TAGGED: bonded-contact, shell-thickness

-

-

May 24, 2023 at 5:57 am

Luisa Hornung

SubscriberHello,

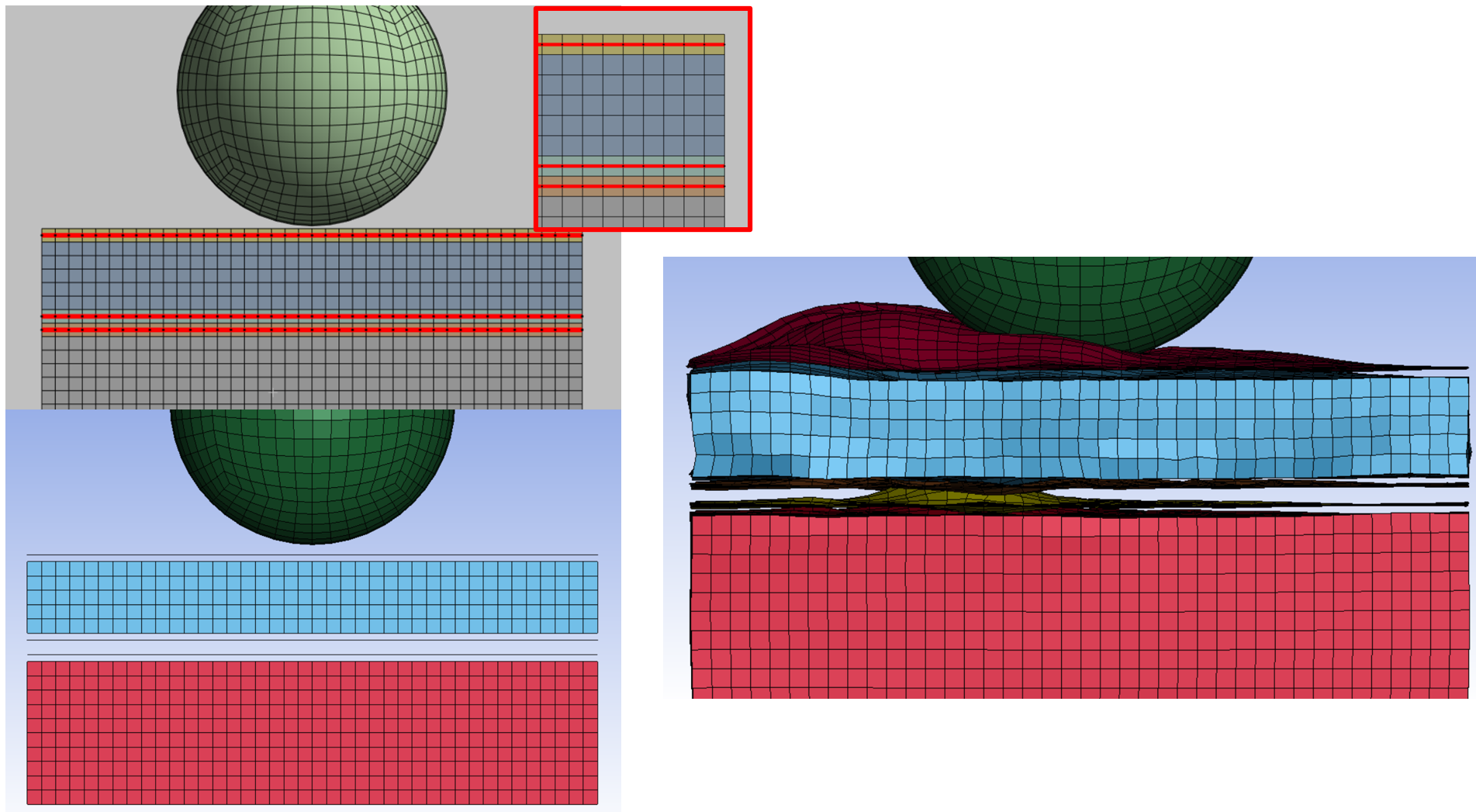

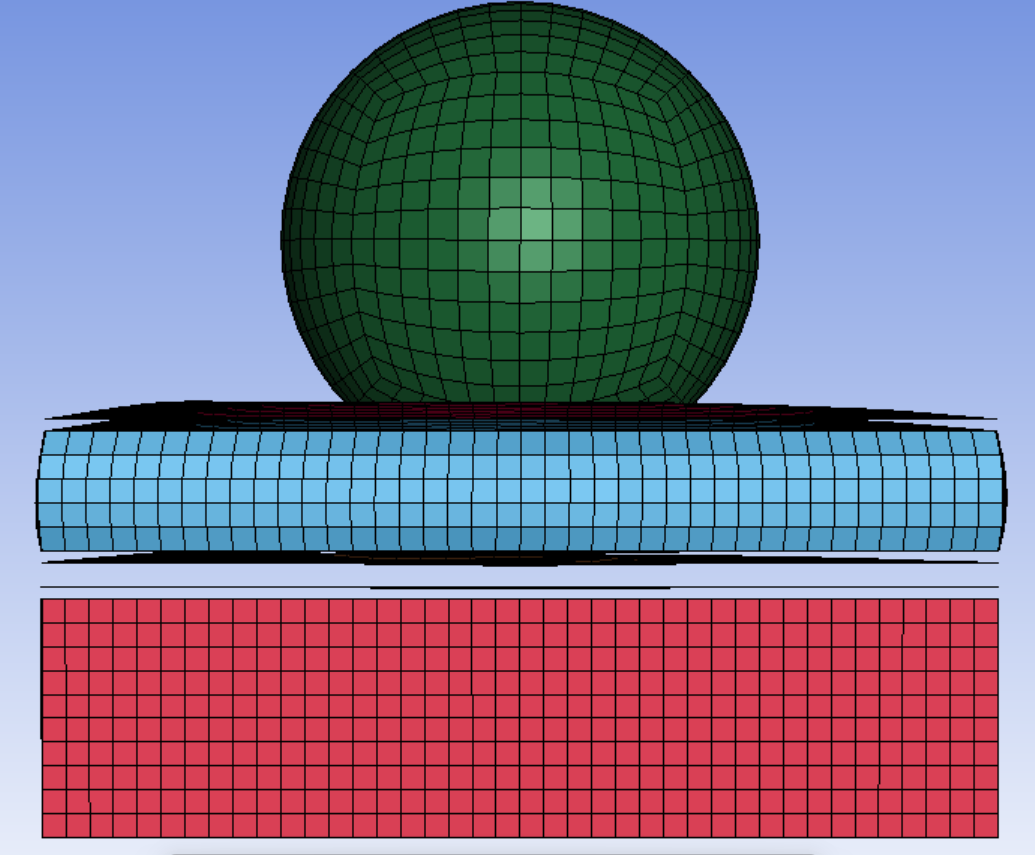

I have a 5 layered model with different materials. All layers should be bonded. I read, that when using shell elements, there should be a sufficient gap between shell and solid to consider the shell thickness (but I could not find how close "sufficient" is). In my model, all Shells have a thickness of 1 mm. I also read, that the algorithm searches for connecting nodes 1/2 of the Shell thickness in normal direction appart from the midsurface line. So I left a gap of 0.5 mm to the respective tied surface. I also set SAST and SBST to -1 mm in order to control the thickness (-0.5 mm did not work). But when running the simulation, I get an error as well as in the message file it reads: "Warning 40538 (SOL+538) Slave node is not constrained no segment was found in bucket sort." In the picture you can see on the left side the mesh on top (no overlapping elements) and the LS Dyna view at the bottom and right the solution after calculation -> the nodes are not TIED together

