-

-

March 29, 2024 at 7:54 pm

ENeo178

SubscriberHi, I hope you is well!

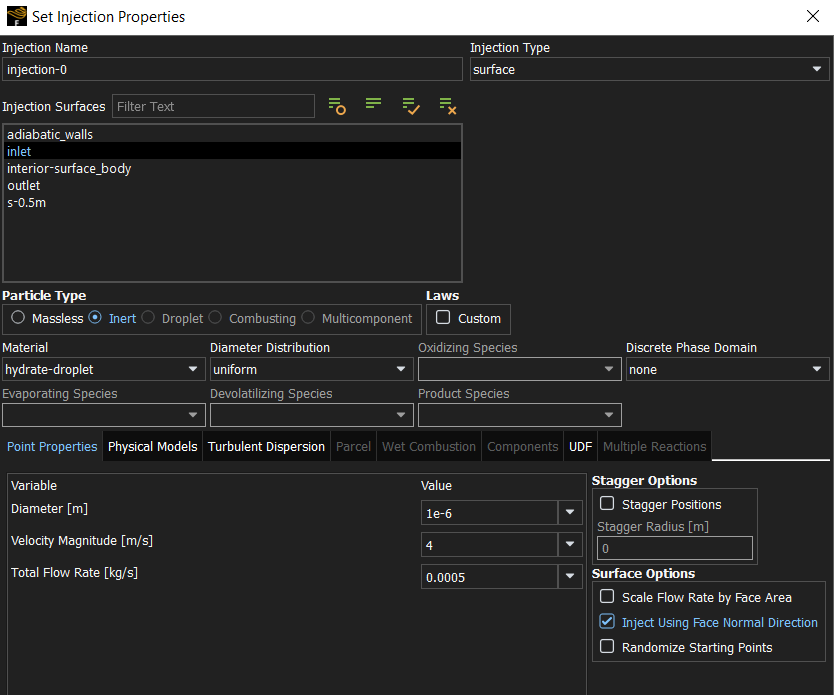

I am trying to simulate a single particle size using the surface injection type and I am not getting no results after every completed simulation and I do not know why that is the case. Below is a snapshot of the injection type window before initialisation. Could one kindly provide some insi

ghts to setting up particle injection using the surface type ?

ghts to setting up particle injection using the surface type ?Thanks

-

April 2, 2024 at 2:59 pm

Rob

Forum ModeratorThe injection looks sensible. When you say "no results" what is happening?

-

April 2, 2024 at 3:51 pm

ENeo178

SubscriberHi, thanks for your reply.

I have used the following formula to calculate the total mass flow rate (kg/s) = volume fraction/volume of particle multiplied by the area of the geometry (2D pipe) and by the particle velocity, and the calculated value 11 kg/s. However, the solver could not complete the calculation with the message ''reverse flow'' ''turbulent viscosity limited'' and ''floating point error'' when this value is set. Hence, I set the value to default (1e-20) and the simulation completed but the solver returns a value zero for particle radial distribuion even when it says some particles are trapped on the walls.

Some assistance with setting the mass flow rate and how many particles are injected when the surface type injection is set would be boost.

Many thanks,

-

April 2, 2024 at 4:05 pm

Rob

Forum ModeratorWhat fluid flow rate are you expecting/setting? Please read up on parcel theory, with the injection you're adding parces not particles so a surface injection adds the mass you set split between the surface facets.

-

April 3, 2024 at 1:23 pm

ENeo178

SubscriberDoes parcel represent the number of individual elements on the intended surface ?

And for the mass flow rate using the formula rho x A x V will result to a very high value. I have opted for transient system and was able to define the number of particles but not for the mass flow rate.

-

April 3, 2024 at 1:49 pm

Rob

Forum ModeratorNo, parcel is the container for the particles. We can't model every single particle in most cases so use parcel theory.

Flow boundaries are for the carrier (continuous) phase. Injections (which can be attached to a boundary surface) are for the particles/droplets/bubbles in DPM. So, what is the fluid flow rate?

-

April 3, 2024 at 2:15 pm

ENeo178

SubscriberThe flow rate for the continuous phase is 24 metre cubic per second. A rectangular 2D surface D=0.2m and L=30m with inlet V=4m/s.

-

April 3, 2024 at 2:18 pm

Rob

Forum ModeratorOK, so have you set the flow boundary to represent that?

