-

-

August 5, 2025 at 5:56 pm

SolutionParticipant

SolutionParticipantWhat’s New in Ansys Rocky 2025 R2

Ansys Rocky™ particle dynamics simulation software fosters particle simulation beyond traditional DEM and in the 2025 R2 Rocky applications bring advancements that will open new possibilities for your projects.

With powerful Multiphysics capabilities, enhanced Performance and greater Usability to elevate your particle simulation experience, Ansys Rocky 2025 R2 focuses on improved solver efficiency, extended DEM capabilities, and smarter integrations, empowering engineers to solve complex particle dynamics problems faster and with greater accuracy.

Explore what’s new in Ansys Rocky 2025 R2 and discover how these enhancements can help you accelerate innovation in your applications.

DEM Simulation Improvements

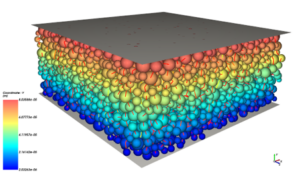

Deformable Particles

Committed to always bringing the best resources for DEM simulations, this new release brings the particles deformation beta feature, which enables particle large deformation through an FEM-inspired element deformation approach.

In this simulation you can see a Tablet Compaction simulation using the deformable feature.

The deformable resource is ideal for applications involving significant elastic and plastic deformation of particles, such as calendering in battery manufacturing and tablet compaction in pharmaceuticals. In addition to being compatible with the Discrete Breakage model already present in Ansys Rocky software.

In this simulation you can also see a Calendering Process simulation using the deformable feature.

Simulating deformable particles is essential for accurately modeling real-world materials where particles undergo shape changes under stress, impact, or compression. Unlike rigid particles, deformable particles can absorb and distribute energy differently, making their simulation critical in processes involving soft materials, agglomerates, or high-impact interactions.

With deformable particle modeling, engineers can:

- Analyze particle compaction, breakage, or shape evolution;

- Predict flow behavior of soft or elastic materials;

- Improve accuracy in handling and processing simulations, such as in food, pharmaceuticals, and powders;

- Evaluate material performance under real-world operating conditions.

Edinburgh-Elasto-Plastic-Adhesion (EEPA)

This new release also brings the Edinburgh-Elasto-Plastic-Adhesion (EEPA) model which allows tensile forces to develop, and non-linear force-displacement behavior in compression.

The Edinburgh-Elasto-Plastic-Adhesion model is very useful for industrial processes in which particulate materials are subjected to compression, resulting in an increased adhesion effect between particles due to contact area enlargement caused by plastic deformation. A typical case is the simulation of calendering processes on battery manufacturing.

Calendering process for battery manufacturing simulation

DEM Liquid Spray

Knowing that the DEM method offers a multitude of possibilities, this release adds to Rocky software capabilities the ability to model spray droplets using DEM and on top of that, gives you the ability to create a simple spray effect on spray droplets, spreading particles apart in a cone-like fashion, to represent a real spray pattern.

The DEM Liquid Spray is GPU-compatible and works by disabling contact detection for all particle groups set as spray particles.

CGM support for JKR Adhesion model

The inclusion of the JKR (Johnson-Kendall-Roberts) adhesion model in the Coarse-Grain Model (CGM) framework offers significant benefits for simulating particle behavior where adhesive forces play a critical role. By combining coarse-graining techniques with advanced adhesion physics, simulations become both more realistic and computationally efficient.

Key advantages include:

- Accurate Representation of Adhesive Forces: The JKR model accounts for surface energy and deformation at contact points, enabling realistic simulation of cohesive particle behavior in CGM systems.

- Improved Modeling of Fine and Sticky Materials: Even with coarser representations, the physics of sticking, agglomeration, and clustering are better captured, essential for powders, pharmaceuticals, and food industries.

- Better Scalability with Realistic Interactions: CGM reduces computational load, and with JKR, it still preserves essential microscale adhesion effects—allowing larger-scale systems to be simulated without sacrificing accuracy.

- Enhanced Process Insight: Simulations involving compaction, coating, granulation, or segregation become more predictive, supporting better process design and optimization.

Material Storage

Material Storage is a new ready-to-use script, for particle properties management which makes it possible to import, save, share and remove materials using a local or Ansys Granta® database.

Key advantages include:

- Reuse calibrated materials;

- Save new materials;

- Fix incorrect or outdated entries;

- Material data preview and editing;

- Share Custom Data Base;

- Supports custom STL.

MULTIPHYSICS| Coupling

Semi-Resolved Thermal Support

This feature adds support for Heat Exchange between Particle and Fluid in Semi-Resolved coupled Rocky-Fluent simulations. There are two versions of the implementation: one supporting laminar flows and another supporting turbulent flows.

- Laminar Implementation: performs the standard linear interpolation between the particle surface conditions and the neighbor fluid cells to compute the temperature that will be imposed in the surface cells.

- Turbulent implementation: uses the turbulent temperature boundary layer equations, based on the turbulent quantities of the neighbor cell, to compute the turbulent heat flux in the particle surface. This heat flux is then used to compute the temperature to be imposed in the surface cell.

Heat Exchange support between Particle and Fluid in Semi-Resolved coupled Rocky-Fluent simulation.

