TAGGED: excessive-distortion, fsi-2-way, two-way-fsi

-

-

January 1, 2025 at 11:03 pm

Farah

SubscriberI'm setting up a two-way FSI simulation, but it keeps crashing due to excessive thickness change errors in ANSYS. The CFD part (Fluent) works perfectly, but the issue arises when coupling it for FSI.

I’ve used wall properties with a density of 1000, a Young’s modulus of 2 MPa, and a Poisson’s ratio of 0.49 (these are rough estimates). Despite this, my model keeps crashing. The only time I managed to get the two-way FSI to run was when I used wall properties resembling structural steel, which isn’t physiologically appropriate for this scenario. (fluid is Blood)

Do you have any insights or suggestions?

-

January 3, 2025 at 8:54 am

Rahul Mule

Ansys EmployeeHave you tried running mechanical only part with representative load to see if that works?

Could you please share the exact error?

Please try lowering the time steps and using data transfer under relaxation.

-

January 3, 2025 at 4:29 pm

Farah

Subscriberyes each module independently works fine : Structural and Fluent

but when i couple it i recieve this error: “Element 7438 has excessive thickness change.”

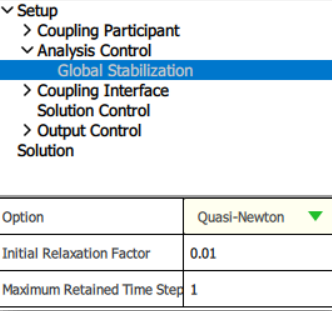

i tried URF, global stabilization, different RMS convergence target but still fails! im super frustrated cause tried different time step but again same error occurs

-

-

January 3, 2025 at 4:37 pm

Rahul Mule

Ansys Employee-

January 3, 2025 at 4:41 pm

Farah

Subscriberi activate this option in SC but same error occured! decreased my time-step to 0.0001 but recieved the error

and idk why when i use structural steel it works just fine

am i missing something in dynamic mesh?

-

-

January 3, 2025 at 4:44 pm

Rahul Mule

Ansys Employee-

January 3, 2025 at 5:07 pm

Farah

Subscriberthis option is on and when i changed it it take a little bit longer before it fails

-

-

January 6, 2025 at 6:17 am

Rahul Mule

Ansys EmployeeOkay. Please share more details about the setup from both participants and System Coupling.

-

January 7, 2025 at 2:06 pm

Farah

SubscriberDo you want me to upload it here? I know it will be publicly displayed

-

-

January 7, 2025 at 2:59 pm

Rahul Mule

Ansys EmployeeIf it is confidential data, do not share.

Check your BCs, and material properties.

The default value of the scale factor might not work. This factor will be different for different time steps or for a different case.Always start with small values then increase. (Note that pressure response is a function of scale factor and Number of Fluent iterations per coupling step). So in practice, consider using a small number of Fluent iterations between each mesh update.

-

- You must be logged in to reply to this topic.

-

3402

-

1052

-

1050

-

891

-

872

© 2025 Copyright ANSYS, Inc. All rights reserved.