-

April 3, 2024 at 2:23 pm

ENeo178

SubscriberYes I did and the same value was assigned for the particle velocity variable for the injection setup.

-

April 3, 2024 at 2:25 pm

Rob

Forum ModeratorTurn off the DPM model. How does the flow field look once it's converged?

-

April 3, 2024 at 2:31 pm

ENeo178

SubscriberThe velocity profile is a nealtly parabolic plot onced it''s converged.

-

April 3, 2024 at 2:48 pm

Rob

Forum ModeratorOK, and what is the volume fraction of the solids near the inlet (hand calculation, not from the solver)?

Basically, when a model fails the best way to troubleshoot is check the mesh and then turn everything off & then slowly turn it back on again until it breaks again. Then focus on that model/setting.

-

April 3, 2024 at 3:14 pm

ENeo178

SubscriberWhen you say solids, do you mean droplets ? If so the volume fraction is assumed to be 0.1at inlet, another issue is with the mass flow rate, since I have opted for transient method and I have defined the constant number for particles, I find it a challenging to calculate the mass flow rate kg/s, as I have used rho x v x but the value was rather too large, and the solver will not run. So how do you accurately calculate the total mass flow rate and does the total mass fow rate account for the constant number of particle assgned in a parcel ?

-

April 3, 2024 at 3:20 pm

ENeo178

SubscriberI have read up on the parcel concept and below are some highlights

- By choosing the constant-number method, the exact number of particles in each parcel could be defined. Then, the number of parcels is automatically calculated by the software to satisfy the mass flow rate of the injection

- The constant mass method specifies every parcel’s mass. The software automatically calculates the number of parcels to satisfy the mass flow rate of the injection.

- The constant-diameter method lets users specify parcel diameter.

The first option was selected, does it mean that the total mass flow rate in the point properties be assumed zero and let the solver calculate the mass rate as I have defined 1.4e6 total number of particles ?

-

April 3, 2024 at 3:32 pm

Rob

Forum ModeratorIn the real system you have a mass flow of droplets, in kg/s. That number goes into the injection panel, along with speed and a starting location. The speed and kg/s are NOT related for the injection as these are discrete droplets/particles. Turn off DDPM, at 10% it's not necessary to begin with, you may need to couple the DPM model, but that also depends on the flow field. Now re-run and see what's going on.

-

April 3, 2024 at 4:31 pm

ENeo178

SubscriberSo I should run the simulation only using the DPM model while the mutltiphase model remain off

-

April 4, 2024 at 8:18 am

Rob

Forum ModeratorTo start with, yes. If you're using droplets I'd run DPM or Eulerian with other models as needed; it would be very unusual to run DDPM for droplets.

-

April 24, 2024 at 11:57 am

ENeo178

SubscriberOkay. I was able to run a few simulation using the DPM, however, Id'like to ask if the numbers tracked mean particles ? And if so how come when 0.1146 kg/s is set to acccount for 0.1 percent vf of the particles, only 42 number is tracked but not more ? And is there any technique to increase the number of particles being tracked ?

-

April 24, 2024 at 12:45 pm

Rob

Forum ModeratorYou're tracking parcels. So, 42 parcels are tracked each holding 0.1146/42 kg/s. Each parcel trajectory is calculated based on the diameter & material property you set in the injection. Read up on Parcel Theory for a more complete explanation.

In Fluent the reports/settings for particle should have been labelled as parcel in most instances. As the terms were muddled up in about v3 there's not much chance of them being corrected.

-

April 24, 2024 at 1:53 pm

ENeo178

SubscriberOkay, thank you for your assistance

-

April 26, 2024 at 9:32 am

ENeo178

SubscriberHi,

How can I calculate the number parcels/particles at several x positions of the pipe ?

-

April 26, 2024 at 10:24 am

Rob

Forum ModeratorHave a look at the DPM Report functions.

