-

-

October 1, 2024 at 1:41 pm

Hilal Çelik

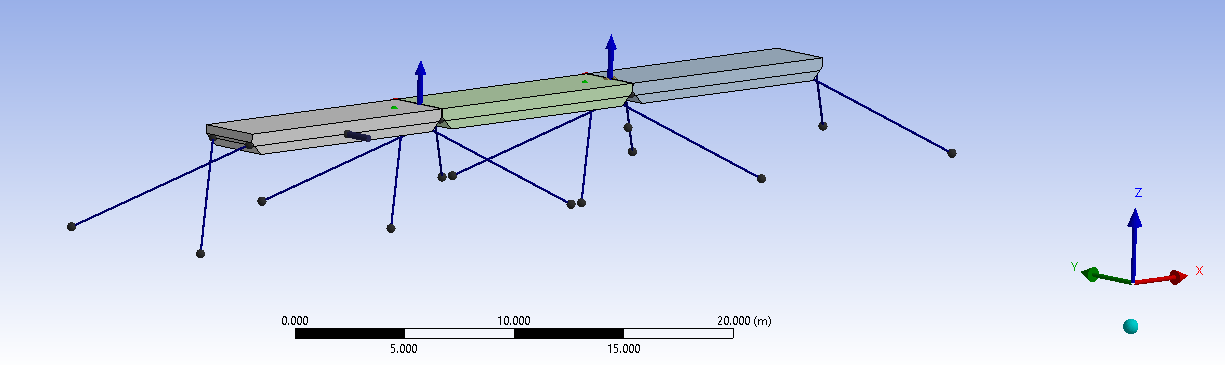

Subscriberhi, I try to linear elastic cables but I meet the error text. The floating pontoon models and mooring lines can be seen in the first picture. The joint types are hinged but I change the second joint as ball and socket joint to get rid of the errors but it didn't help. What is the solution for this error?

-

October 3, 2024 at 11:40 am

Shuangxing Du

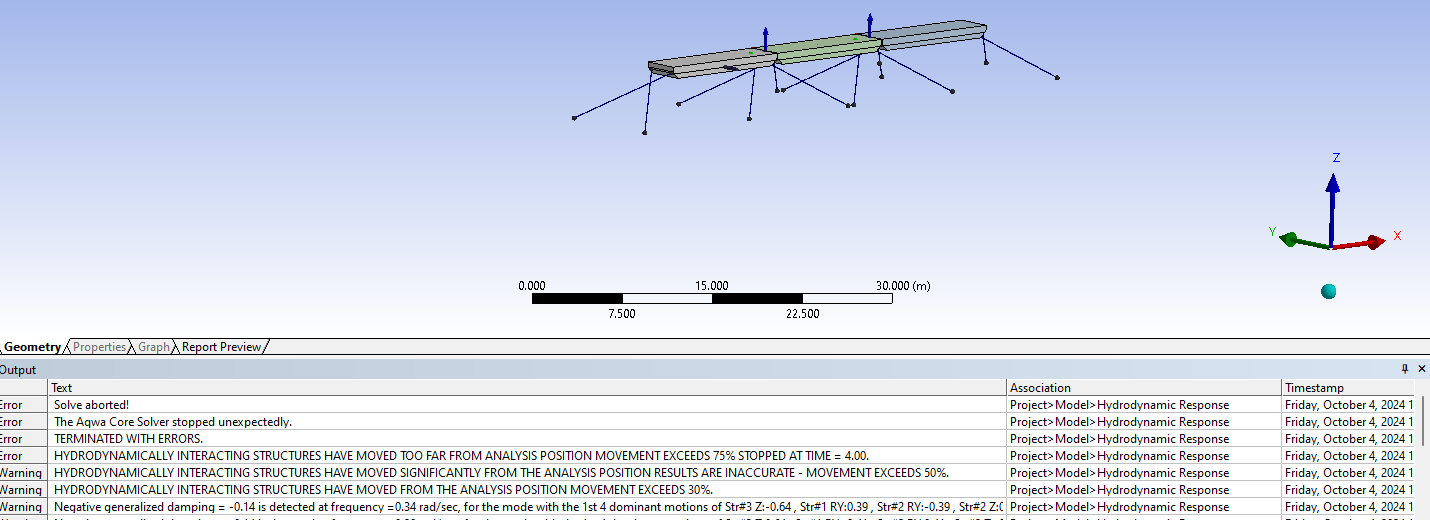

Ansys EmployeeFor a hydrodynamic interaction group of structures, the hydrodynamic properties are sensitive to the relative positions of the structures. In Aqwa time domain analysis the relative positions of some selected pairs of diffraction elements between adjacent structures are checked and compared to the relative positions defined in the Hydrodynamic Diffraction analysis. If the changes are too big in the time domain simulation, error message will be issued.

