 40

5 12.49999999999998 50

6 12.49999999999998 60

7 12.49999999999998 70

8 12.49999999999998 80

9 12.49999999999998 90

10 12.49999999999998 100

11 12.49999999999998 110

12 12.49999999999998 120

13 12.49999999999998 130

14 12.49999999999998 140

15 12.49999999999998 150

16 12.49999999999998 160

17 12.49999999999998 170

18 12.49999999999998 180

19 12.49999999999998 190

20 12.49999999999998 200

"mfr_water_inlet-rfile"

"Time Step" "mfr_water_inlet etc.."

("Time Step" "mfr_water_inlet" "flow-time")

0 12.49999999999998 0

1 12.49999999999998 10

2 12.49999999999998 20

3 12.49999999999998 30

4 12.49999999999998 40

5 12.49999999999998 50

6 12.49999999999998 60

7 12.49999999999998 70

8 12.49999999999998 80

9 12.49999999999998 90

10 12.49999999999998 100

11 12.49999999999998 110

12 12.49999999999998 120

13 12.49999999999998 130

14 12.49999999999998 140

15 12.49999999999998 150

16 12.49999999999998 160

17 12.49999999999998 170

18 12.49999999999998 180

19 12.49999999999998 190

20 12.49999999999998 200

The flow rates seem to be correct (I've chosen different time steps now). But the CFD Post is still showing the same for the flux. Is there any possibility to check the surface area in fluent? If I check it in DM it says 0.088 m2. And if I divide 12.5 kg/s by 0.088 m2, it should be 142 kg/s/m2, right?

Could be that I got this wrong somehow.

Best regards,

Daniela -

December 13, 2018 at 12:17 pm

Rob

Forum ModeratorIn Fluent go to the Surface Integrals (Post Processing and/or Reports), one of those gives area.

-

December 13, 2018 at 12:20 pm

Amine Ben Hadj Ali

Ansys Employee1/Is the contour plot from CFD-Post? Then please go to Calculators and make an area average of it at your Inlet

2/Area inf Fluent: Reports>Surface Integral>Choose Area and then your boundary

-

December 13, 2018 at 1:35 pm

-

December 13, 2018 at 1:57 pm

Amine Ben Hadj Ali

Ansys EmployeeIn CFD-Post make Area Integral of Mass Flow at the inlet. Does it fit your 12 kg/s?

-

December 13, 2018 at 2:04 pm

-

December 13, 2018 at 2:08 pm

Amine Ben Hadj Ali

Ansys EmployeeCan you please go back to Fluent and check there 2. In Fluent I am not aware about such a variable called mass flow but with dimension of flux.

Are you working with *.dat file in CFD-Post or with *.cdat file? Which version are you using?

-

December 13, 2018 at 2:21 pm

daniela

SubscriberIn Fluent I can't find the variable mass flow.

I'm using version 19.2, and for CFD-Post it's *.cdat.

Best regards,

Daniela

-

December 13, 2018 at 2:26 pm

Amine Ben Hadj Ali

Ansys EmployeeHi,

That is what I've actually said: there is no variable called mass flow in Fluent. That is only what CFD-Post does understand when it comes into calculating mass flow based on mass flow variable. In multi-phase runs CFD-Post will try to calculate the integrated mass-flow (your input) based on that variable (which is kg/m^2s). Please build the sum of the variable "mass flow" in CFD-Post. I would say it would match the 12 kg/s.

-

December 13, 2018 at 2:33 pm

Amine Ben Hadj Ali

Ansys EmployeeThere is no benefit for me to post-process this quantity. An integral report is better or getting contour of velocity and if compressible the density on the inlet is more appropriate.

-

December 13, 2018 at 2:39 pm

daniela

SubscriberThis fits. Thank you!

Then there's another thing I don't understand: If I have 12.5 kg/s of inflow and I did run the calculation for 200 s, how is it possible, that the water only reached the point in the graphics (the canal has a length of 1m, so 0.088 m3). With a inflow of 12.5 kg/s of water it should be 2500 kg (or liter) after 200s, which is way more than the volume of the canal. Might be, that I misunderstand the contour "volume fraction".

Thanks in advance,

best regards.

Daniela -

December 13, 2018 at 2:55 pm

Amine Ben Hadj Ali

Ansys EmployeeContour might be correct but as we do not have any idea about your model any comments will be only given by suspicion. We require some informations about your Case: Which boundaries are included and where?

From the plot it looks after a sort of open channel flow (?) where the water flow is sub-critical and that is why the height is decreasing. Check if you have an outlet if water reached that outlet. Moreover post screenshot of Fluent Residuals.

It might be that water reached a level far away but due to coarse resolution the whole vof field is smeared..

-

December 13, 2018 at 4:47 pm

daniela

SubscriberBasically water is filled in an small open container and it should flow into another bigger container with open surface before getting into a pipeline. To model the open surface I've set atmospheric pressure at the top.

The big tank has a volume of 2.5 m3, that's why I'm only simulating 200s right now, because I just wanted to see how the water reaches the end of the big container.

I have already decreased the maximum of the volume fraction contour, but it still doesnt reach the end of the container or the pipe.

Thanks.

Best regards,

Daniela

-

December 13, 2018 at 4:54 pm

Amine Ben Hadj Ali

Ansys Employee1/Ensure deep convergence every time step. From residual plot your run is not looking as it should. Share with us settings in FLUENT.

2/work with FLUENT post processing to avoid any issues. -

December 13, 2018 at 4:59 pm

Amine Ben Hadj Ali

Ansys EmployeeEnsure gravity is set properly and free surface is set as symmetry or free slip wall. Include a air layer above water at inlet in case you want to use pressure boundary at top

-

December 13, 2018 at 5:04 pm

daniela

SubscriberThanks!

Is there a way to ensure convergence or do I just have to increase the number of iterations?

Best regards.

-

December 13, 2018 at 5:14 pm

Amine Ben Hadj Ali

Ansys EmployeeRather smaller time step size and not more than max. of 20 iterations per time step.

Post screenshot Of solution methods and operating conditions -

December 13, 2018 at 5:23 pm

-

December 13, 2018 at 6:28 pm

Amine Ben Hadj Ali

Ansys EmployeePlease use VOF model with implicit volume fraction and give thai density as operating density. Eulerian model for this case is too complicated

-

December 13, 2018 at 6:34 pm

daniela

SubscriberOkay.

Which density should I set as operating density? Water or air?

Best regards,

Daniela

-

December 13, 2018 at 7:07 pm

Amine Ben Hadj Ali

Ansys EmployeeGive air as first approximation -

December 13, 2018 at 7:18 pm

Amine Ben Hadj Ali

Ansys EmployeeCheck this

-

- The topic ‘Mass flow inlet in Eulerian VOF model’ is closed to new replies.

-

4803

-

1582

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.