-

-

October 26, 2023 at 10:16 am

karim.el-ghamrawy

SubscriberHello,

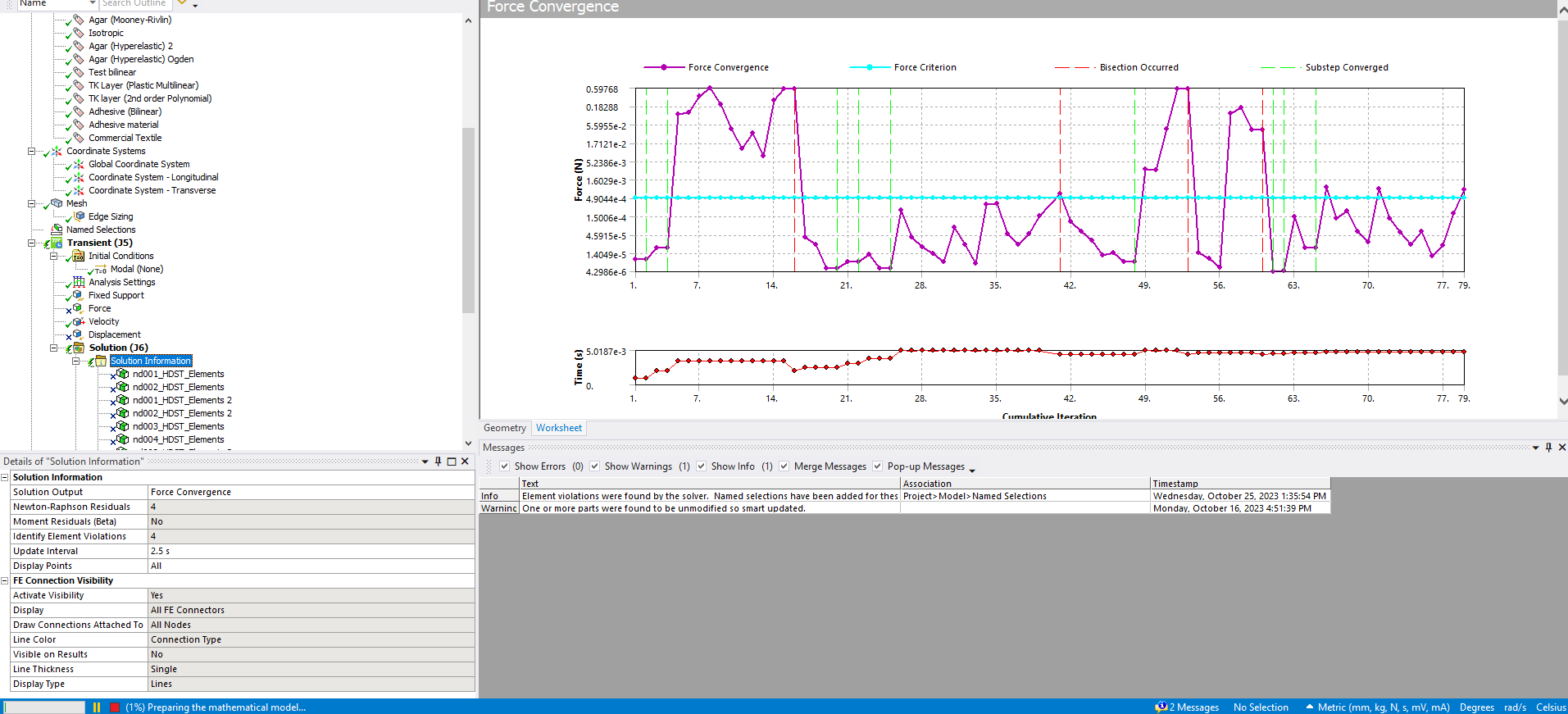

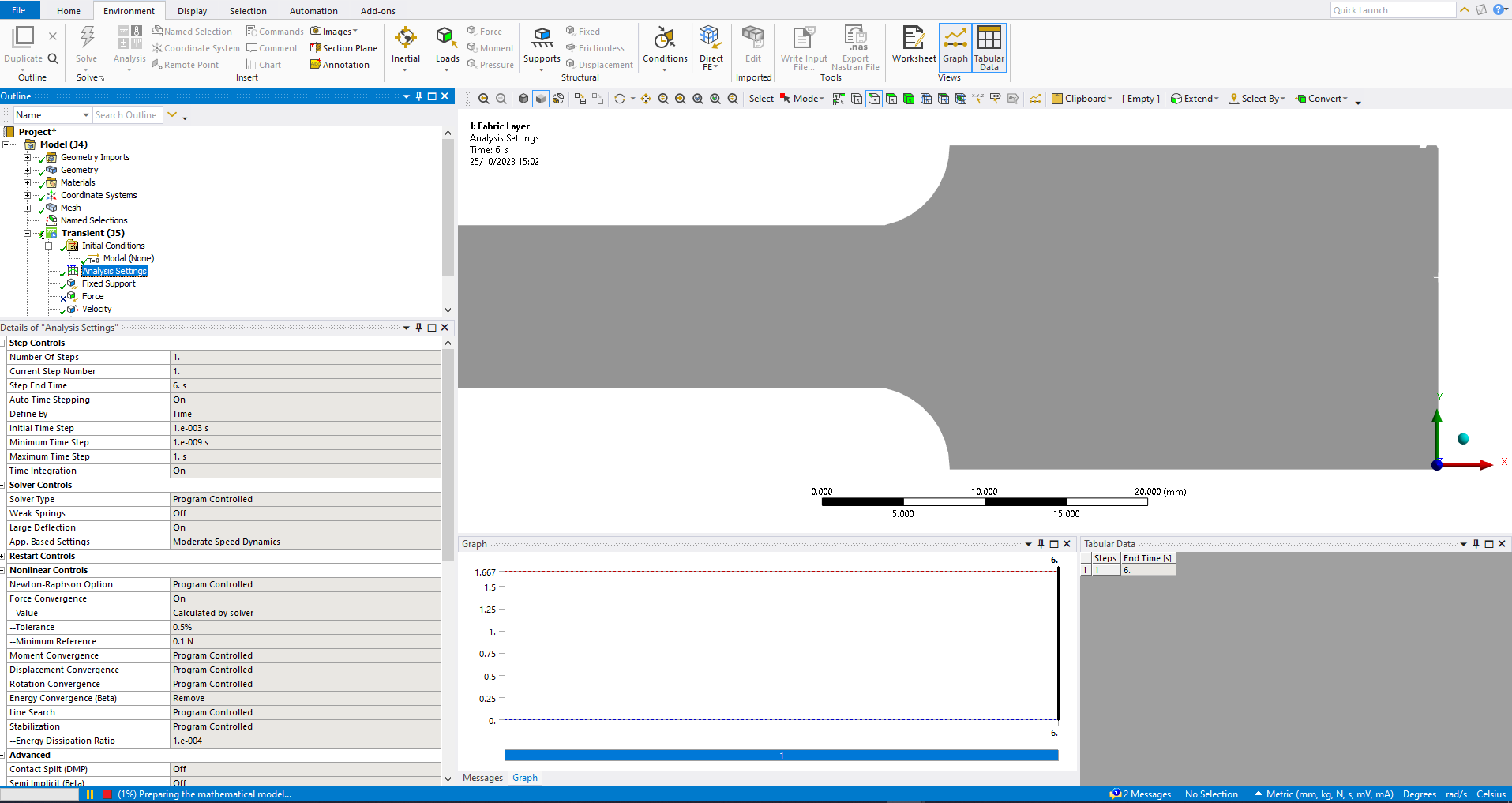

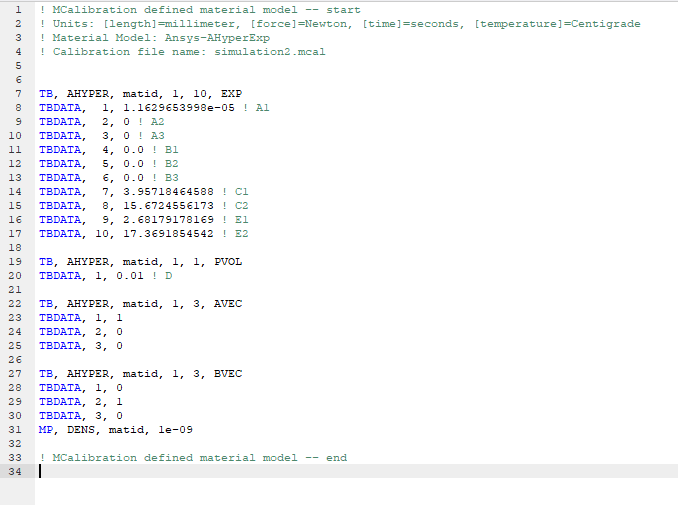

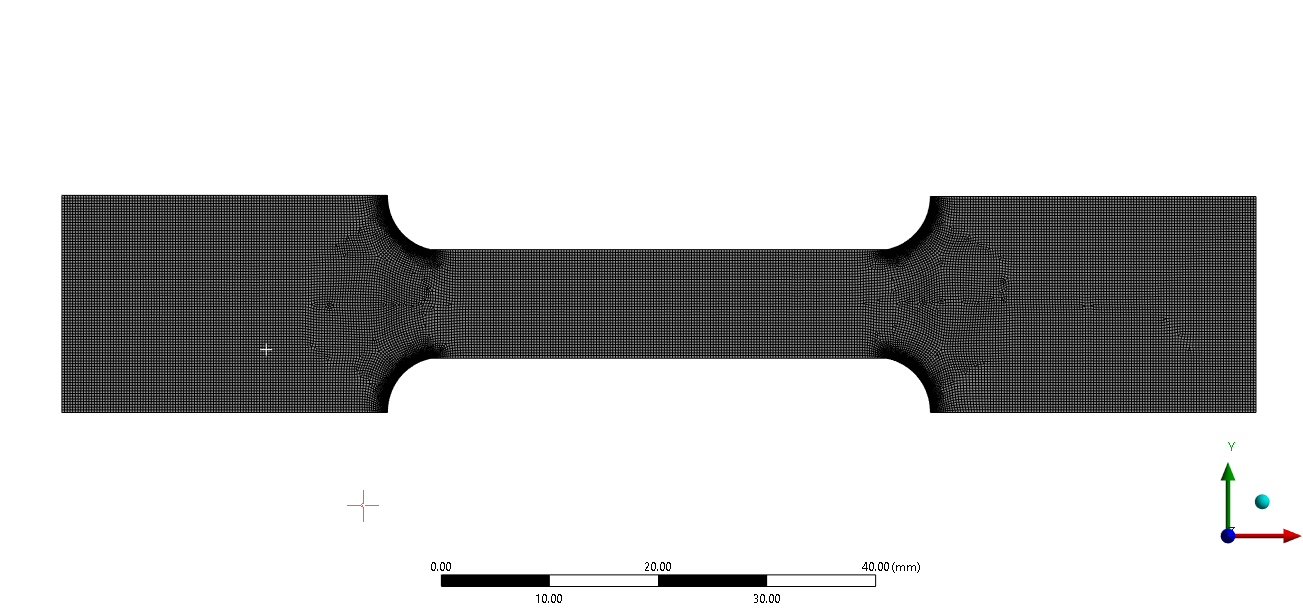

