TAGGED: ansys-mechanical, ansys-thermal, transient-thermal

-

-

May 29, 2025 at 7:31 pm

danielem

SubscriberI am trying to run a transient thermal simulation on a biological tissue model.

Problem Setup:

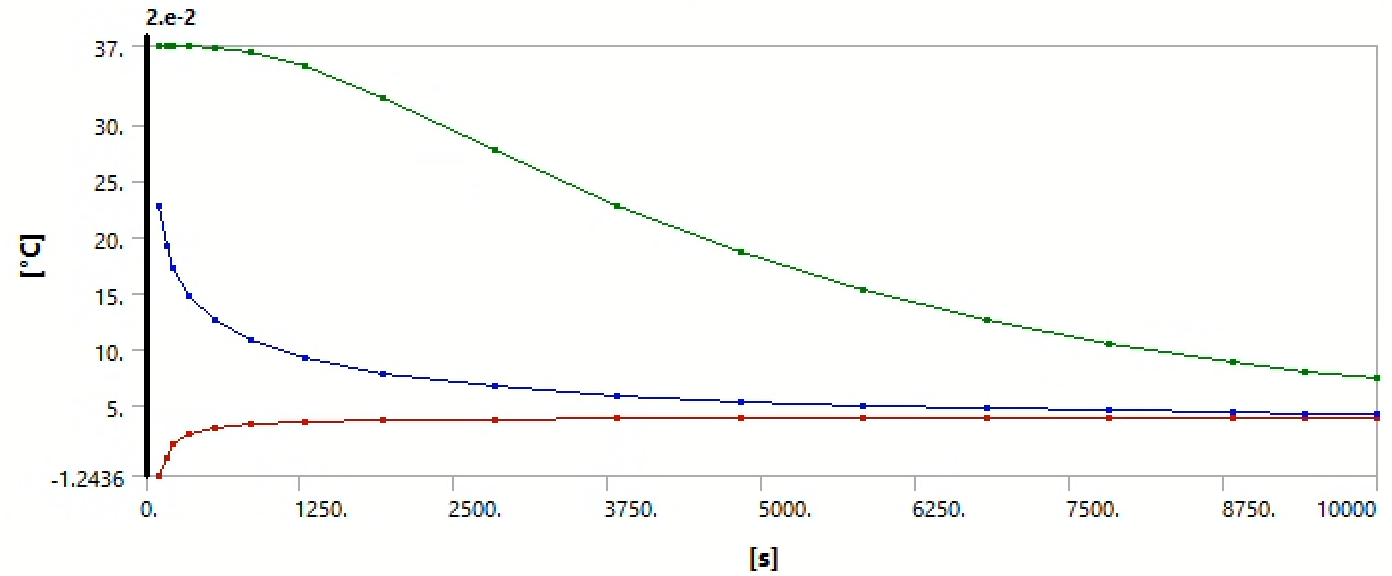

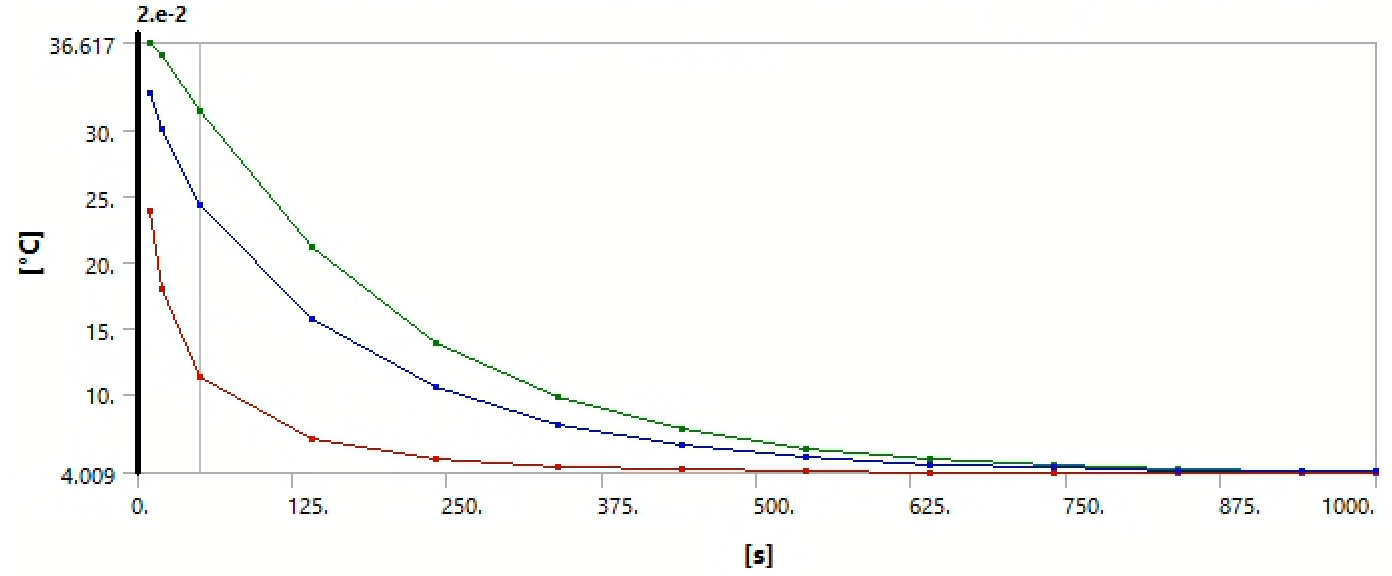

I set the initial temperature of the model to 37C, and then impose a convection boundary condition on the surface of the model with an ambient temperature of 4C. I use the same exact mesh for each simulation. There is a 5 layer inflation layer, and 80,000 total elements. The thermal properties used are detailed below.Issue:

When I run the simulation for the properties of my biological tissue, there is a spike in themaximum andminimum temperature during the first couple time steps. This issue has persisted even as I have refined the mesh, added inflation layers, and used smaller time steps.

Tissue properties: rho = 7850 kg/m^3, k = 60.5 W/m-K, c_p = 434 J/kg --> alpha = 1.78e-5 m^2/sThis is contrary to when I run the simulation with the properties of structural steel, where the simulation appears to be very well behaved (e.g. the maximum and minimum temperatures are bounded by [4,37]C and all three temperatures (max, min, avg) asymptotically decreases towards steady state.

Steel properties: rho = 1070 kg/m^3, k = 0.512 W/m-K, c_p = 3394 J/kg-K --> alpha = 1.41e-7 m^2/s

Question: Is there any specific reason why the simulation is so poorly behaved for the biological tissue properties? I understand the thermal diffusivity has ~2 order of magnitude difference, but I would think if anything this should make the tissue simulations more stable for large time steps. Does anyone have recommendations for modifications I can make to my simulation? Let me know if you need additional information, thanks.

-

