-

-

May 27, 2024 at 1:25 pm

Abhemanyu Palaniswamy Chandrasekaran

SubscriberHello, I am trying to set up an FSI simulation. I want to manually define the coupling pressure using a load curve ID.

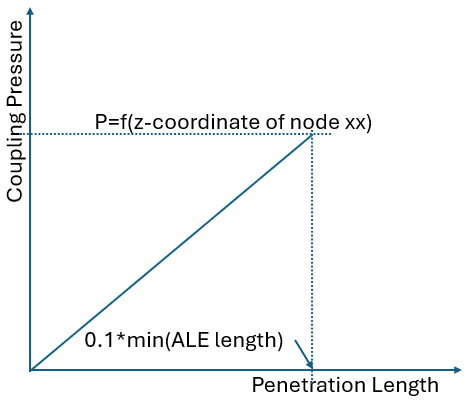

For the pressure as a function of penetration depth, I want to scale the coupling pressure values depending on the Z coordinate of a node on my lagrangian structure. To get the Z coordinate of the node, I can use the *DEFINE_CURVE_FUNCTION keyword.

How do I use this obtained z coordinate to define a scale factor for the coupling pressure curve?

The coupling pressure curve must have the penetration as the absissca and the scaled(time varying and depends on z coordinate) value of the coupling pressure as the ordinate.

-

May 30, 2024 at 2:48 pm

Ian Do

Ansys EmployeeHello Abhemanyu,

Please share some info: Based on what physics that you can scale this FSI curve this way? What is a real physical scenario?

The FSI loading is based simply on the amount of penetration of the ALE mat across the LAG surface, the same as Penalty contact, or spring-like interaction.

Ian Do

-

May 30, 2024 at 2:55 pm

Abhemanyu Palaniswamy Chandrasekaran

SubscriberHi Ian,

I want to simulate a floating object that oscillates freely in water. I want to use the z coordinate of the deepest point of the floating object to calculate the hydrostatic pressure acting at that point. Then this hydrostatic pressure will be used to define the maximum coupling pressure in the load curve.

With the default values of PFAC, I find some numerical oscillations in the solution of the rigid body kinematic quantities. I would like to try using a coupling pressure load curve to see if these oscillations can be minimized.

Thanks & Regards

Abhemanyu

-

May 30, 2024 at 3:35 pm

Ian Do

Ansys EmployeeHello Abhemanyu,

Penalty method is always noisy by definition because we first allow for the penetration in this time step. Then correct or push back in the next time step. The applied force is not based on physical law (like Newton's) but based on ad hoc engineering estimate. There are always oscillations. Hydrostatic P is most often not the first order contribution. Other dynamic events, slamming, waves, etc. likely dominate the FSI. FSI loading is a very rough estimation at best. I do not see how a small adjustment can affect other bigger and more dominant events. A test: (a) compute P_hydro=P0+rho*g*h, (b) monitor max fluid P, (c) compare. If (a) is on the order of (b), maybe(?). Typical contact sometimes scale the force with the bulk modulus of the mats (this is very large comparing to hydrostatic range).

Ian

-

July 24, 2024 at 5:51 am

Abhemanyu Palaniswamy Chandrasekaran

SubscriberHello Ian,

Thank you very much for all your replies. They have been very helpful in successful completion of my thesis work.

Regards

Abhemanyu

-

- The topic ‘Time varying coupling pressure for SALE FSI’ is closed to new replies.

-

2979

-

970

-

857

-

750

-

599

© 2025 Copyright ANSYS, Inc. All rights reserved.