-

-

January 28, 2020 at 9:26 pm

ham_nola

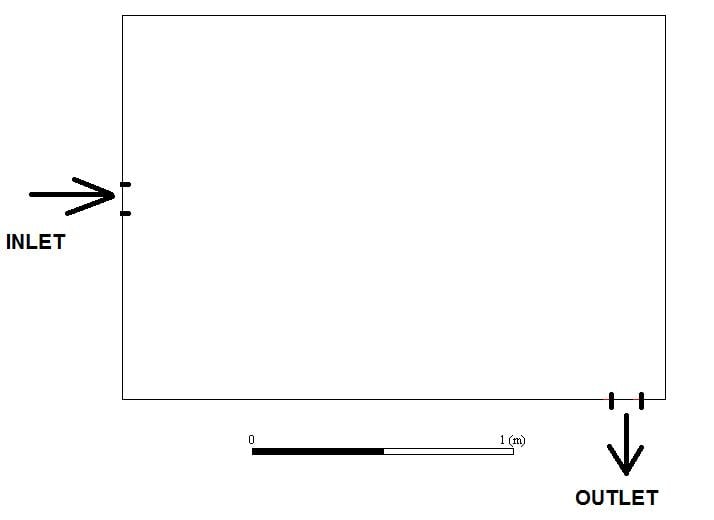

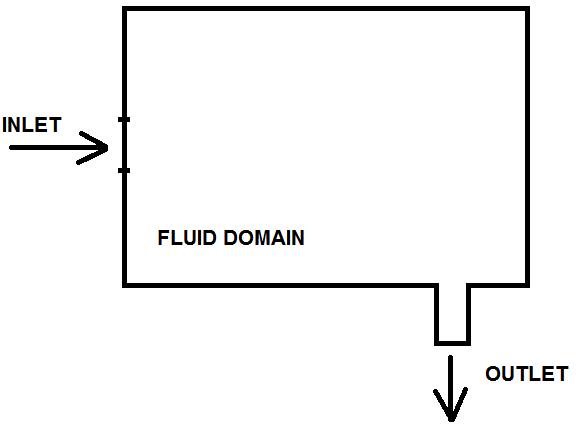

SubscriberI have two phase flow (water vapor and liquid water) in a rectangular domain with inlet of the left and outlet at the bottom. The domain is two dimensional (2D). The domain has gravity acting in the -ve Y direction. I used the Eulerian model for the two phases. I have velocity inlet and pressure outlet BC.

I follow the following steps:

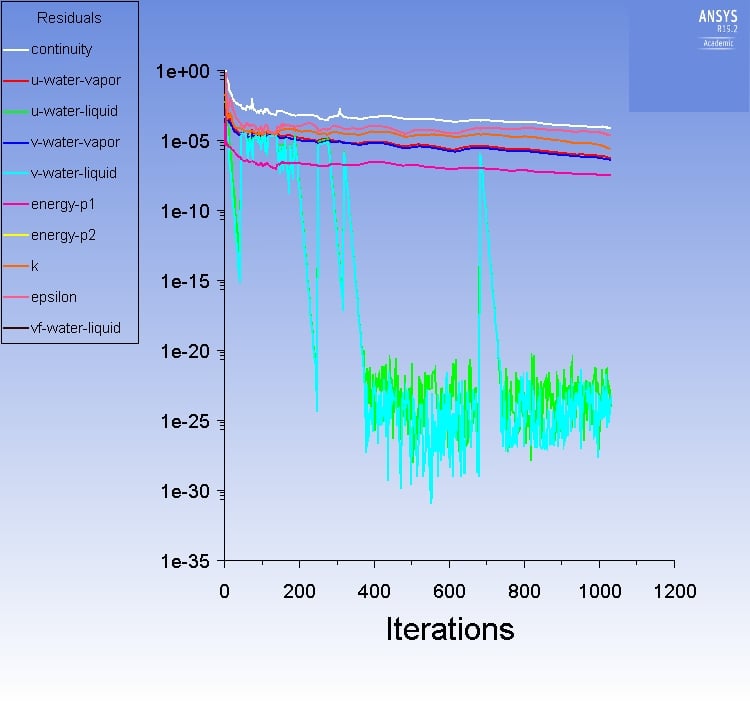

1. Pseudo-transient analysis with only water-vapor entering the domain. It converges and the results are perfect. The residual plots are as shown below

2. Pseudo-transient analysis with water-liquid volume fraction of 0.1 at the domain inlet. I cannot get convergence. The solver diverges stating that "turbulent viscosity ratio" is higher than 1e5.

I looked into the turbulent viscosity ratio warning. My maximum skewness is 0.02, so the mesh is okay. I tried the recommendation to turn off turbulence for 100 to 200 iterations and turning them back on...but the solution diverges.

I even tried a laminar case, and the solution diverges! I tried transient case, but the solution diverges!

