TAGGED: cfd-dem

-

-

January 26, 2025 at 3:27 pm

z.sang

SubscriberDear Sir,

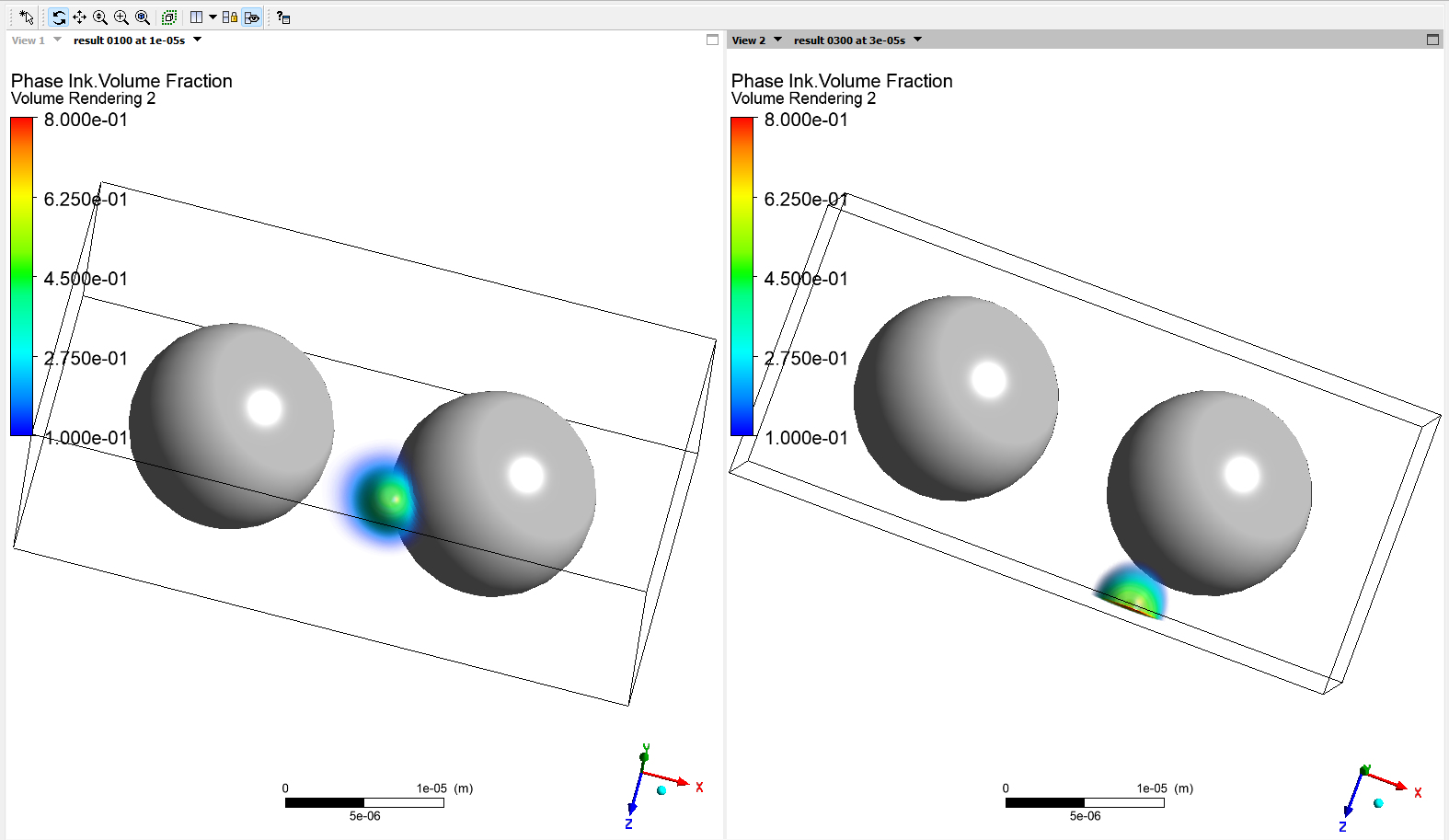

I am simulating liquid bridge force by coupling Ansys fluent and Rocky in a semi-resolved way. In my simulation, two spherical particles are deposited and a liquid droplet is placed between two particles. The droplet is tangential to two spheres. I would expect the liquid draw the particles inwards.

However, although the droplet is totally equally tangential to two spheres, it always first contacts one sphere and move with the sphere outwards. In the end, it transforms from the sphere to wall, as shown in the following picture.

I think the problem is due to the unstable contact between the droplet and the spheres. I would like to build a cell region with the shape of a cylinder with meniscus ends instead of a spherical droplet. Then, the initial point contact can be transformed to surface contact. However, I didn't find a way to build this irregular shape region. Could anyone please give me any advice?

I have also tried other methods, but they all didn't work. Could anyone give some other ideas to modify the model?

-

January 27, 2025 at 11:52 am

Rob

Forum ModeratorHow are you modelling the spheres in Fluent?

-

January 27, 2025 at 12:32 pm

z.sang

SubscriberThank you very much for your reply.

According to the 'Rocky CFD coupling Technical Manual', the modelling about the particles(spheres) was done completely in Ansys Rocky and use the semi-resolved CFD coupling function. In Fluent, I only modelled fluid phase, including air and liquid droplet.

-

-

January 27, 2025 at 1:31 pm

Rob

Forum ModeratorDon't think it's supposed to work like that. The liquid bridge is a contact model. How did you model the droplets in Fluent?

-

January 27, 2025 at 2:06 pm

z.sang

SubscriberIn fluent, multiphase model of Eulerian model is used, and the number of Eulerian Phases is 2, including air and liquid. For phase interaction, the drag coefficient is calculated by schiller-naumann law and the surface tension coefficient is set to a constant value. Besides, continuum surface force model is employed. The viscous model is laminar.