However, when leaving no gap between Shell elements and the corresponding tied surface, there is no warning message and no error occurs:

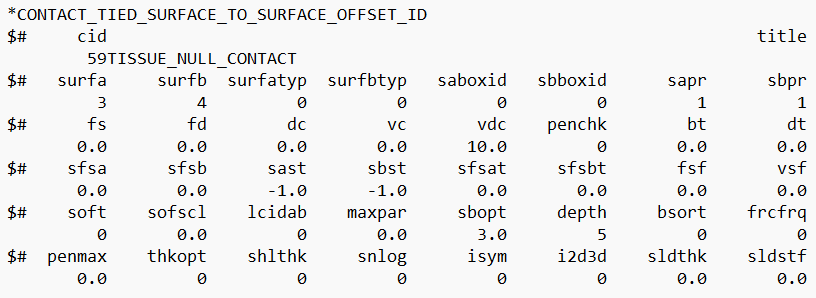

This is the contact definition for the first case (gap between Shell and Error/Warning messages):

How should the contact be defined correctly? Is case B (no gap) correct or how can I define the shell thickness for case A in order to tie the nodes together?

Thank you for your support and best wishes

-

May 24, 2023 at 2:55 pm

Jim Day

Ansys EmployeeAssuming the tied parts are not rigid, I suggest you try *CONTACT_TIED_SURFACE_TO_SURFACE_CONSTRAINED_OFFSET . That will make the tied contact constraint-based rather than penalty-based. Check your segment sets 3 and 4 to confirm those segments lie only on the surfaces you want to be tied. If you get warnings about untied nodes, boost SAST and SBST to -1.2 and if that doesn't work, as an experiment, try using positive values of 1.2. Report back your findings. -

May 24, 2023 at 2:56 pm

Jim Day

Ansys EmployeeAlso state whether you're using SMP or MPP, and what version of LS-DYNA you're using. Thanks. -

