TAGGED: combustion, fluent-dpm

-

-

December 3, 2025 at 12:53 pm

fanbo9802

SubscriberHello there,

I am modeling the Sydney Needle Spray Burner in Fluent with the EDC species transport model using a simplified ethanol mechanism, which could use in Chemkin to simulate 0D/1D flame.

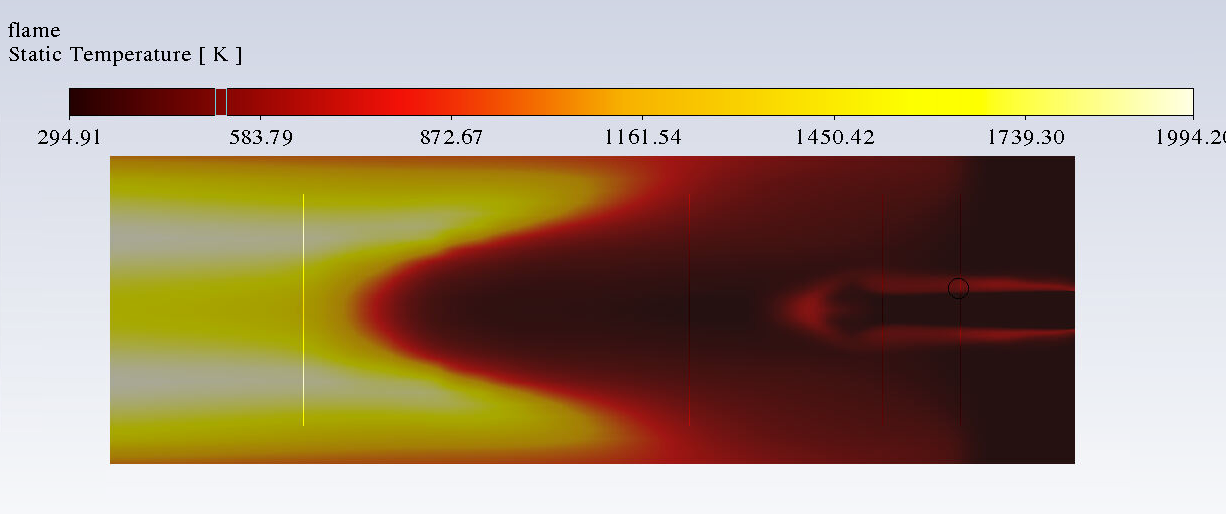

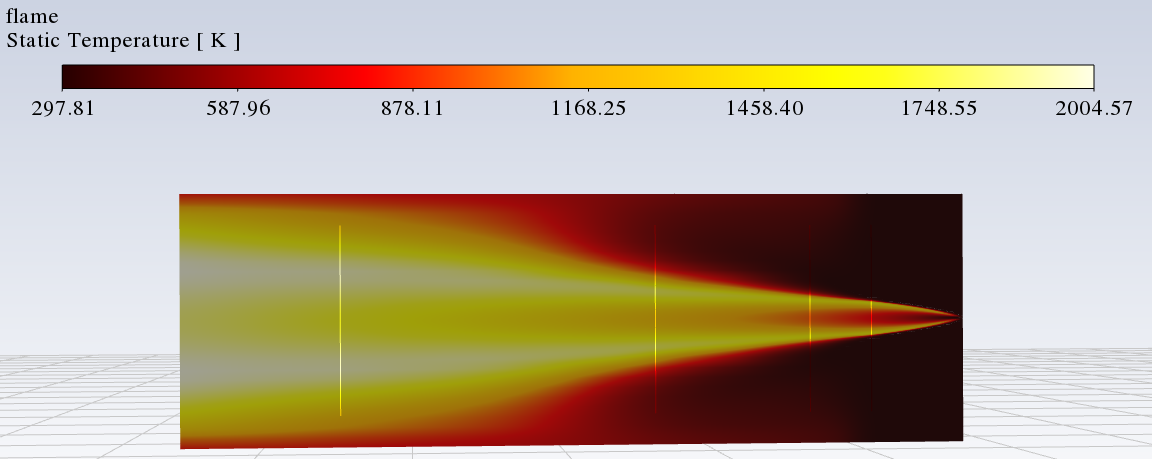

I got an EDM intial result, and switched model to EDC, the simulation does not float. But it also occurs the general problem, which extinguishing. Fig. 1 shows the temperature contour of EDM and EDC.

EDC result EDM result

I have tried to patch high tempture region, and mass fraction of products, also increased the volume fraction constant to 5, and time scale constant to 3, only few steps after patching, I can see the trend of ignition.

For turbulence modeling, the k-Omega SST is used. The time step is 1e-6 s.