I would be grateful if the expert users out there could recommend me something!

Thank you.

-

January 29, 2020 at 6:10 am

Amine Ben Hadj Ali

Ansys Employee1/Please also include other information like phase interaction panel, etc..

2/Your first run you say it converged: it is not perfect but it runs

3/Did you try transient?

4/What is the initial state in the domain? filled with vapor?

5/Water liquid the dispersed phase?

-

January 29, 2020 at 4:13 pm

ham_nola

SubscriberDear Amine

Thank you for your response.

Case 1: Water vapor entering the domain through the inlet. Solution converges when I use the Pseudo-transient.

Case 2: Water vapor with 0.1 volume fraction of Water liquid entering the domain through the inlet. This case is initialized from Case 1. The solution diverges and I use Pseudo-transient.

In reference to what you asked:

1). Water vapor is my primary phase and water liquid is the secondary phase. I have virtual mass coefficient = 0.5.

The drag coefficient is symmetric.

The lift, wall lubrication, surface tension, turbulent dispersion and turbulent interaction as not considered.

Heat transfer coefficient is considered for both vapor and liquid as a two-resistance model with Nusselt number defined using ranz-marshall correlation.

There is no mass transfer between the phases.

The interfacial area is ia-symmetric.

2. Yes, so if I have just water vapor entering the domain, it converges using the Pseudo-transient (lets name it Case 1). The problem arises when there is a volume fraction 0.1 water liquid entering the domain, then it diverges. (say Case 2)

3. I have tried transient as well. But the transient case also diverges with the error of high turbulent viscosity ratio.

4. Yes. I initialize the case from the results of Case 1.

5. Yes, my primary phase is Water Vapor and dispersed/secondary phase is Water Liquid.

Thank you.

Best regards,

Hamed.

-

January 29, 2020 at 4:17 pm

ham_nola

SubscriberPrimary phase: For Water Vapor I define density as ideal gas and C_p as piecewise-polynomial. All other properties are constant.

Secondary/Dispersed phase: For Water Liquid I define it as constant diameter 0.001 m and all properties are constant.

-

January 29, 2020 at 4:50 pm

Amine Ben Hadj Ali

Ansys EmployeeDo not initialization case 2 run transient and switch off virtual mass. Probably you need two resistance model and thermal phase turned on. Also check turbulence input at inlet and reduce time step size. -

January 29, 2020 at 5:52 pm

ham_nola

SubscriberDear Amine,

The turbulent conditions at the inlet are turbulent intensity of 3.7 % [% I = 0.16(Re_Dh)^(-1/

x 100] and hydraulic diameter = actual diameter of inlet pipe = 0.0254 m (or 1").

x 100] and hydraulic diameter = actual diameter of inlet pipe = 0.0254 m (or 1").

I am running a 2D case, is hydraulic diameter = diameter of inlet correct? I say this as this is a 2D case, and considering Fluent gives a depth of 1 m for 2D cases, the inlet is more of a rectangular duct than a circular pipe!

I will run a case with the setting you mentioned, thank you.

Best regards,

Hamed.

-

January 29, 2020 at 8:20 pm

ham_nola

SubscriberDear Amine,

The initialization you mentioned is the standard initialization? I did a case run with your recommendation, except without considering phase change. I am getting reversed flow at outlet and turbulent intensity high warning! Please let me know if you need further details and I will send screenshots.

Thank you.

Regards

Hamed

-

January 30, 2020 at 5:36 am

Amine Ben Hadj Ali

Ansys EmployeeDo provide low turbulence level at inlet and outlet and realistic backflow boundary quantities. Start from zero field and use mixture turbulence model. -

February 3, 2020 at 6:47 pm

ham_nola

SubscriberDear Amine,

I made the following changes according to you instruction:

1. Run the case as transient

2. Used turbulence model for the mixture

3. Initialized the domain with zero velocity field

4. Turned off the virtual mass force

5. Turned on the two-resistance model (with Nusselt number estimated from the Ranz-Marshal correlation.

6. Turn on the evaporation-condensation model with T_sat defined as piecewise linear function of pressure.

7. Turbulence intensity is 3.7 % and I define hydraulic diameter (1")

The good thing is that the solution is running!

In the initial time steps the reversed flow warning still appears...should I ignore it? Or, may be run more iterations per time step...currently, its 100 iteration/time-step.

Thank you.

Best regards,

Hamed.