2-Way Structural Coupling with DEM/SPH

With the 2-Way Structural Coupling (SPH-FEA) for Fluid-Structure Interaction (FSI) it is possible that Rocky software sends the SPH forces to Ansys Mechanical™ software, which calculates deformations and send the displacements back to a Rocky project.

This coupling allows both the fluid and the structure to influence each other dynamically during the simulation, which is essential for capturing real-world behaviors in engineering applications such as structural deformations caused by fluid forces and deformed structure influence in the fluid flow.

Suitable for applications like tank sloshing, hydroelasticity, wave impact on offshore structures, blood flow in arteries, fluid-structure interactions in manufacturing, and more.

For this DEM/SPH Mixing example, all the forces acting in the Mixer are sent to Mechanical, which calculates the deformation and sends back the incremental displacement to Rocky. Here, both the DEM/SPH behavior and the Mixer structural integration can be analyzed.

Watch the Ansys Rocky: 2-Way Structural Coupling with Mechanical on the YouTube.

Temperature Dependent Viscosity

The Temperature Variable Viscosity Module allows defining a temperature-dependent SPH viscosity. Users can specify the viscosity of the fluid as a function of temperature using a csv input file.

In the piston gallery simulation case, it is important to consider viscosity variability, with different temperatures.

Electromagnetic Coupling module enhancements

Ansys Rocky 2025 R2 also brings new enhancements for Electromagnetic simulations such as:

- It was implemented the field modulation. Four new models for field modulation were implemented: Sine, Square, Triangle, and Sawtooth;

- Any evaluated field property can be now modulated according to one of the available models;

- The possibility to enable static point clouds to represent transient phenomena.

EDS (Electrodynamic Screen) process, for solar panel cleaning.

Particles (dust) are removed by a custom electric force generated from a 3 static point clouds (Ansys Maxwell® software) and the modulation feature. This was implemented using Rocky Solver SDK.

Usability Enhancements

The latest updates in Ansys Rocky software bring significant usability enhancements designed to streamline workflows, reduce setup time, and improve overall user experience. These improvements empower both new and experienced users to work more efficiently and with greater confidence when performing particle simulation tasks.

Key usability enhancements include:

- New curves and properties for SPH: SPH Solver curves were created so users can have access to more information related to solver SPH iterations, while SPH Properties were created to improve post processing custom expressions capabilities;

- Variable Force Field: User loads a Time X Gravity table through a .csv file and gravity will change overtime according to what was defined in the user’s table. (available with the Variable Gravity Module);

- Point Cloud support for vectorial properties;

- Better performance when loading Properties during scripting;

- Coefficients used to calculate drag, lift, heat transfers, etc. are now exposed as particle properties;

- Oriented Volumetric Inlet;

- Users can now use the same Cube/Cylinder region to post process different data (e.g. Particles data, Geometries data, SPH data, etc.).

Rocky Automation & Customization Enhancements

More features related to automation and customization were added in this release such as:

- Solver SDK: CUDA improved to be interpreted as a language, not an external package.

- PrePost Scripting: Creation of Custom Curves and Custom Properties through scripting.

The latest enhancements in Ansys Rocky software continue to push the boundaries of particle simulation offering greater accuracy, performance, and usability across a wide range of applications. Whether you’re modeling complex material behaviors, exploring advanced couplings, or optimizing large-scale systems, this release is designed to help you achieve better results.

Read Also: Ansys Rocky 2025 R1 Release Highlights

Ansys Rocky product is the industry-leading discrete element method (DEM)

software used for simulating the motion of granular

and discontinuous material.

Learn more about Rocky in Ansys Rocky Innovation Space.

-

Introducing Ansys Electronics Desktop on Ansys Cloud

The Watch & Learn video article provides an overview of cloud computing from Electronics Desktop and details the product licenses and subscriptions to ANSYS Cloud Service that are...

How to Create a Reflector for a Center High-Mounted Stop Lamp (CHMSL)

This video article demonstrates how to create a reflector for a center high-mounted stop lamp. Optical Part design in Ansys SPEOS enables the design and validation of multiple...

Introducing the GEKO Turbulence Model in Ansys Fluent

The GEKO (GEneralized K-Omega) turbulence model offers a flexible, robust, general-purpose approach to RANS turbulence modeling. Introducing 2 videos: Part 1 provides background information on the model and a...

Postprocessing on Ansys EnSight

This video demonstrates exporting data from Fluent in EnSight Case Gold format, and it reviews the basic postprocessing capabilities of EnSight.

- Rocky GPU Buying Guide

- Enhance your simulations with Rocky Ready-to-use Modules

- Ansys Rocky 2024 R2 Release Highlights

- Automate with Rocky Ready-to-use Scripts

- Ansys Rocky 2025 R1 Release Highlights

- Ansys Rocky 2024 R1 Release Highlights

- Ansys Rocky 2025 R2 Release Highlights

- Customize with Ansys Rocky Solver SDK Package

- Ansys Rocky + Ansys EnSight: Leveraging Simulation Postprocessing to new levels

- 5 great Rocky Modules to improve your simulations

© 2026 Copyright ANSYS, Inc. All rights reserved.