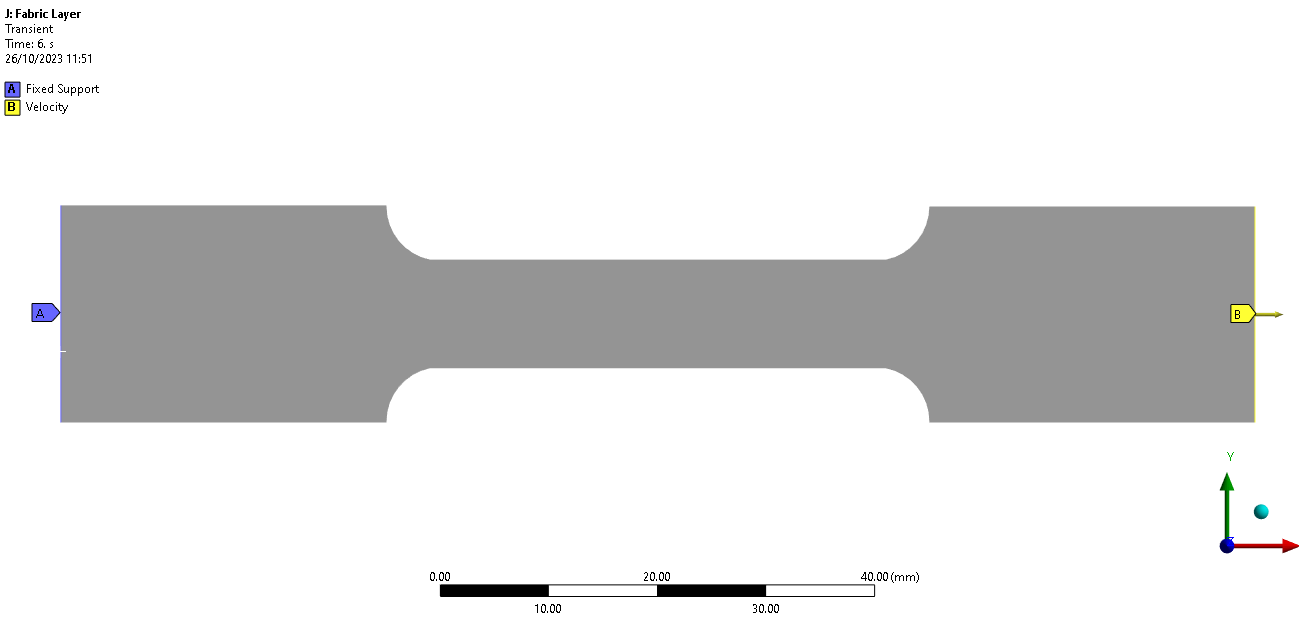

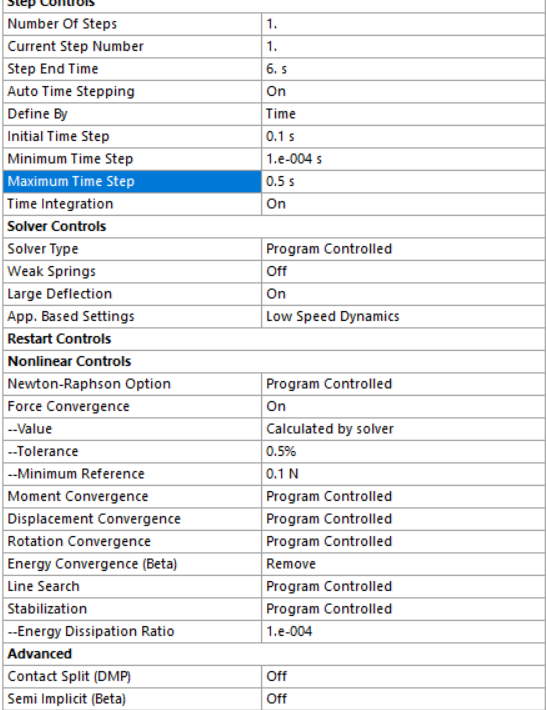

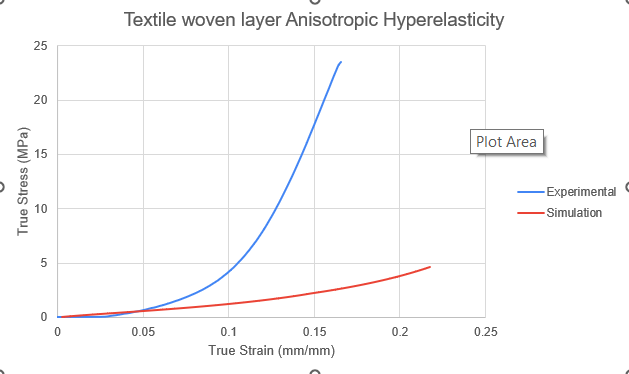

I am trying to model a thin layer of a woven fabric. I am interested in simulating a tensile test to match experimental data. After a bit of research in the literature, I understood that the community uses an anisotropic Hyperelastic material model for these kinds of problems. I went to MCalibration and calibrated a material model based on the experimental data in the Warp and Weft directions and uploaded the material card in Ansys. I am using shell elements as the thickness of the layer is 0.36mm and with large deflection set to on.