-

May 3, 2024 at 10:14 am

ENeo178

SubscriberHi,

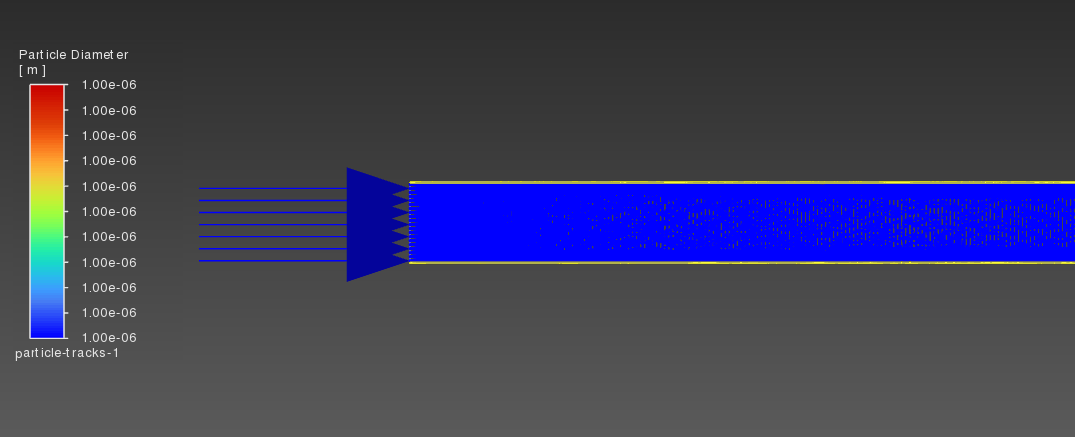

I want to know why is my geometry (horizontal pipe) filled with parcels/particles when I select surface injection (inlet) type but only 740 parcels are tracked ?

-

May 3, 2024 at 10:24 am

Rob

Forum ModeratorPlease post some images. DPM Tracks and volume fraction as a minimum.

-

May 3, 2024 at 10:39 am

-

May 3, 2024 at 11:49 am

Rob

Forum ModeratorA surface injection will release one parcel per surface facet. If you've then turned on stochastic tracking with 37 tries, total injected parcels will be facet count time tries (some x 37).

-

May 3, 2024 at 12:42 pm

ENeo178

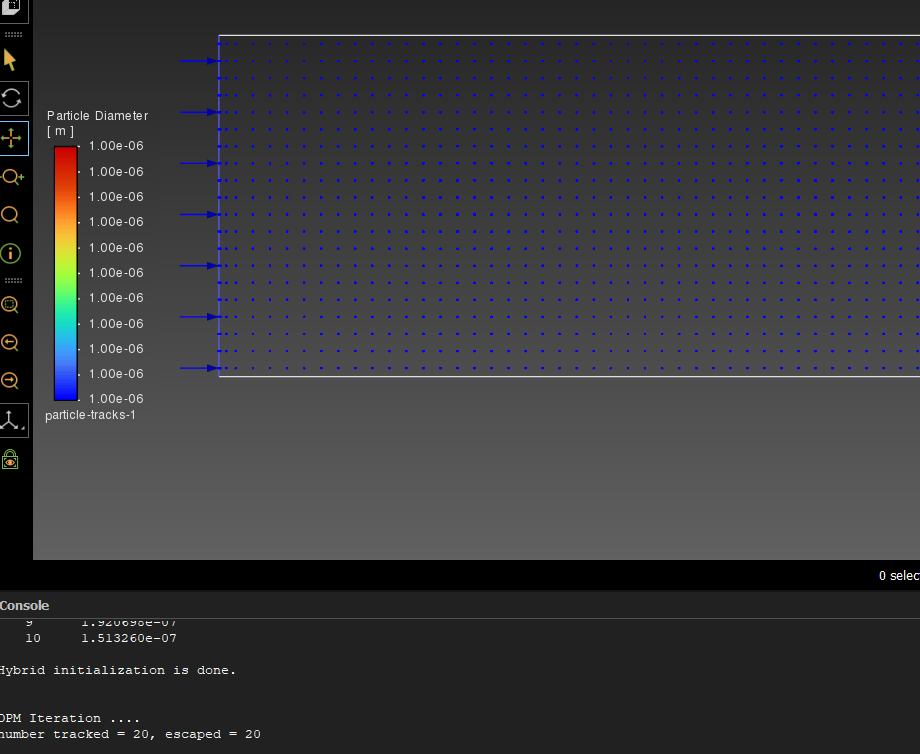

SubscriberYes I am familiar with the stochastic tracking effect, but even when the stochastic tracking is selected to none, only 20 parcels are injected and the surface is still filled with parcels as shown below, please could you explain why that is the case ? My own understanding is that since the system is steady state the domain will be filled with particle parcels that have accumulated over the iteration/time history but I might be wrong.

