TAGGED: ansys-cfd, drag-coefficient, fluent, sphere

-

-

May 23, 2024 at 8:22 am

Zayn Zai

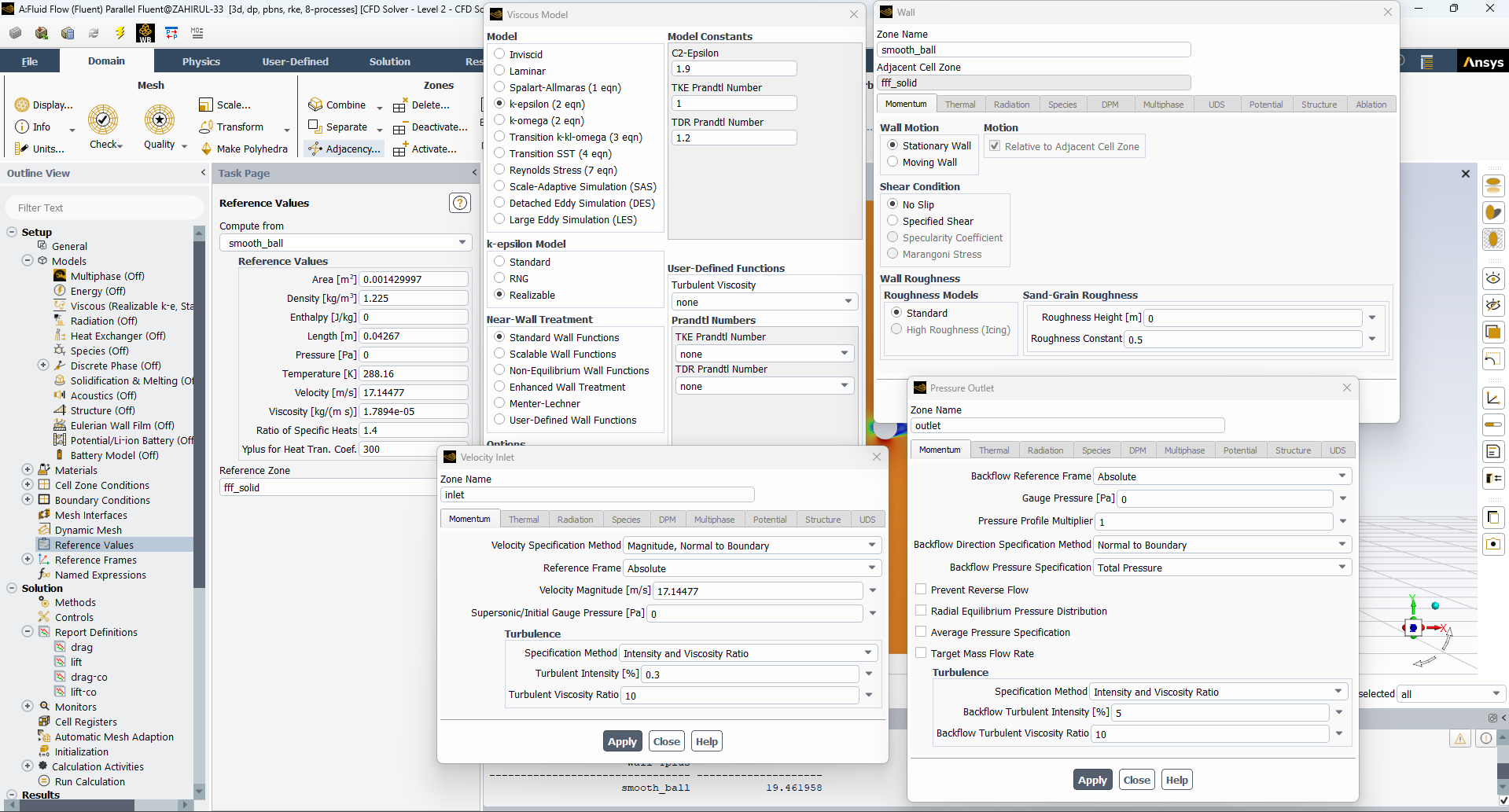

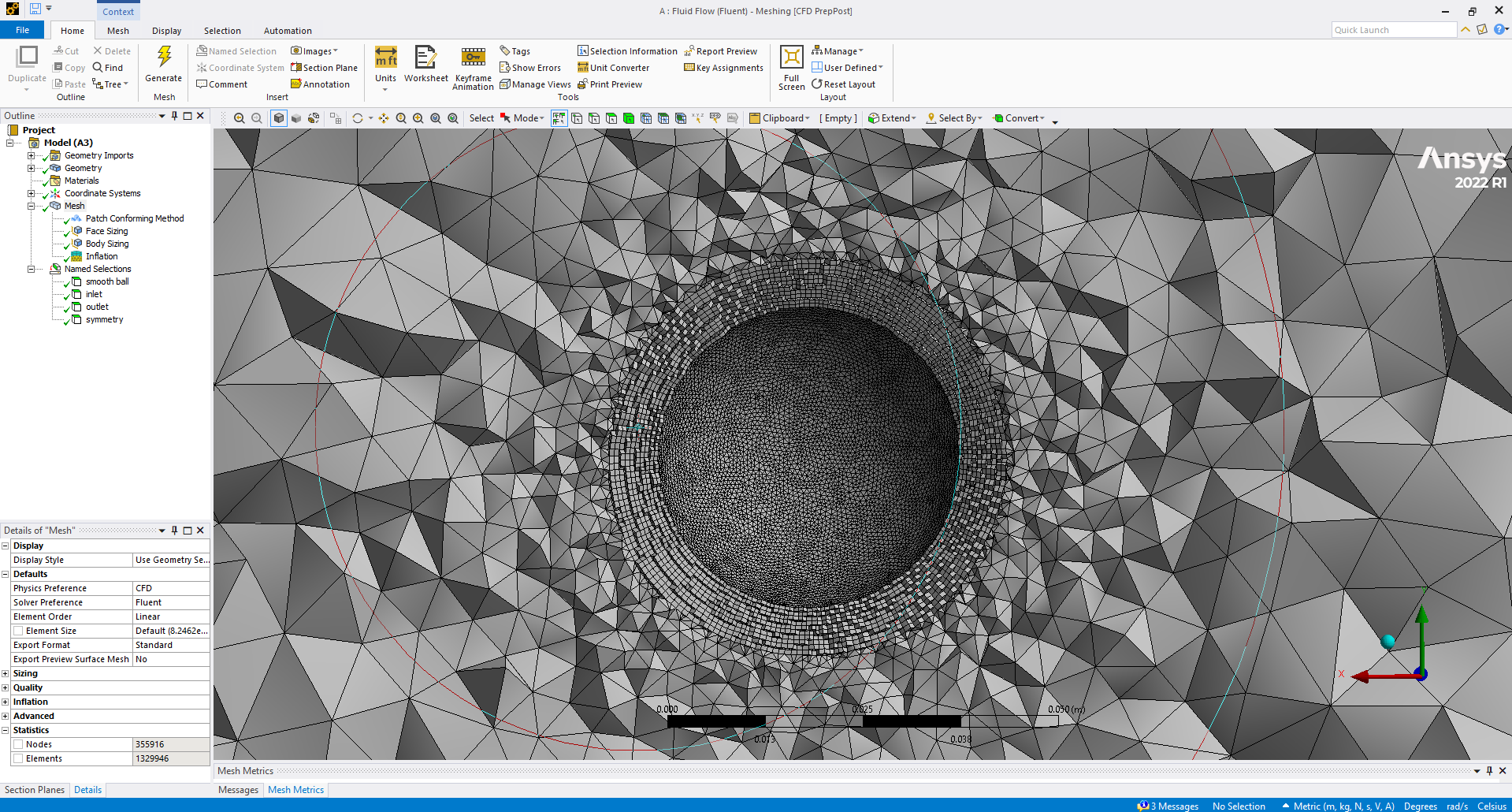

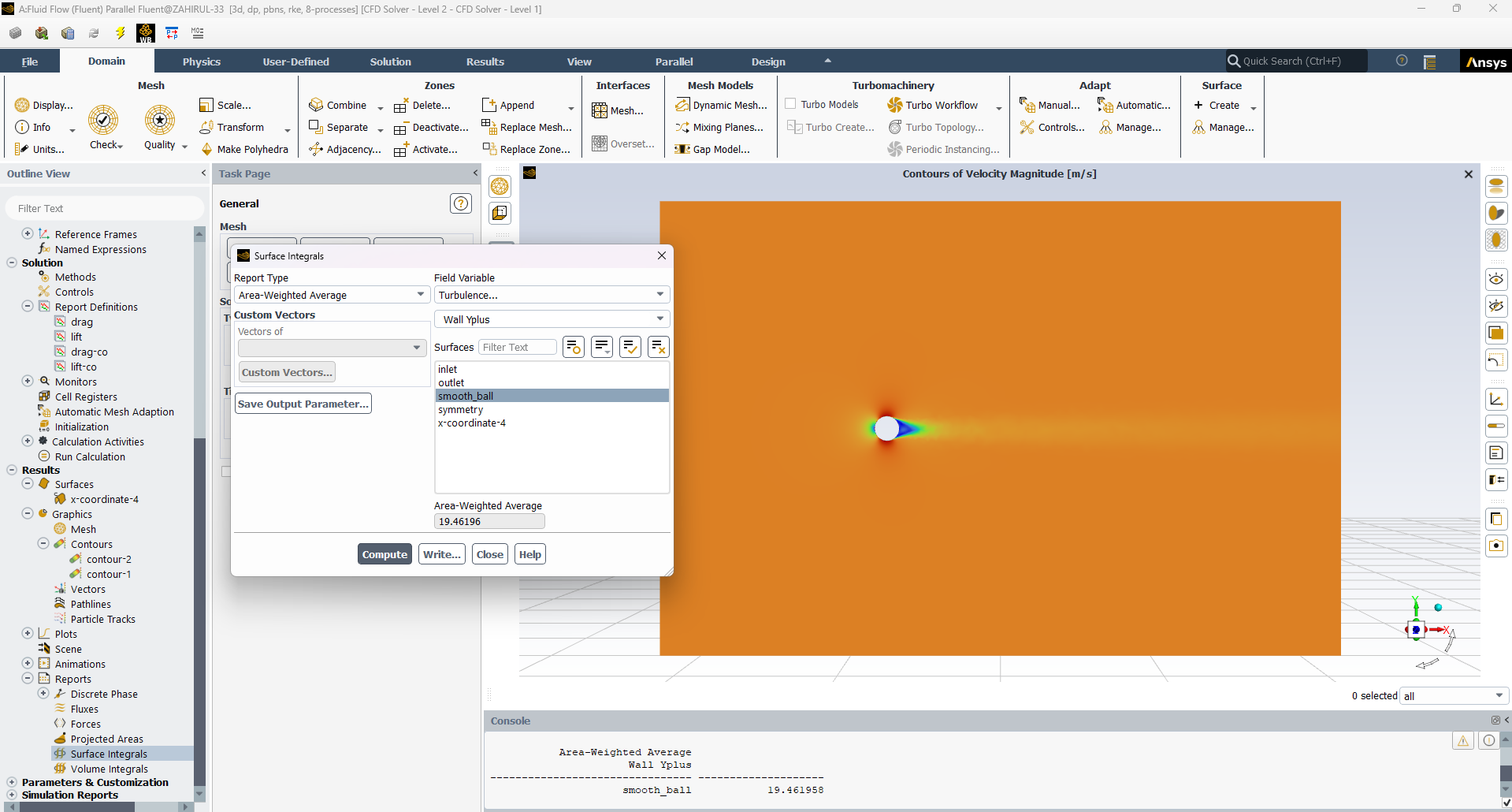

SubscriberI am conducting a simulation of a smooth sphere traveling through a flow to compare with experimental results. However, the drag coefficient obtained from the simulation is significantly lower (Cd = 0.11426044) compared to the experimental Cd of 0.45. The reference value settings are correctly adjusted, making it less likely the cause of the issue. I tried refining the mesh by decreasing the face and body sizing of the sphere and domain, but the Cd value still does not match the experimental results. I also adjusted the wall y+ value using the inflation of 10 layers with the first layer cell height obtained