-

-

February 10, 2023 at 6:16 pm

ali.afrouzian

SubscriberI'm going to couple Jmat pro with Ansys.

I'm going to use Jmat pro to capture the physical properties during metal additive manufacturing.

I was wondering if any of you guys have done that.

Please reply if you have any information.

-

February 13, 2023 at 8:32 pm

Reno Genest

Ansys EmployeeHello Ali,

I am not familiar with JmatPro. I did a quick search and it seems there is an export to LS-DYNA from JmatPro. What is the material output? What is the LS-DYNA *MAT_ card written by JmatPro?

Are you trying to do welding simulation? JmatPro has been used with LS-DYNA for welding:

https://www.dynalook.com/conferences/16th-international-ls-dyna-conference/metal-forming-t8-2/t8-2-a-metal-forming-138.pdf

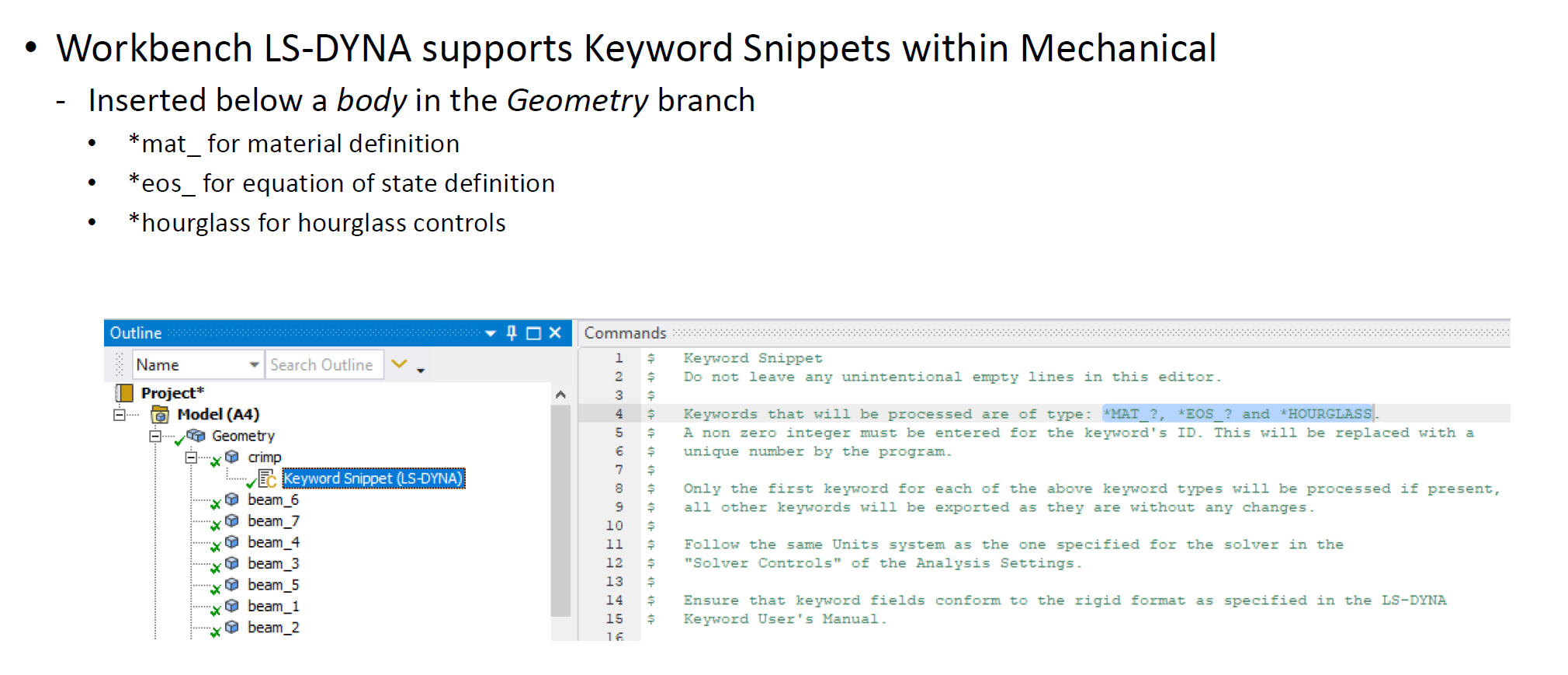

If JmatPro exports the correct *MAT_ material card, then you can import this *MAT_ card in Ansys WB LS-DYNA (Mechanical) using a command snippet under the appropriate body:

Let me know if this helps or not.

Reno.

-

February 14, 2023 at 5:32 am

ali.afrouzian

SubscriberHi Reno,

Thanks for the response.

Yes, I'm going to use it for my metal additive manufacturing work which is cyclic melting and solidification.

-

February 14, 2023 at 4:52 pm

Reno Genest

Ansys EmployeeHello Ali,

Ok, let me know how it goes. You can also try to reach out to JmatPro support for help:

https://www.sentesoftware.co.uk/agents-3509

Reno.

-

February 16, 2023 at 3:17 am

Reno Genest

Ansys EmployeeHello Ali,

I contacted JMatPro® support and they replied the following:

"The export from JMatPro® to LS-DYNA is for welding simulations and based on the CWM model. It was created after a request by an existing customer and is limited to Al alloys and steels.