May 25, 2023 at 9:26 am

Luisa Hornung

SubscriberDear Jim,

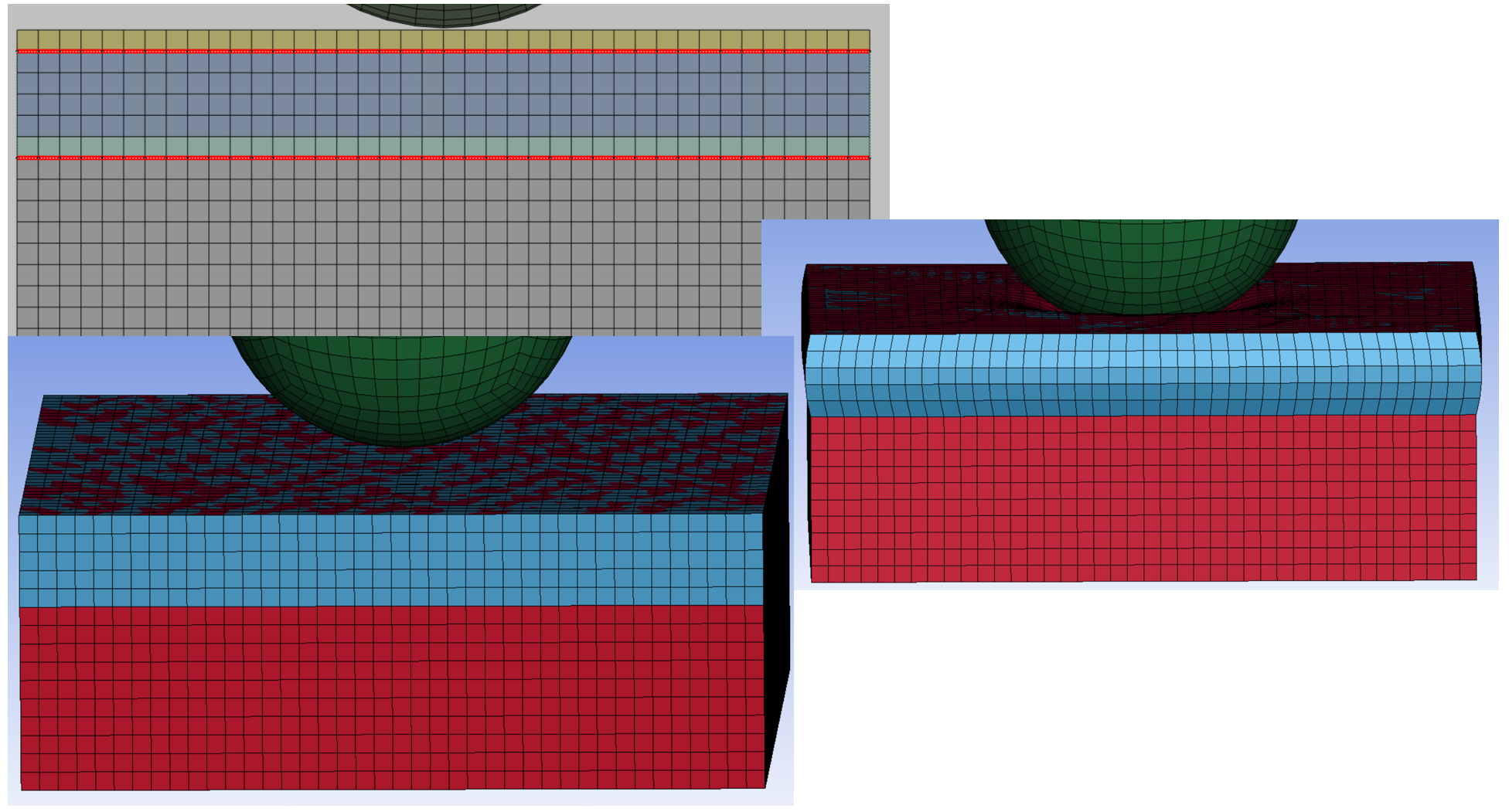

thanks for your help. I tried *CONTACT_TIED_SURFACE_TO_SURFACE_CONSTRAINED_OFFSET with SAST and SBST to -1.2 and the result looked like this:

