-

-

November 22, 2025 at 2:10 pm

Ikram.MARZOUKI

SubscriberHi everyone,

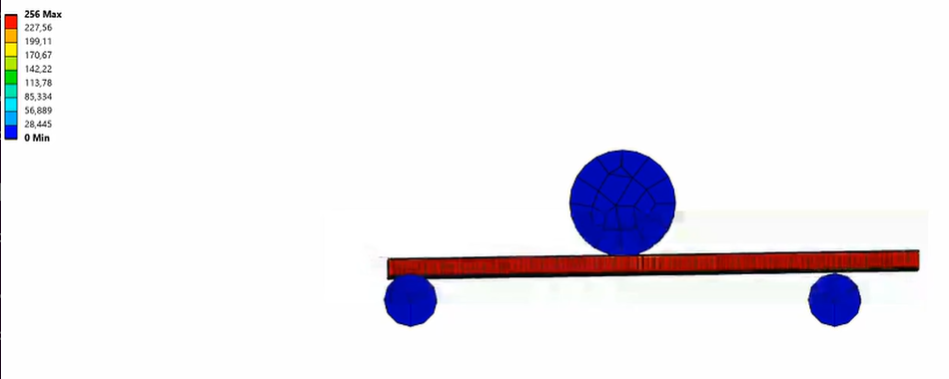

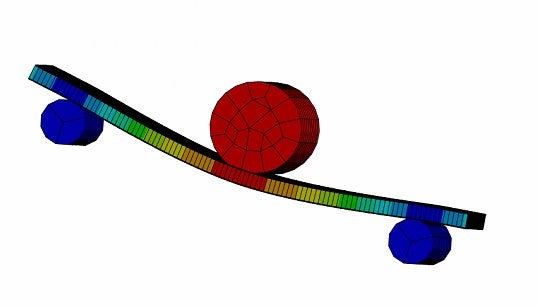

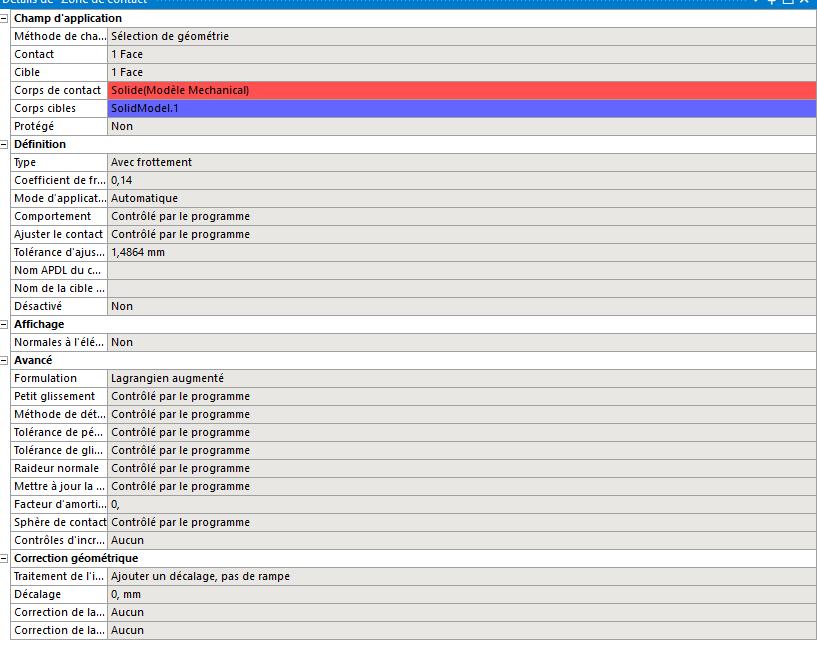

Here’s what I’ve observed in the simulation:I am testing a sandwich panel modeled with solid elements (SOLID) in a 3-point bending setup. The supports are cylinders, and I applied Remote Displacement to impose their translation.

When I set the contact between the cylinders and the sandwich as “totally bonded”, the simulation works even for relatively large displacements (e.g., 10 mm).

However, when I switch to contact with friction, the simulation only converges for small displacements. Beyond about 8 mm, it diverges.

I have added photos showing:

the case when the simulation diverges

the case when it converges

how I defined the contacts

Could someone advise what parameters I should modify to make the simulation converge for larger displacements with contact and friction?

-

November 24, 2025 at 10:17 am

ErKo

Ansys EmployeeHello

For this I recommend using 1/4 symmetry (as used here in this paper: Modeling Flexural Failure in Carbon-Fiber-Reinforced Polymer Composites) – as it is unstable.

Then when that is done, look on maximum substeps and general nonlinear convergence (say adjust to touch, normal stiffness,etc.):

https://www.youtube.com/watch?v=O-qTAiE8Kdo&msockid=8b77ec91c91e11f0a1f421c682991185

https://www.youtube.com/watch?v=sZf5p_evqOkFew videos out there that should help.

All the bestErik

-

- You must be logged in to reply to this topic.

- Free Faces in 3D CFD for formula student car

- LS dyna download error

- Use the CDF results for FEM analysis

- LS-dyna student version installation

- Divergence in 3-Point Bending Test with Contact + Friction

- Automating Sandwich Thickness/Gap in 3-Point Bending Workflow

- CFD tests with Discovery

- Tress structural´s simulation using carbon fiber tubes

- E-Racing Bergamo | Chassi’s torsional deformation

-

4934

-

1638

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.