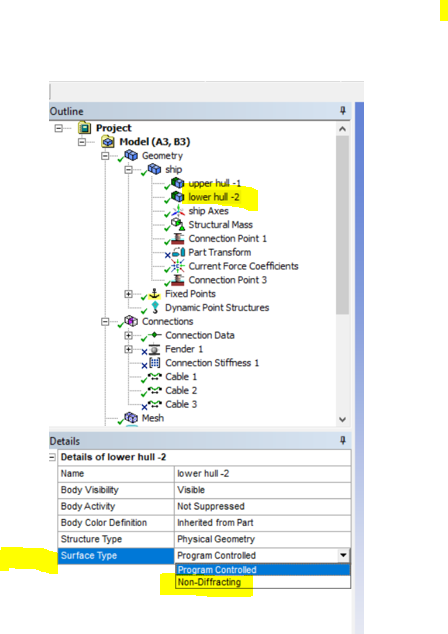

In your model, are the gaps between the structures too narrow? If yes, can you set the surfaces of structures of which they face to each other as non-diffraction surface before meshing?

The socket joint (which allows the relative yaw and roll motions) may make the situation even worse.

-

October 4, 2024 at 5:54 am

Hilal Çelik

SubscriberThanks for your help. The gaps between the pontoons are 40 mm, yes they are too small. How can I set the faces as non-diffraction surfaces?

-

October 4, 2024 at 8:25 am

-

October 4, 2024 at 8:35 am

-

October 4, 2024 at 10:55 am

abubakarumar1097

SubscriberHi! It sounds like you're facing issues with your floating pontoon models and mooring lines. Here are a few suggestions to troubleshoot the error:

Check Constraints: Ensure all joints are properly defined and compatible with the linear elastic cables you're using.

Review Connections: Confirm that all connections between the pontoon and mooring lines are correctly set up.

Joint Settings: Double-check the settings for the ball and socket joint. Make sure it’s configured to allow the necessary degrees of freedom.

Model Scale: Ensure the scale of your model is appropriate; sometimes, very small or large scales can lead to unexpected behavior.

Software Documentation: Refer to the software’s documentation or forums for specific guidance on the error message you’re receiving.

If the problem persists, providing the specific error text could help diagnose the issue further. Good luck!

-

October 4, 2024 at 12:24 pm

Hilal Çelik

Subscriberactually, I changed the joint type, to hinged connections.

-

October 4, 2024 at 1:02 pm

fakhrafakhrifakhru

SubscriberIt might be with how the mooring lines or cable connections are modeled. Changing the joint type to a ball and socket could be a good step, but you may also need to check if the cable properties, boundary conditions, or loading setup are properly defined. Ensure that the cables are correctly assigned as "linear elastic" and that all constraints are compatible with the floating pontoon's movement. Additionally, try reviewing the error message details, as they can provide specific clues about what is causing the problem.

-

October 16, 2024 at 3:51 pm

mugheesaslam12

SubscriberHi! It sounds like you're encountering issues with the mooring line modeling. Since changing the joint type to a ball and socket didn't solve the problem, the error might be related to the linear elastic properties of the cables or the constraints applied to them. Check if the material properties and boundary conditions of the cables are set up correctly. can you guess How old is Hope Violet Garrett? Also, ensure that the model's degrees of freedom are properly constrained. If the issue persists, try simplifying the model or increasing the simulation's tolerance settings to see if that resolves the error.

-

October 18, 2024 at 7:24 am

Hilal Çelik

Subscriberthanks for all your help. I changed the joint type to ball and socket and it did work but I don't understand why it didn't work when they are hinged-type and how I change the tolerance of the simulation?

-

October 31, 2024 at 2:12 am

kholivt88

SubscriberHere are a few troubleshooting steps you can try:

Check Joint Connectivity: Ensure that all joints are correctly connected to the cables and that there are no overlapping elements that might cause conflicts.

Review Cable Properties: Double-check the properties of your linear elastic cables. Make sure the material parameters are correctly defined and that they match the requirements for your simulation.

Simplify the Model: If possible, simplify the model by temporarily removing some elements to isolate the issue. This can help identify if a specific part of the model is causing the error.

Adjust Joint Types: While switching to a ball and socket joint can help, consider reverting to hinged joints for all connections if you encounter issues with other types.

Consult Documentation: Refer to the software documentation or user forums for specific error messages. There might be known issues or recommended fixes related to your setup.

If these steps don't resolve the issue, providing more details about the specific error message might help in diagnosing the problem further. Good luck!

-

March 10, 2025 at 9:57 am

lunaserena151

SubscriberErrors with multi-connected bodies in AQWA can be tricky, often caused by incorrect constraints or mesh issues. These problems can mess up simulations, making it hard to get accurate results. It’s like checking "Texas Roadhouse Menu Prices" and realizing the site isn’t updated – small errors can lead to confusion. Fixing AQWA issues usually means refining connections and double-checking input settings!

-

- You must be logged in to reply to this topic.

-

5274

-

1870

-

1403

-

1257

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.