The next major version of JMatPro® will include an export to Ansys Workbench for all material types considered.

It is always possible for the end-user to cut and paste the calculated properties from JMatPro® to whatever format required".

Here is an example of material output from JMatPro® to LS-DYNA:

"*KEYWORD

$---+----1----+----2----+----3----+----4----+----5----+----6----+----7----+----8

$ ALLOY_ID_WT% Al88.87Cr0.23Cu1.6Fe0.5Mg2.5Mn0.3Si0.4Zn5.6

$ ALLOY_ID_AT% Al93.03Cr0.125Cu0.711Fe0.253Mg2.905Mn0.154Si0.402Zn2.419

$ Alloy calculated with JMatPro

$ JMatPro VERSION 14.0

$ MATERIAL TYPE = Aluminium Alloy

$ SubType = HT

$ Alloy Type = Wrought

$ Heat Treatment = T5

$ Quench temp (K) = 773.15

$ Ageing temp (K) = 423.15

$ Grain Size = 50 microns

$ Additional heat treat = None

$ Constant Testing Time = 0.0 h

$ Strain rate: 0.001 0.01/s)

$---+----1----+----2----+----3----+----4----+----5----+----6----+----7----+----8

*MAT_CWM_TITLE

Material Description

$# mid ro lcem lcpr lcsy lchr lcat beta

1 2.807E-6 10001 10002 -10003 10005 1.0

$# tastart taend tlstart tlend eghost pghost aghost

460.0 630.0 -1000000 -100000.0 0.49

$---+----1----+----2----+----3----+----4----+----5----+----6----+----7----+----8

*MAT_THERMAL_ISOTROPIC_TD_LC_TITLE

Material Description

$# tmid tro tgrlc tgmult

1 2.807E-6

$# hclc tclc

10006 10007

$---+----1----+----2----+----3----+----4----+----5----+----6----+----7----+----8

*DEFINE_CURVE_TITLE

Young's modulus

$# lcid sidr sfa sfo offa offo dattyp lcint

10001 1.0 1.0

$# a1 o1

25.0 6.99734E1

40.0 6.94673E1

60.0 6.87761E1

80.0 6.80661E1

100.0 6.73371E1"Reno.

-

- The topic ‘Jmat pro and Ansys’ is closed to new replies.

-

3597

-

1208

-

1092

-

1068

-

952

© 2025 Copyright ANSYS, Inc. All rights reserved.