-

May 3, 2024 at 1:02 pm

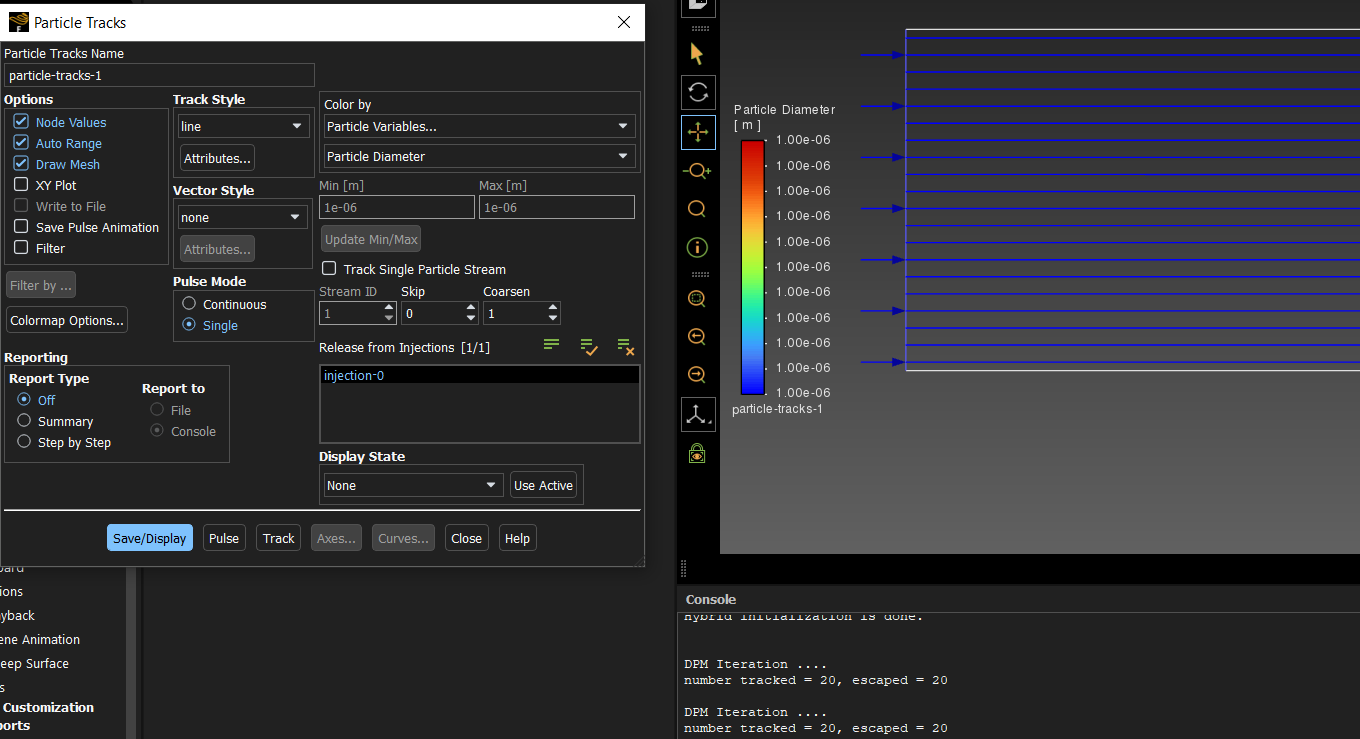

Rob

Forum ModeratorPlease can you post the DPM set up panel? For steady I'd expect to see particle pathline and not particle point positions.

-

May 3, 2024 at 1:10 pm

-

May 3, 2024 at 1:15 pm

Rob

Forum ModeratorRight, so you are seeing the lines as I'd expect. Assuming the flow is left to right I'm not sure what isn't as expected in the result.

-

May 3, 2024 at 1:53 pm

ENeo178

SubscriberMy misunderstanding. The set up is correct, though I want to know how the particles could be increased without turning the stochastic effect or does fluent sume parcels number to number of cells at the surface ?

-

May 3, 2024 at 3:27 pm

Rob

Forum ModeratorYou could adapt the inlet surface, that increases the facet count and therefore the number of parcels. Otherwise there are file and line/rake from just inside the domain.

-

May 3, 2024 at 8:55 pm

ENeo178

SubscriberThank you Rob

-

- The topic ‘Using Dense Discrete Phase Model Injection Type’ is closed to new replies.

-

3477

-

1057

-

1051

-

945

-

912

© 2025 Copyright ANSYS, Inc. All rights reserved.