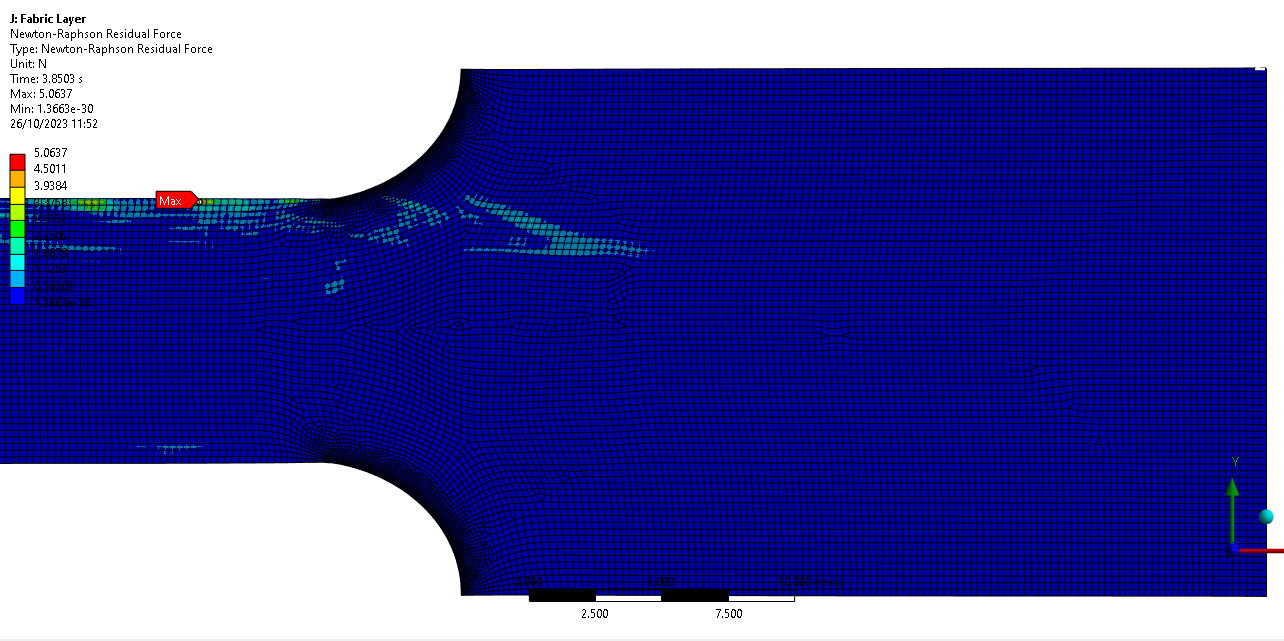

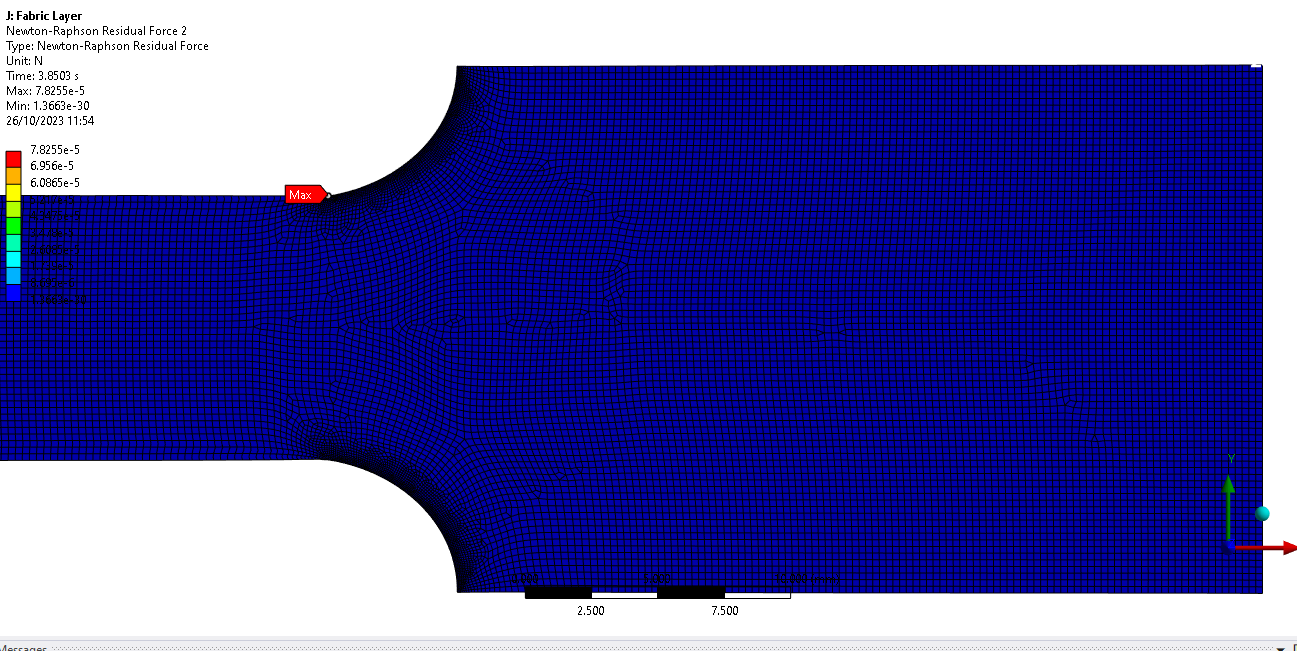

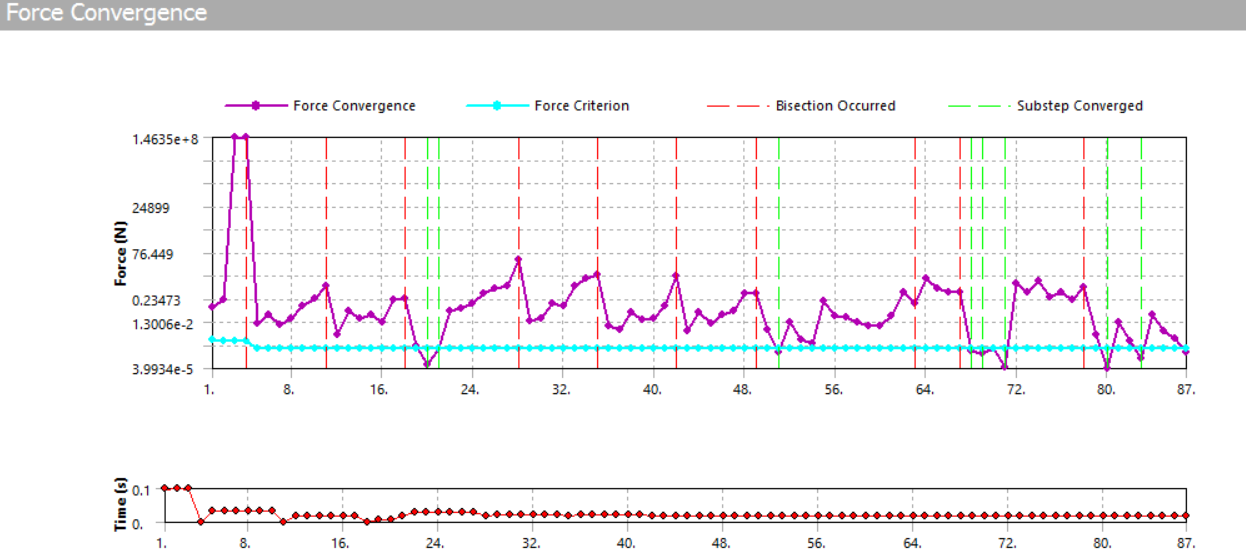

I ran a transient simulation for a tensile test on a dogbone. The simulation failed to converge. I am attaching some of the settings I used. I tried applying a displacement BC and a velocity BC but it did not make any difference in the convergence. I tried to refine the mesh, I tried to reduce the time step, no success. I tried to simulate the problem with a normal hyperelastic (Ogden) material model from Ansys library, still I am failing to converge.

