TAGGED: AEDT-ICEPAK, computational-fluid, laminar-flow, meshing

-

-

December 19, 2025 at 12:02 pm

860854801

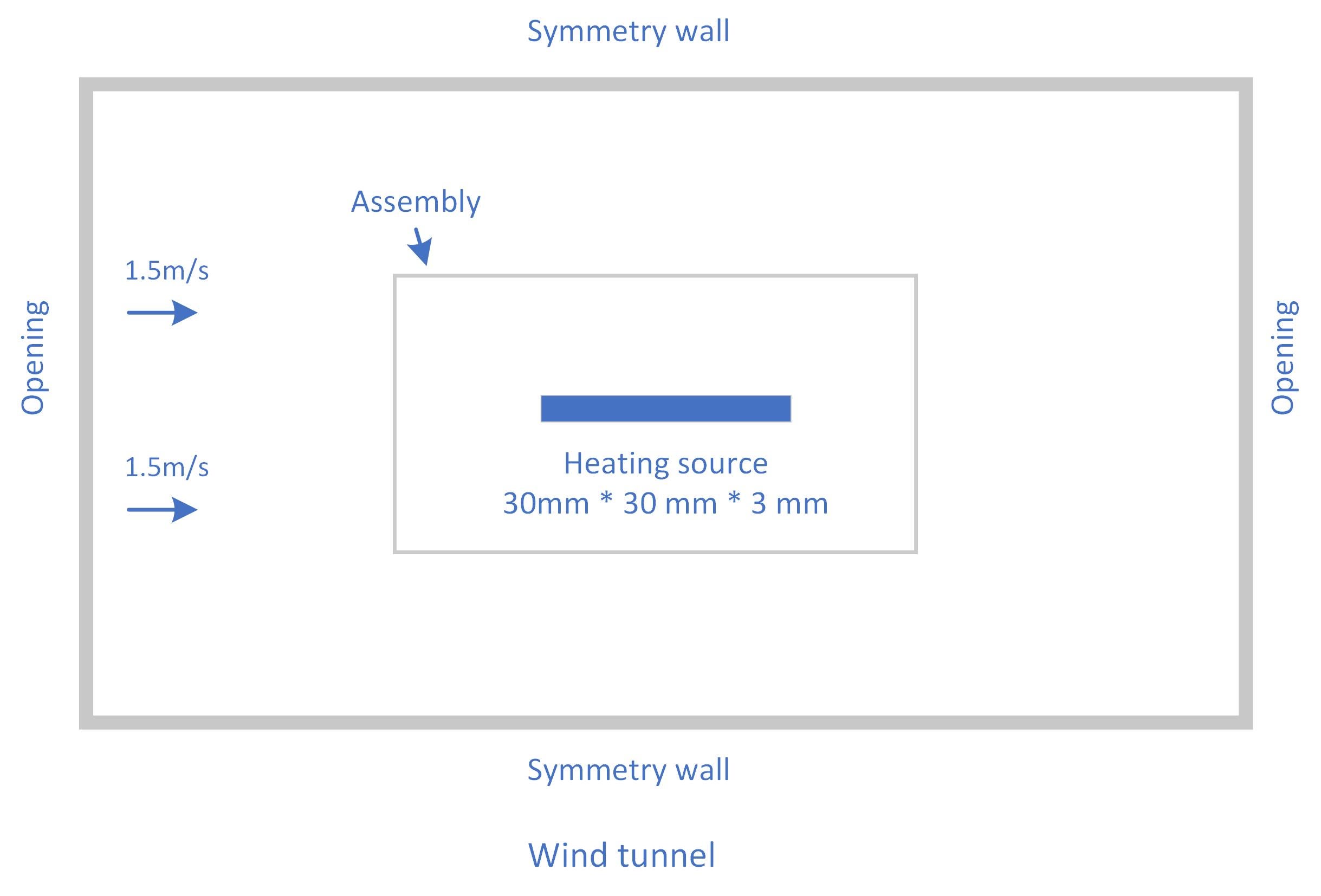

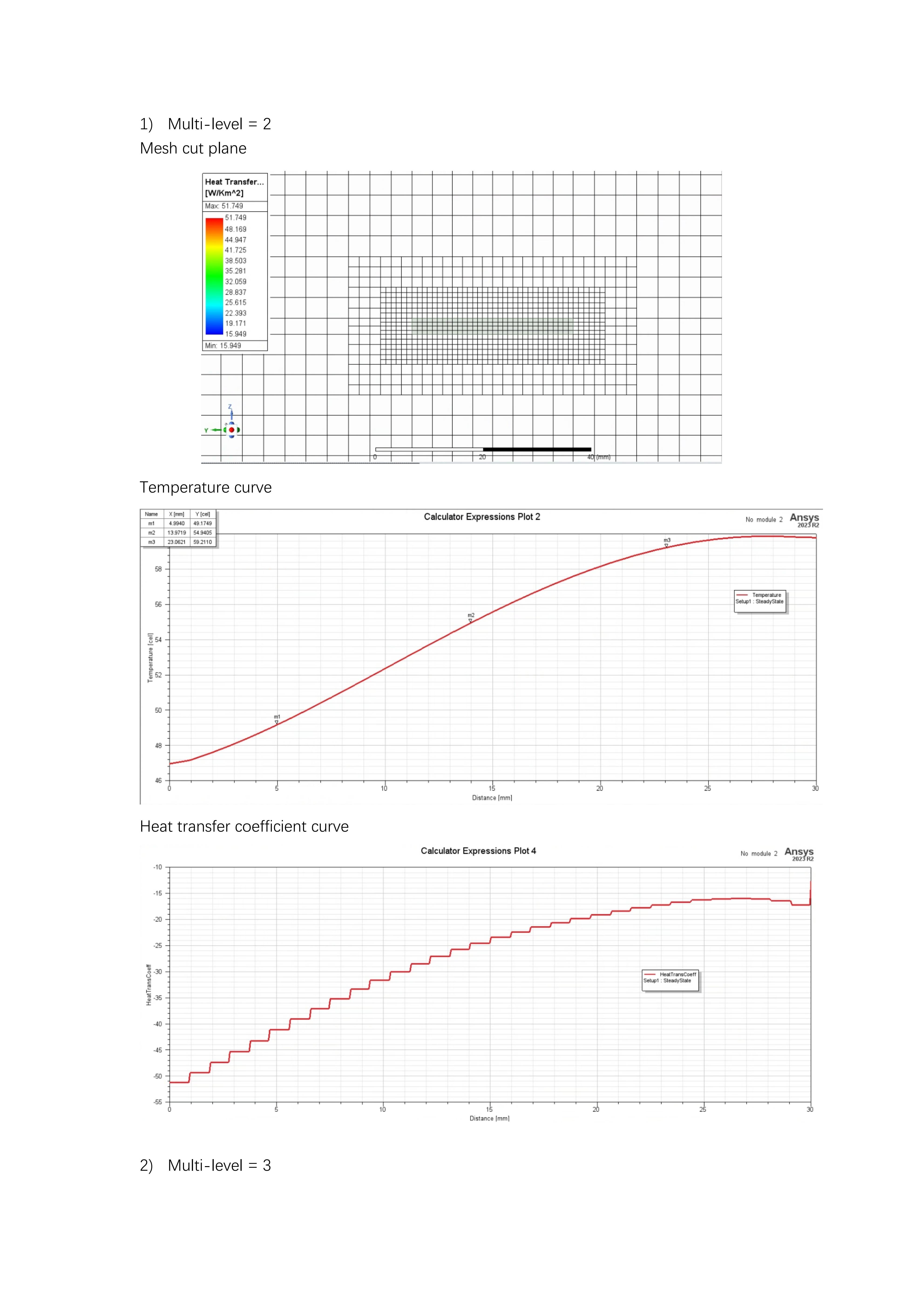

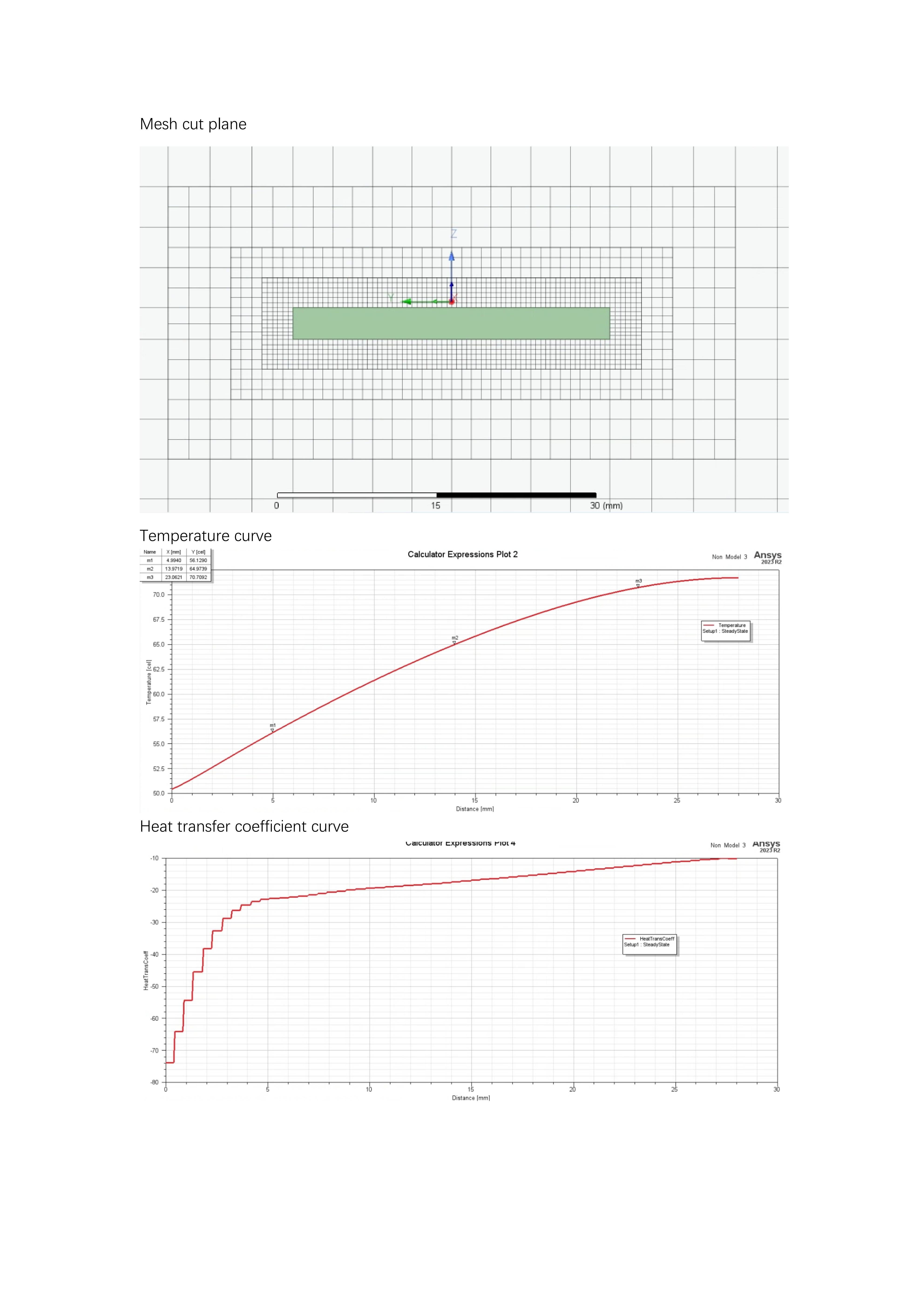

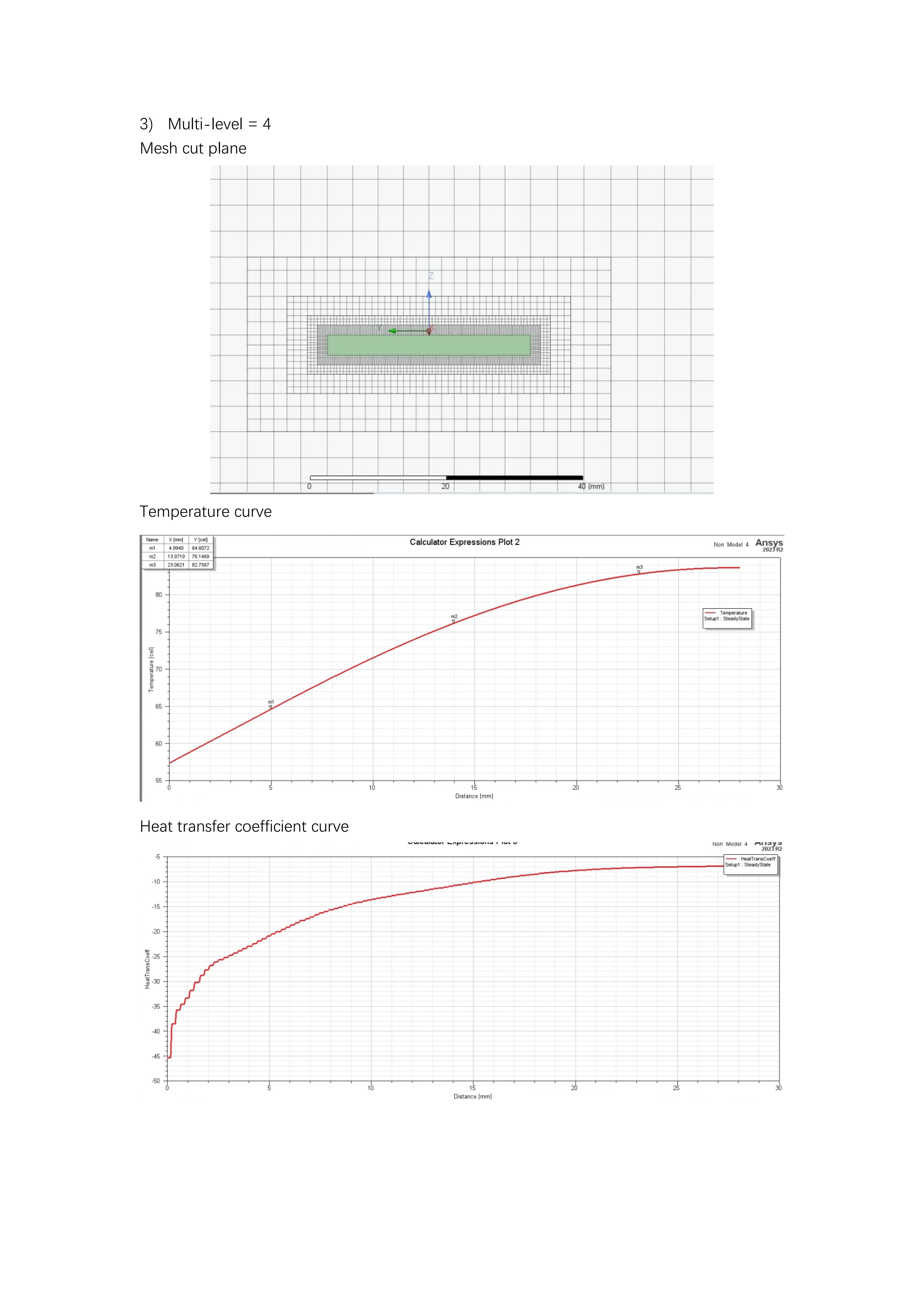

SubscriberI’m simulating a heating source placed in a wind tunnel by AEDT icepak. The air speed in the tunnel is set to 1.5 m/s. To reduce the total cell count, I created a separate mesh region (assembly) around the heating source. In addition, I applied a local mesh refinement operation on the heating source itself. Based on the Reynolds number, I selected a laminar flow model. However, I found that the “multi-level” mesh setting has a large influence on the simulation results. Please see the attached results.

I don’t have a strong background in fluid mechanics, so I’m not sure if I’m handling the mesh correctly for this kind of laminar flow problem. For such a relatively simple laminar case, I expected that a finer mesh would always give more accurate results. But according to my rough hand calculations, when I set Multi-level = 4, the predicted temperature is actually higher than expected. In my future work there will be some small objects mounted on the plate, so I will probably need to use Multi-level = 4 in the model to resolve the geometry. Do you have any recommendations on how to set up the mesh properly for this type of laminar flow simulation?

-

December 19, 2025 at 2:03 pm

Essence

Ansys EmployeeHello,

This happens when the mesh is not refined adequately. Therefore, I would suggest you to conduct grid independence test.

-

- You must be logged in to reply to this topic.

-

4623

-

1535

-

1386

-

1215

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.