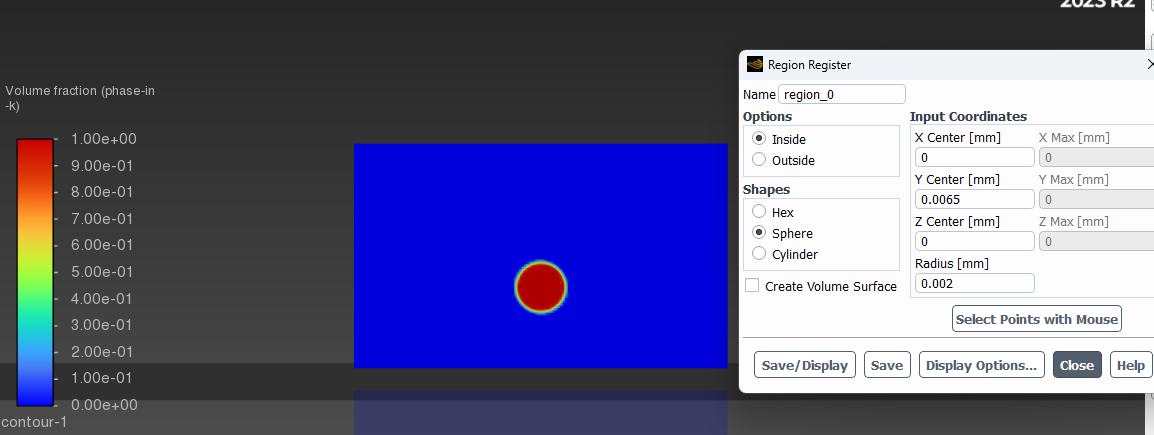

Then I set a cell region register with a sphere shape as the droplet and patch the volume fraction of liquid phase as 1. The position of this droplet is just tangential to both spheres.

Generally, there is no gravity and no wall adhesion, because I would like only to investigate the interaction between droplet and particles and prove the feasibility of coupling method.

Also, the mesh size is 0.2µm, the sphere diameter is 13µm, and the droplet diameter is 4 µm.

-

-

January 27, 2025 at 2:54 pm

Rob

Forum ModeratorThe Eulerian droplet phase had a diameter of 4microns or the patch was 4microns?

-

January 27, 2025 at 3:00 pm

-

-

January 27, 2025 at 3:26 pm

z.sang

SubscriberHello Rob, I looked through again my results. When I added a isosurface to my droplet, I found the droplet has infiltrated into the sphere instead of forming a contact angle on the sphere surface.

I am not sure whether this phenomenon indicates the coupling between Ansys Fluent and Rocky failed and thus droplet was not affected by the particle, leading to an inaccurate numerical prediction, although it showed the solution was converged. Would you think further refinement of mesh would be one of the solution?

-

January 27, 2025 at 3:32 pm

Rob

Forum ModeratorThe Rocky coupling works via a source/porous media method in that there isn't a "wall" surface for the flow to hit. You may need to review moving mesh and VOF in Fluent, which isn't going to be simple or computationally cheap. At 4microns you're also going to be moving beyond where some of the models are fully valid without correction terms (which you'd need to figure out).

-

January 27, 2025 at 3:53 pm

z.sang

SubscriberI only read from the manual and learned that Rocky coupling is based on the immersed boundary approach. there is no 'wall' surface, so do you mean that by semi-resolved CFD coupling method it won't be possible to simulate the capillary effect?

-

January 27, 2025 at 3:58 pm

Rob

Forum ModeratorCorrect. It's a bulk model rather than a way of modelling a couple of particles in detail. The Rocky team are aware of the thread, but will only comment if they think I've missed something.

-

January 27, 2025 at 4:18 pm

z.sang

SubscriberThank you very much for your reply.

Although honestly spreaking it is disappointing to hear that, I really appreciate your advice. Unfortunately, only fluent is not enough for my situation, because particle dynamics is very important in my case. I will try to think about other methods.

-

January 27, 2025 at 5:08 pm

Rob

Forum ModeratorAre you looking at two particles or many? The best choice of model and solver is based on the needs of the simulation. I use pretty much anything from pencil & paper up to 200 nodes parallel Fluent coupled to Rocky on GPU depending on what best suits the application.

-

January 27, 2025 at 6:03 pm

z.sang

SubscriberI can understand. What I am trying is actually the particle rearrangement due to the effect of liquid droplet deposition. Therefore, the fluid flow and particle dynamics are both involved. I know this target requires pretty high computational cost, and thus I simplified the model to a two sphere model.

-

-

January 28, 2025 at 11:57 am

Rob

Forum ModeratorOK, thanks. For two particles, and a single droplet you'll need to model using "real" geometry for the particles and VOF for the droplet. For a bulk model with many particles and droplets the Rocky liquid bridge models etc would be used instead; possibly with coupling to Fluent depending on what's going on.

-

- You must be logged in to reply to this topic.

- How do I get my hands on Ansys Rocky DEM

- Non-Intersected faces found for matching interface periodic-walls

- Unburnt Hydrocarbons contour in ANSYS FORTE for sector mesh

- Help: About the expression of turbulent viscosity in Realizable k-e model

- Mass Conservation Issue in Methane Pyrolysis Shock Tube Simulation

- Facing trouble regarding setting up boundary conditions for SOEC Modeling

- Script Error

- convergence issue for transonic flow

- RIBBON WINDOW DISAPPEARED

- Running ANSYS Fluent on a HPC Cluster

-

1772

-

635

-

599

-

591

-

366

© 2025 Copyright ANSYS, Inc. All rights reserved.