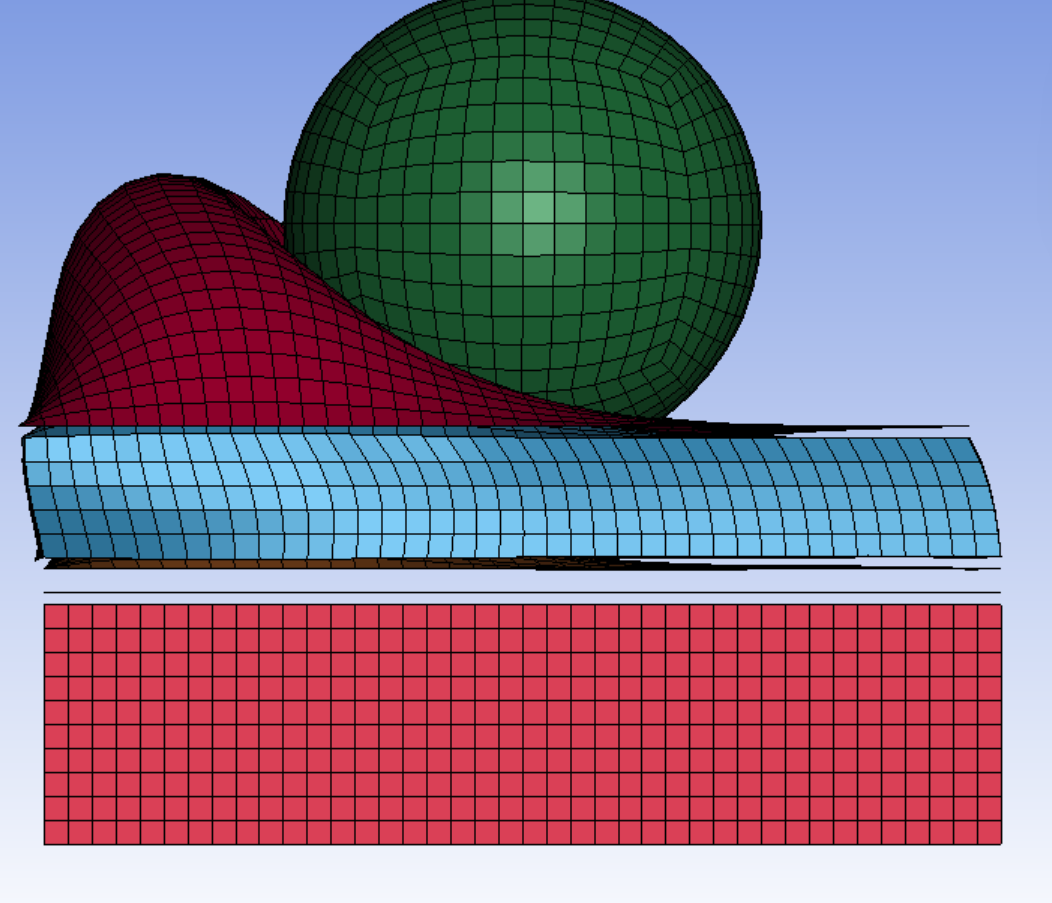

But setting SAST and SBST to +1.2 worked fine:

The problem in this case is, that the Shell Nodes are tied twice, with the part on top and the part below the shell. Therefore the warning, that the nodes are tied on two interfaces occurs. But the result looks fine.

I used SMD and LS-Run 2022 R2 with LS-Prepost V4.9.12-16Dec2022.

Thanks and best wishes

-

May 25, 2023 at 2:34 pm

Jim Day

Ansys EmployeeSounds like you're using one tied contact to do it all. I'd use two separate tied contacts: one for the blue part and one for the red part. Use unique segment sets for the SURFA side of each so there's no ambiguity of what should be tied to what. -

May 25, 2023 at 2:40 pm

Luisa Hornung

SubscriberI am using 4 Tied contacts in sum (from bottom to top):

1) red part with first shell

2) first shell with second shell

3) second shell with blue part

4) blue part with third shell

For each tied contact I use different segment sets, even when its the same shell part. That means, that I have for the first shell part 2 different segment sets for two different tied contacts

-

May 25, 2023 at 2:52 pm

Jim Day

Ansys EmployeeThen I don't understand the warning that the nodes are tied on two interfaces. Does it make sense to you? Moreover, do you consider the problem resolved? -

May 25, 2023 at 2:57 pm

Luisa Hornung

SubscriberI read somewhere that when using constraint-based contact one node can not be tied twice to different other parts. I think that is the problem. However, I consider the problem solved. Thank you for your support.

-

May 25, 2023 at 5:51 pm

Jim Day

Ansys EmployeeI reread and understand now how you could get the warnings. It may be helpful to know setting IPBACK to 1 on Card E of *CONTACT_TIED_SURFACE_TO_SURFACE_CONSTRAINED_OFFSET will create a backup penalty-based tied contact for treatment of nodes that are over-constrained by constraint-based TIED contacts. -

May 25, 2023 at 5:55 pm

Jim Day

Ansys EmployeeYou might also consider using only a single layer of shells between the red and blue parts instead of two shell layers. That combined shell layer can be defined using *PART_COMPOSITE, thereby allowing you to using different material models and different integration point thicknesses within that single shell layer.

-

- The topic ‘TIED_CONTACT for Shell Elements – Gap between Shell-Shell and Shell-Solid’ is closed to new replies.

-

4818

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.