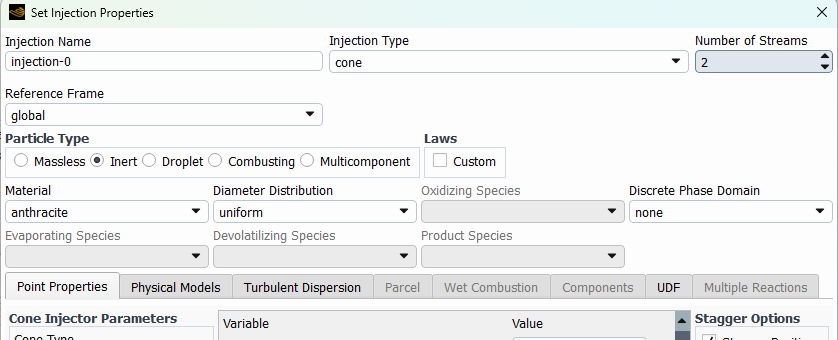

I also want to know, becasue of the grids number of injection face, the particles injected into domain is much more, which could reach at 30 million, its too much and increase the simulation costs.

-

December 4, 2025 at 4:34 pm

jcooper

Ansys EmployeeHi:

Even though the EDM and EDC models have similar rules when it comes to determining what conditions will allow ignition, there is not a perfect match between the two. This may affect flame position. For instance, it may be difficult to sustain ignition when switching between the two models, or you may get unexpected flame attachment, as shown in your pictures. The coefficients in the EDC model are tuned for natural gas, which is a very flammable fuel. If these are used for a less flammable fuel, combustion in some areas may be over-predicted.

The EDC model coefficients control the fine-scale residence time and volume fraction. Inappropriate EDC coefficient values can lead to either overly fast or slow reactions, affecting flame stabilization and lift. Decreasing the volume fraction constant may allow the flame to lift further from the burner and would be a good adjustment to try if you want the EDC flame to lift. Using the Partially Stirred Reactor (PaSR) option has also improved predictions in some cases. It may also be useful to refine the mesh close to the fuel injection point, so that the turbulence is more resolved, this will help in improving the flame position because the underlying flow field is better-predicted.

I am not sure what you mean by your last question on particles. If you are using one of the injectors, such as conical injection, you can control the number of particles injected by setting the number of streams.

Regards,

Judy

-

January 18, 2026 at 2:31 pm

fanbo9802

SubscriberHi, jcooper.

Thanks for your help, I noticed you mentioned PaSR option, is it the same as PaSR model. And I didn't find that option. I only read how to active the TFM with LES simulation through user mannual.

On the other hand, should I still increase the time scale constant?

Regards,

Bo

-

-

January 19, 2026 at 8:03 pm

jcooper

Ansys EmployeeHi:

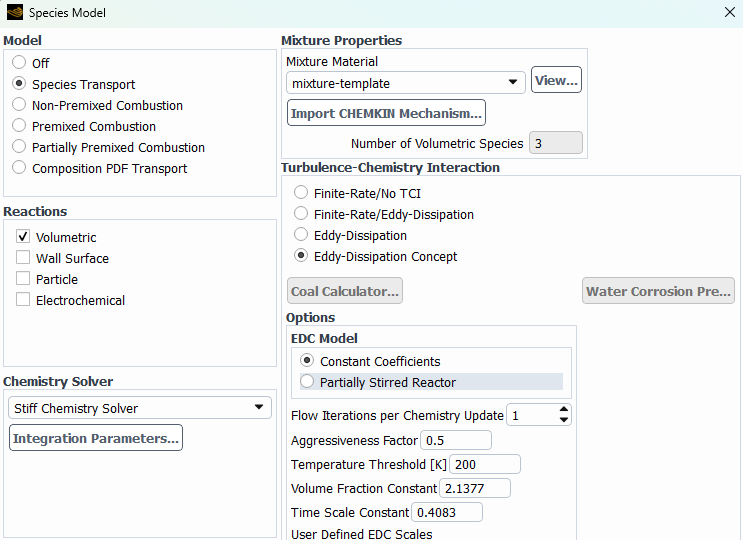

The Partially Stirred Reactor (PaSR for short) option is available for the EDC model here:

This changes the results of the chemistry. The PaSR model introduces a different definition for the reacting volume fraction and the time scale, making these parameters dependent on local flow and chemistry variables, unlike the standard EDC model which uses fixed constants. Switching to the PaSR option can result in faster reaction rates and improved ignition prediction in cases where the standard EDC fails to ignite or gives inaccurate results. It may be a good option if you are unsure how to set the timescale. Ethanol combustion is also somewhat bit different from methane combustion, which is what the EDC model is tuned for.

-

- 您必须登录才能回复此主题。

- Application of EDC occurs flame extinguishing

- 用EDC计算发现燃料不能顺利喷出

- 热仿真计算收敛

- Must EDC model need an initial flow field?

- Compile the UDF code and apply it to the DPM.

- Please help me check if there are any issues with the UDF.

- Negative droplet growth rate in Fluent wet steam model

- Difficulty in Complex Source Term Linearization

-

4934

-

1638

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.