-

February 4, 2020 at 6:19 am

Amine Ben Hadj Ali

Ansys EmployeeYou are exaggerating with number of steps each time step. Not more than 10 max 20. For the outlet you can extend it and make like a venturi pipe to increase dynamic pressure Or connect it to a plenum with horizontal pressure opening. -

February 4, 2020 at 4:14 pm

-

February 5, 2020 at 6:09 am

Amine Ben Hadj Ali

Ansys EmployeeVentu pipe as convergent nozzle. My idea is to avoid any kind of nonphysical reversal flow. -

February 5, 2020 at 4:17 pm

ham_nola

SubscriberDear Amine,

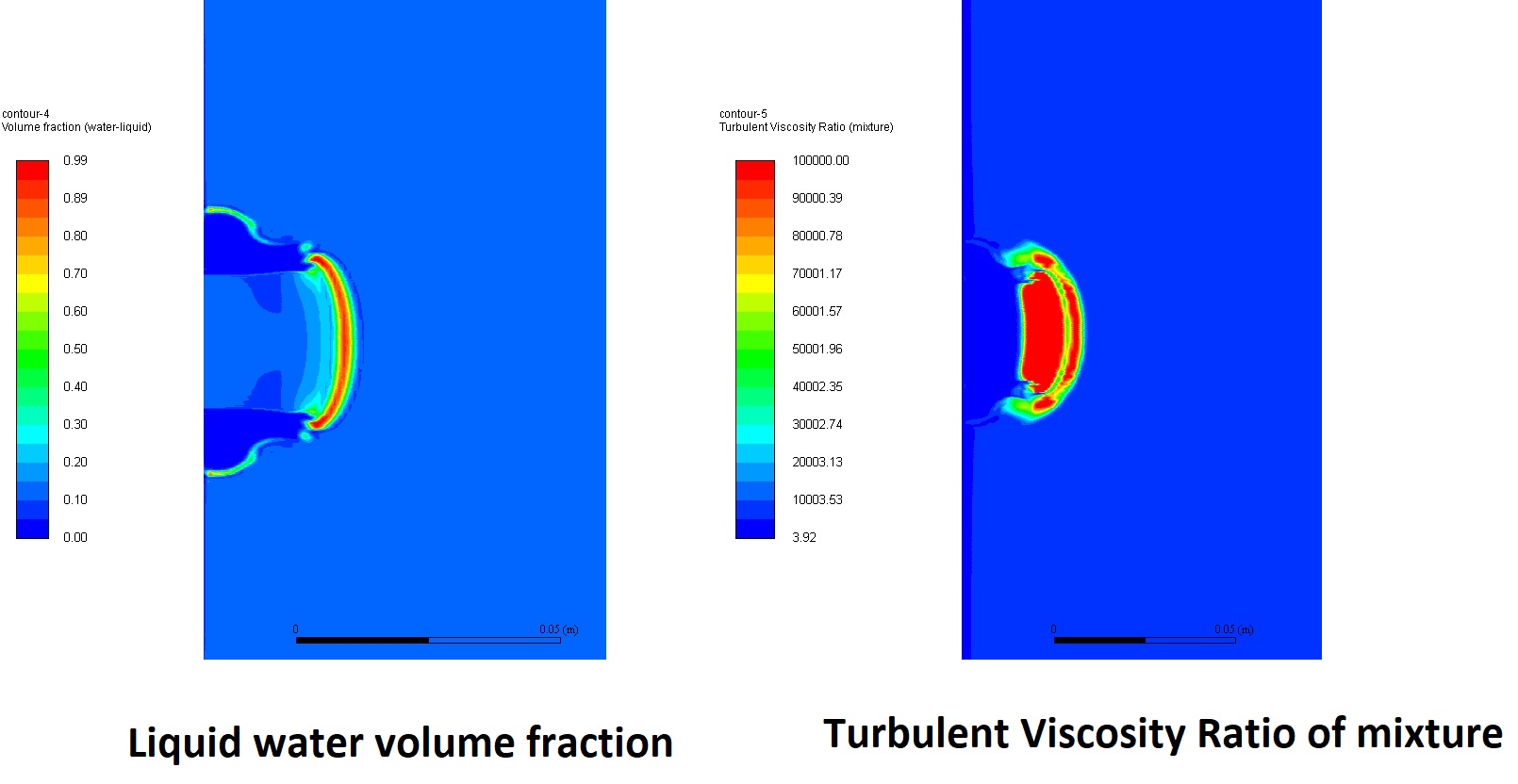

I have a turbulent case up and running with the old geometry! It's not showing any flow reversal now. I have the following questions:

1. The turbulent viscosity ratio > 1e5 is still there! I have defined a turbulent intensity of 1 % (previously it was 3.7 %). Below is the zoom-in image of the turbulent viscosity ratio and water liquid volume fraction. My understanding is that the turbulent viscosity ratio is higher where the water vapor condenses to water liquid!

Should I ignore the warning of high turbulent viscosity ratio?

2. Currently, I have set the global courant number to 0.75 and using variable time-step (e.g. now the time step is 1e-6 seconds). The simulation is running super slow. Please can you suggest how can I accelerate it? I tried Courant number of 2, but the solution diverges!

Thank you.

Best regards,

Hamed.

-

- The topic ‘Two phase flow in a rectangular domain’ is closed to new replies.

-

4683

-

1565

-

1386

-

1242

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.