I am attaching some photos that would help clarify the issues.

Could someone please guide me on what to do or what might be the problem?

-

October 26, 2023 at 10:29 am

peteroznewman

SubscriberThe velocity used in a tensile testing machine is very, very, low. That means you should be using Static Structural instead of Transient Structural.

Changing to Static Structural won't fix the error that prevents this model from converging. There is still much work to do. I see an Element Distortion error. Please reply with an image of the mesh and show the boundary conditions you are using. When you get the element violation, show which elements those are. We need to see where those elements are.

-

October 26, 2023 at 11:00 am

karim.el-ghamrawy

SubscriberThank you very much for your prompt response. The velocity of the machine is indeed slow (1.6667mm/s). I understand that it should be static, however, I chose a transient simulation for a faster application later on after I validate the model using the experimental data. So I wanted to setup one model. I played a bit with the App. Based Setting in the Solver Controls. I set it to quasi-static and also to low speed dynamics, but without success.

I am attaching the photos as requested.

-

October 26, 2023 at 8:41 pm

peteroznewman

SubscriberI suggest you remove the mesh refinement controls on the arcs. I also recommend you set the Element Order to Linear before you remesh. Then try solving with a uniform linear element size.

Under Analysis Settings, it is important to force the solver to use many small step and prevent the solver from using larger steps. Automatic Time Stepping should be On. Please show your settings.

-

October 27, 2023 at 3:25 pm

karim.el-ghamrawy

SubscriberHi again,

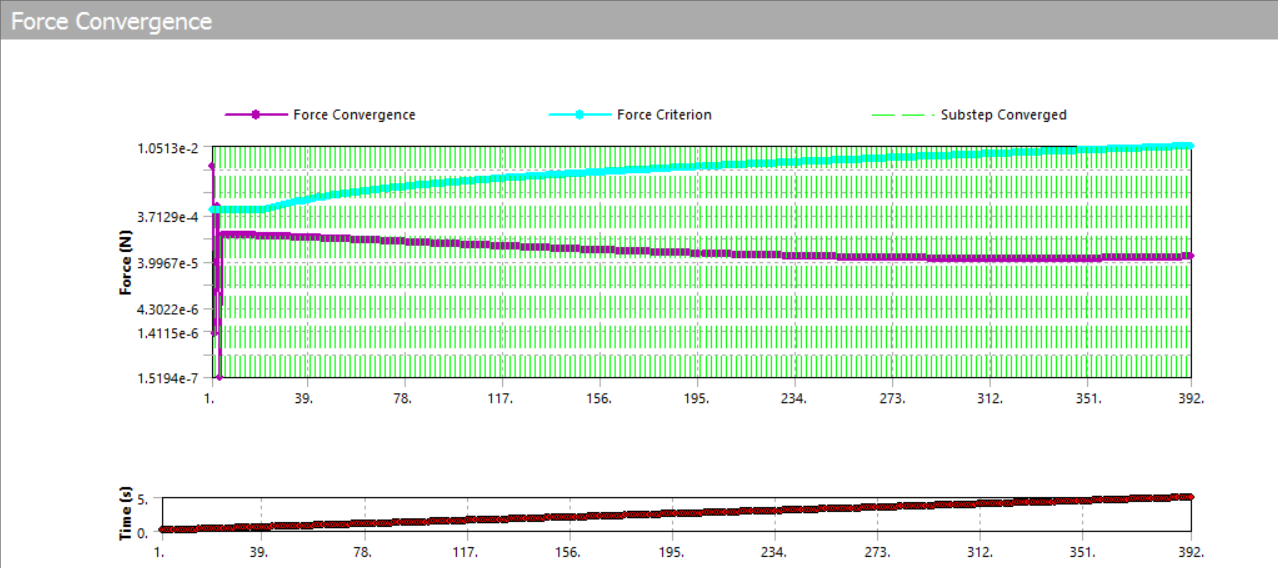

Thank you for your response. I tried with linear elements without changing the mesh and it did not converge. I then removed the sizing effect and it converged! I am very curious to know why the sizing affects convergence?