May 30, 2025 at 5:34 am

Erik Kostson

Ansys EmployeeHi

Looks like a thermal undershoot.

Search the site here or use AI assistant, or ANsys GPT.

Below is what we get if we search online:In Ansys, ITS (Initial Transient Step) is a critical parameter to consider in transient thermal analysis to avoid thermal undershoot, a phenomenon where the simulated temperature drops below physically possible values. Undershoot can occur when using quadratic elements (elements with midside nodes) or when the time step size is set too small relative to the mesh size and material properties.To address thermal undershoot:- 1. Determine ITS:Calculate the minimum time step size (or maximum element size) based on the following formula: ITS = Δ² / 4α, where Δ is the conducting length of an element, and α is the thermal diffusivity.

- 2. Consider Element Type:Avoid using quadratic elements with midside nodes, as they are more prone to oscillations and undershoot. Linear elements (without midside nodes) are generally preferred for transient thermal analysis.

- 3. Mesh Size:Ensure the mesh size is compatible with the chosen time step size to prevent undershoot.

- 4. Time Step Selection:Choose a time step size that is appropriately large to capture the transient heat flow but not so large that it causes undershoot.

- 5. Material Properties:Accurately define the material properties (thermal conductivity, density, and specific heat) to ensure the calculated ITS is correct.

- 6. Biot and Fourier Numbers:Use the Biot and Fourier numbers to guide the selection of the time step size in transient thermal analysis, as explained in a presentation by Ansys Innovation Space.

All the bestErik

-

- You must be logged in to reply to this topic.

-

3150

-

1013

-

945

-

858

-

797

© 2025 Copyright ANSYS, Inc. All rights reserved.