-

-

November 10, 2024 at 9:48 pm

mmh.rakin

SubscriberPlease recommend me the steps to follow in ansys mechanical, for a cylindrical pressure vessel,1. How to find the elastic limit load2. How to find the elastic-plastic limit load -

November 10, 2024 at 10:55 pm

peteroznewman

SubscriberThere may be a Pressure Vessel Design Code that you can follow in your country. I don’t know about that. Below is what I would do. Static Structural models start out with a default Structural Steel material. I will show results for that, which has a Tensile Yield Strength of 250 MPa. You may want to create a specific material, but you will need to add a plasticity material model. Let’s leave that aside for now.

First off, add a cap to balance the forces on the pressure vessel. Open SpaceClaim to do this.

Since the geometry and loads are axisymmetric, use the X-Y plane to slice the geometry in half and delete the +Z piece, slice that half with the Y-Z plane and delete the -X quarter. Click on the cut face in the X-Y plane and type Ctrl-C, Ctrl-V to create a surface, then delete the last solid body. This is the geometry you will mesh. Save the SpaceClaim file.

Open Workbench and drag out a Static Structural analysis onto the Project schematic. Click on the Geometry cell and import the SpaceClaim file. Right click on the Geometry cell, select Properties. In the Window on the right, set the Analysis Type to 2D.

Double click on the Model cell to start Mechanical. After the geometry loads, click on Geometry in the Outline and in the Details, set the 2D Behavior to Axisymmetric.

The edges on the Y axis are automatically going to stay there, but it does no harm add a Displacement support of X = 0.

The vertex on the bottom of the vessel is on the Y axis, add a Displacement of Y = 0. This is the only support needed to prevent rigid body motion due to this being an axisymmetric analysis. The vessel is free to expand in any direction under the pressure load.

Add a 1 MPa Pressure load to the edges on the inside of the vessel.

Mesh the face so that you have about 6 or more quadratic elements through the thickness.

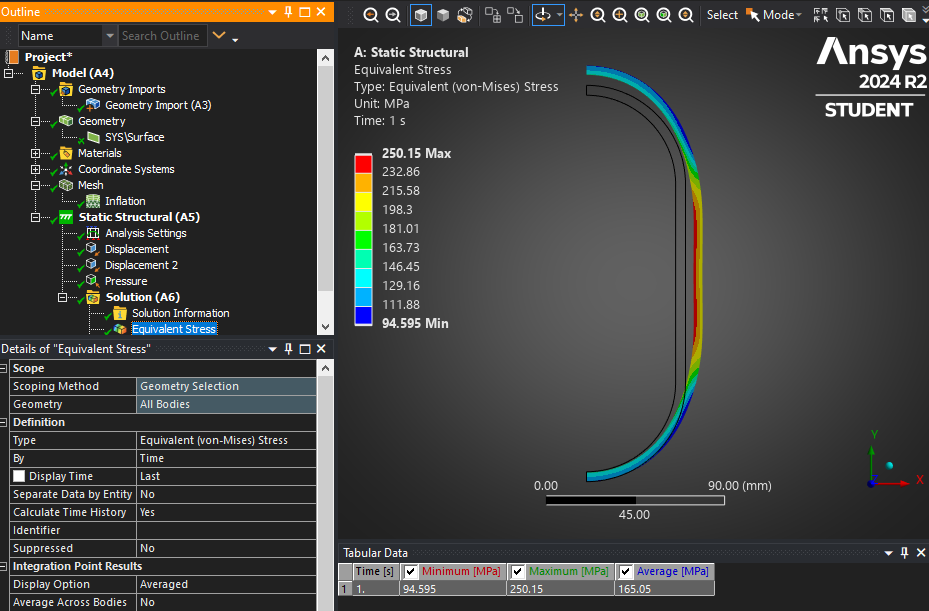

Solve this model with the defaults to get the linear solution, which is a good place to get an initial result for the first question. Add an Equivalent Stress result. In my model, I get a von-Mises stress of 9.2 MPa.

Since this is a linear result, simply calculate the Elastic Limit Load as 250/9.2 = 27.17 MPa, with no Factor of Safety. You can type that number into the pressure and solve again to check.

I will answer the fully plastic question in another reply.

-

November 11, 2024 at 9:30 am

mmh.rakin

SubscriberThank you so much. Is there any sophisticated way in ansys to make first yield point graph? Also, please guide me about plastic limit.

-

November 11, 2024 at 3:47 pm

peteroznewman

SubscriberThe yield point graph would not be very interesting. Plot pressure in MPa on the x axis and maximum stress in MPa on the y axis, there would be a straight line from (0, 0) to (27.17, 250).

Here is my answer to question 2.

-

- You must be logged in to reply to this topic.

-

3432

-

1057

-

1051

-

896

-

892

© 2025 Copyright ANSYS, Inc. All rights reserved.