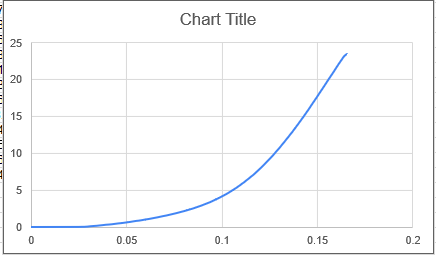

The results, however, are off. I am attaching some screenshots to demonstrate that. It seems the material behaviour is captured up until a point where the material starts to behave exponentially. Any suggestions why is that happening?

Note that I am inputting the engineering strains and stresses to calibrate the material model. ANSYS outputs true stresses and strains, so I converted my experimental data to true stresses and strains for postprocessing.

Thanks again for the support.

-

October 27, 2023 at 3:59 pm

karim.el-ghamrawy

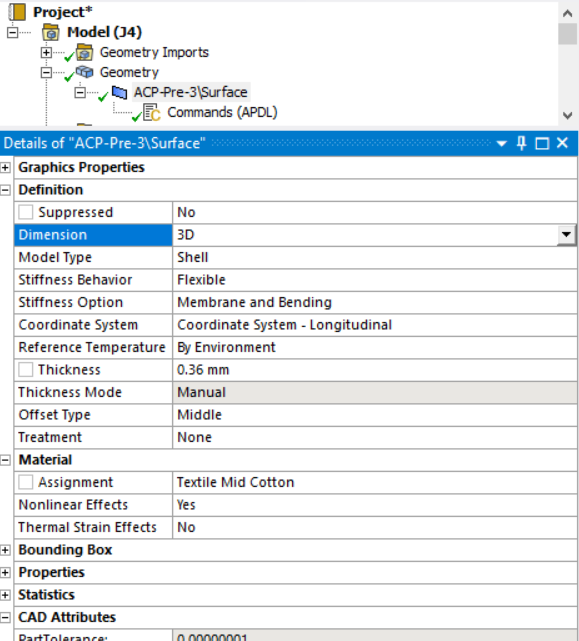

SubscriberSorry, a follow up comment. My simulation is a standalone at the moment, but I am planning to make it part of the ACP prepost.

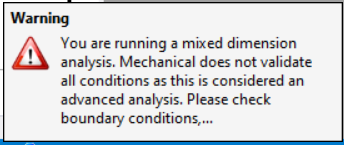

A general question, I am only converging now when the geometry is set to 2D plane stress. Otherwise I do not converge. What I understand is that ACP analysis type has to be 3D, is that the case? If I convert the simulation I showed in this thread to 3D I do not converge. When I set it to 2D plane stress, I get the attached warning message. I am attaching additional screenshots for demonstration.

2D plane stress warning:

-

October 31, 2023 at 10:49 am

karim.el-ghamrawy

Subscriber -

October 31, 2023 at 10:50 am

karim.el-ghamrawy

SubscriberHi,

I am just following up with my previous post.

Thank you

-

October 31, 2023 at 6:17 pm

peteroznewman

SubscriberIt looks like your model has a fixed support on the left side and a force on the right side which worked in 2D but fails in 3D.

I suggest you add a Z = 0 constraint on the right edge where the force is applied. This will help to stabilize the 3D solution. You might need a Y = 0 constraint also.

-

October 31, 2023 at 10:23 pm

karim.el-ghamrawy

SubscriberHi Peter,

Thank you again for your response.

Unfortunately, it did not improve the convergence. I tried both to constrain the displacement in Z and then in Z and Y together.

Any other recommendation? I've been wrestling with this for a couple of weeks now with no success.

Your help is much appreciated

Thank you!

-

November 2, 2023 at 6:26 pm

karim.el-ghamrawy

SubscriberDear Peter,

I am just following up with the post. Your help is very much appreciated.

Thank you

-

- The topic ‘Woven fabric modelling’ is closed to new replies.

-

4853

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.