from the wall y+ calculator, which gave me a first layer height of 0.000738208399739557 m corresponding to wall y+ = 50. I need a wall y+ value between 30 and 200 as I am using the realizable k-epsilon model. However, when I calculate the wall y+ of the sphere in Fluent, it only shows 19. Can anyone tell me what I am doing wrong? link to Y+ calculator: https://volupe.se/wall-y-calculator-when-meshing-a-geometry-for-cfd-analysis-this-handy-volupe-calculator-computes-the-height-of-the-first-mesh-cell-off-the-wall-required-to-achieve-a-desired-y-using-flat-plate-boun/

-

May 27, 2024 at 4:45 pm

Essence

Ansys EmployeeHello,

Any reason for not using polyhedra or hexahedral mesh instead of tetrahedral? Can you try with y+ in order of 1? I mean 0.2 < y+ < 5. I say this because, you need be careful as to NOT have the y+ in buffer layer.

-

May 28, 2024 at 4:30 am

Zayn Zai

SubscriberHi Essence, thanks for your reply. I reduced the inflation cell height and added more layers, which resulted in a Y+ value of 1.03. However, despite these changes, the drag coefficient I obtained was 0.32, which was lower than the experimental result of 0.45. I attempted using the SST k-w turbulence model as recommended by my research, but encountered convergence issues when employing the coupled method. Switching to the SIMPLEC method resolved the convergence issue, but the drag coefficient remained low. As for why I'm using tetrahedral mesh, It is because I have read somewhere that tetrahedral are more suitable for curve surfaces which in this case is the surface of the sphere. Does using polyhedral or hexahedral meshes could improve accuracy? I'm relatively new to Fluent, I lack the expertise to determine the optimal mesh type for my simulation.

-

-

May 28, 2024 at 7:25 am

Essence

Ansys EmployeeYes, definitely. If not hexaherdal, polyhedra mesh provides superior accuracy and stability while simulating the case compared to tetrahedral. You might need to use Fluent meshing which is suited for Fluent solver. Please refer Ansys guide for more information on Fluent meshing. I hope this will prevent the convergence issues while using k-w SST and coupled solver. Please maintain minimum orthogonal quality more than 0.15 and overall growth rate in entire domain less than 1.2. Watch out for the flow separation on cylinder surface. Use Intermittent transition model if required. Most importantly, be careful of the reference values you input, since these values are directly used for calculating drag coefficient.

-

May 28, 2024 at 11:00 am

Jim Beet

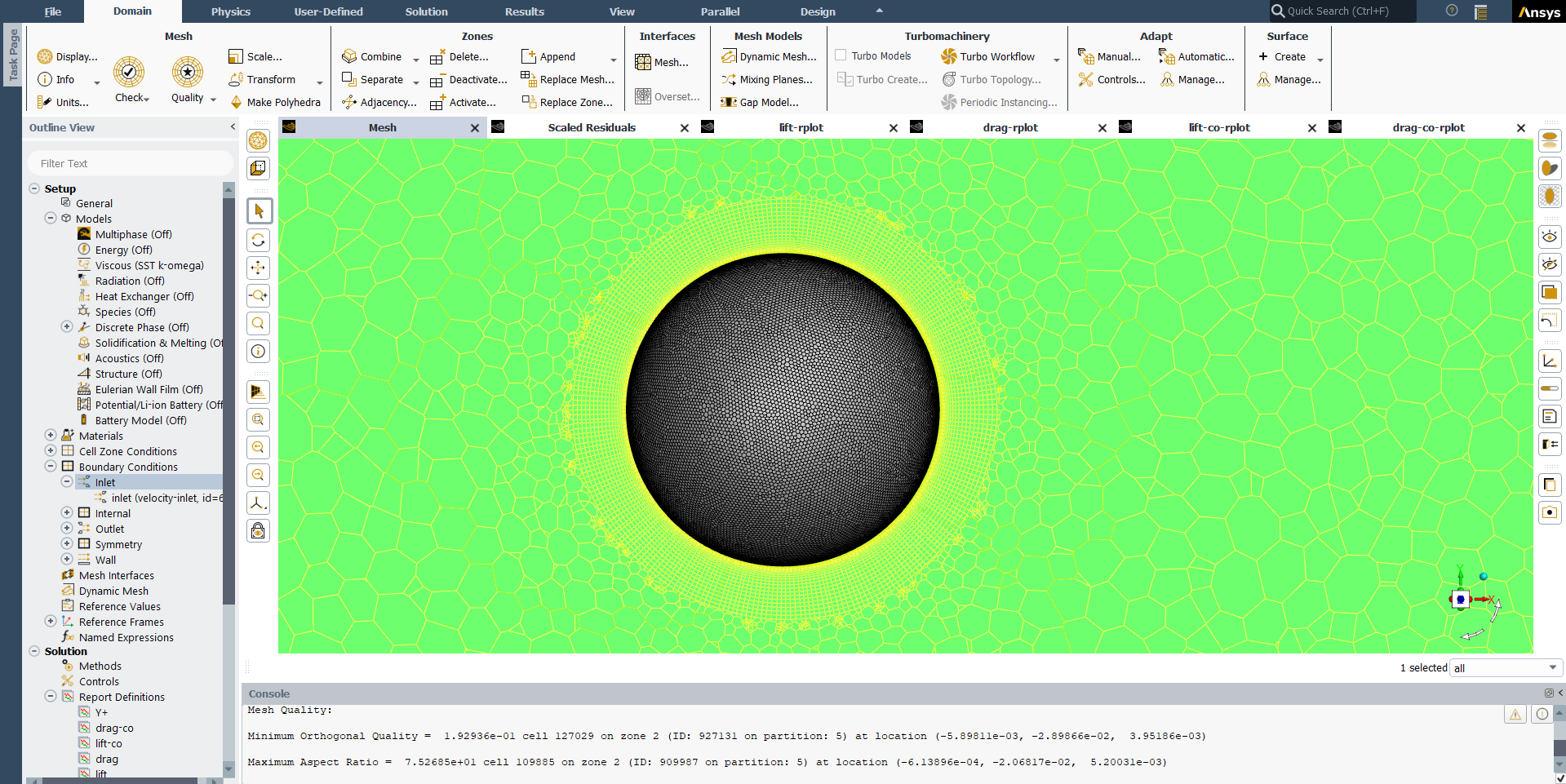

SubscriberHow do I check the overall growth rate of my domain? I tried using the polyhedral mesh with min orthogonal quality of 0.19 but the drag coefficient is still far from the experimental value. Decreasing the element size of the mesh seems to not have that much effects as the drag coefficient varies between 0.2 and 0.3 not exceeding this value. my mesh and setup are as below:

-

-

May 28, 2024 at 11:35 am

Essence

Ansys EmployeeYou can observe the growth rate while generating the mesh in Fluent while using polyhedra mesh. If you are simulating steady case, turn ON the High Order Term Relaxation and Psuedo time in Methods section. Again, use Intermittent transition if flow separation occurs. Try using Coupled instead of SIMPLEC.

-

May 30, 2024 at 8:53 am

Zayn Zai

SubscriberHi essence please reply, I need your help for this issue

-

-

May 28, 2024 at 12:35 pm

Jim Beet

SubscriberCan the growth rate be observe in ANSYS meshing because I used this to create the tetrahedral mesh. The polyhedral mesh, was generated using the " make polyhedral" function in Fluent. As for the intermittent transition, how do I use this feature in FLUENT? thanks in advance.

-

May 30, 2024 at 9:04 am

-

- The topic ‘Low drag coefficient for sphere’ is closed to new replies.

-

2979

-

970

-

857

-

750

-

599

© 2025 Copyright ANSYS, Inc. All rights reserved.