TAGGED: gear

-

-

September 1, 2022 at 6:43 pm

-

September 2, 2022 at 7:23 am

Florian.CHANCEL

SubscriberHello,

I have done this type of calculation before, with simple gear or planetary gear.

If you just want a simple rotation, you can add a remote displacement in the boundary conditions, and release the rotation DOF.

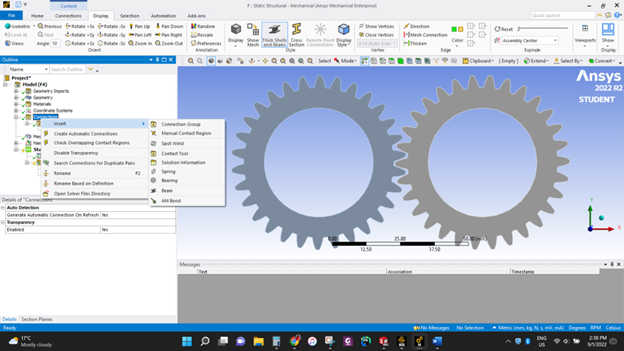

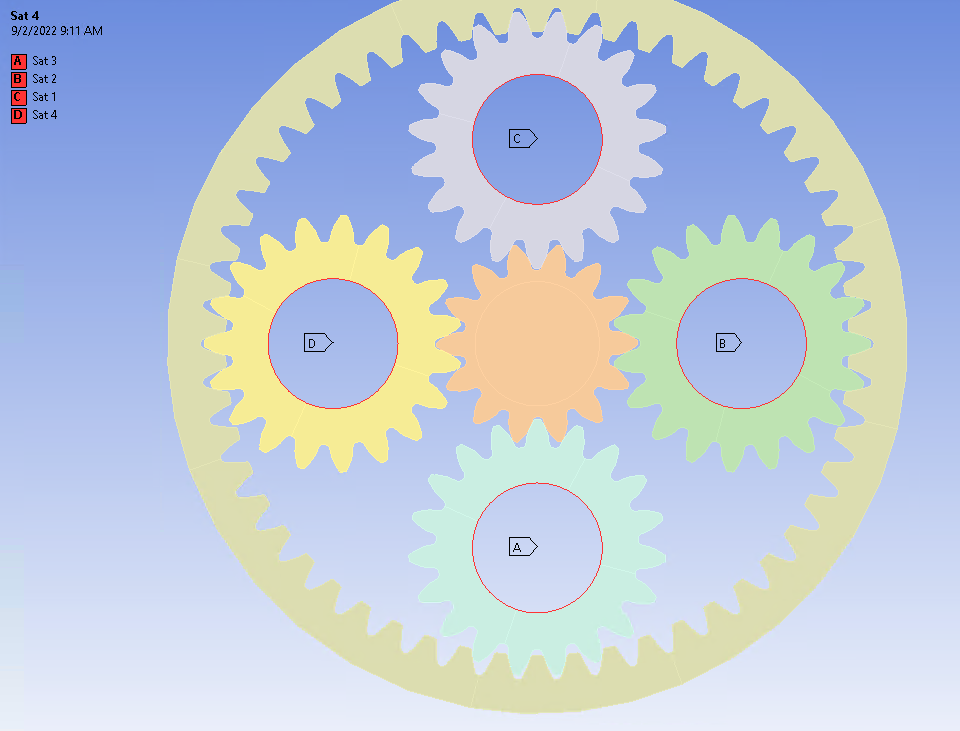

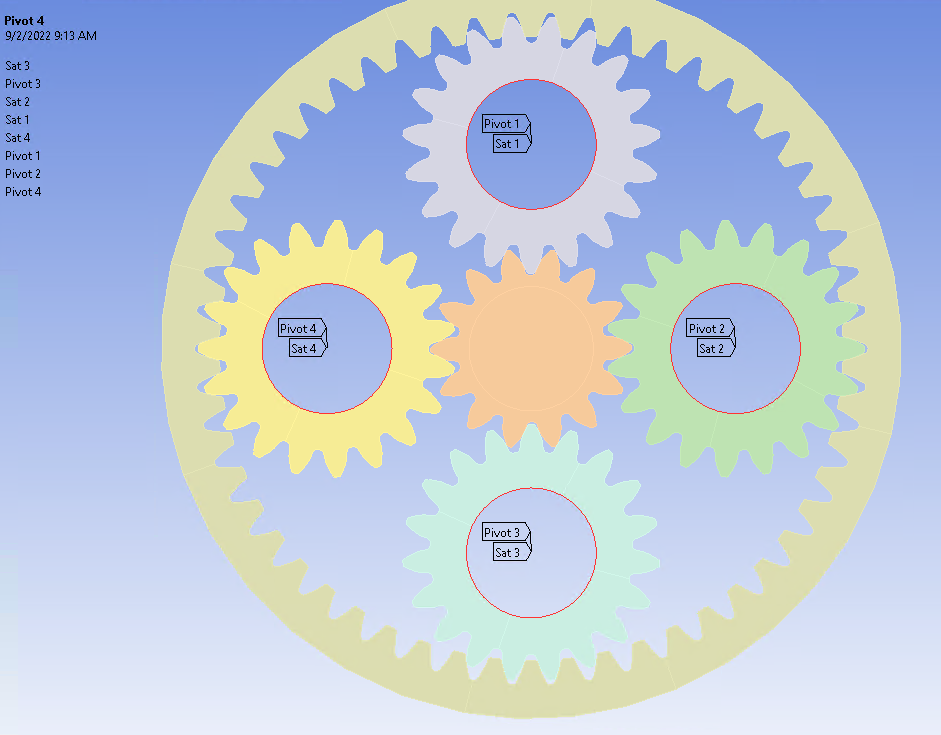

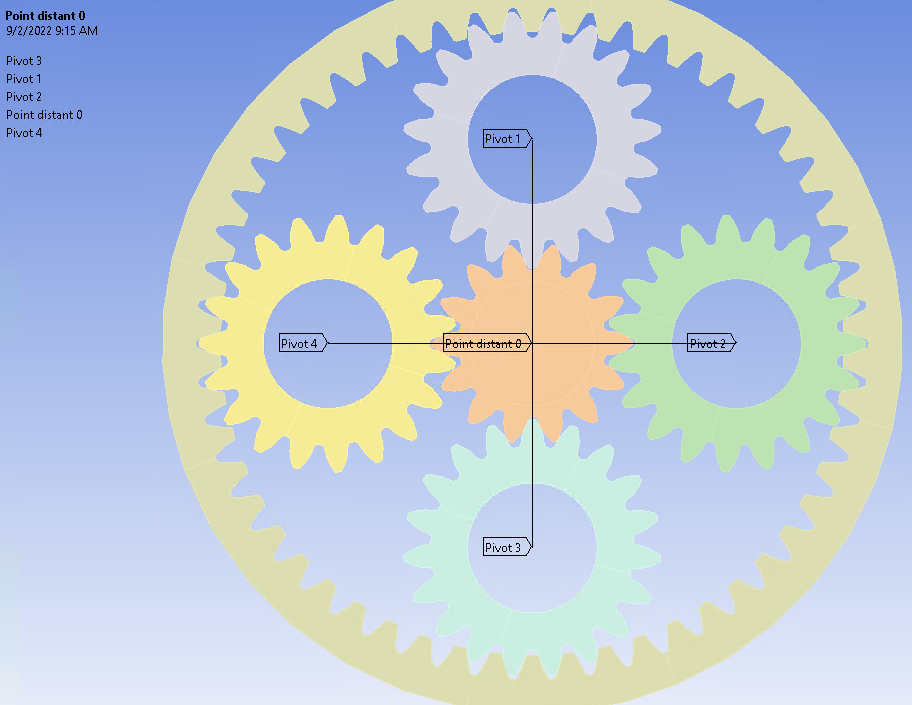

If you want a coupled rotation for instance like the satellite displacement, it's more complexe :Firstly, I defined Remote points of the satellite's center

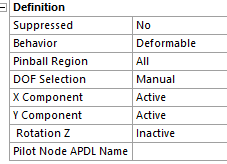

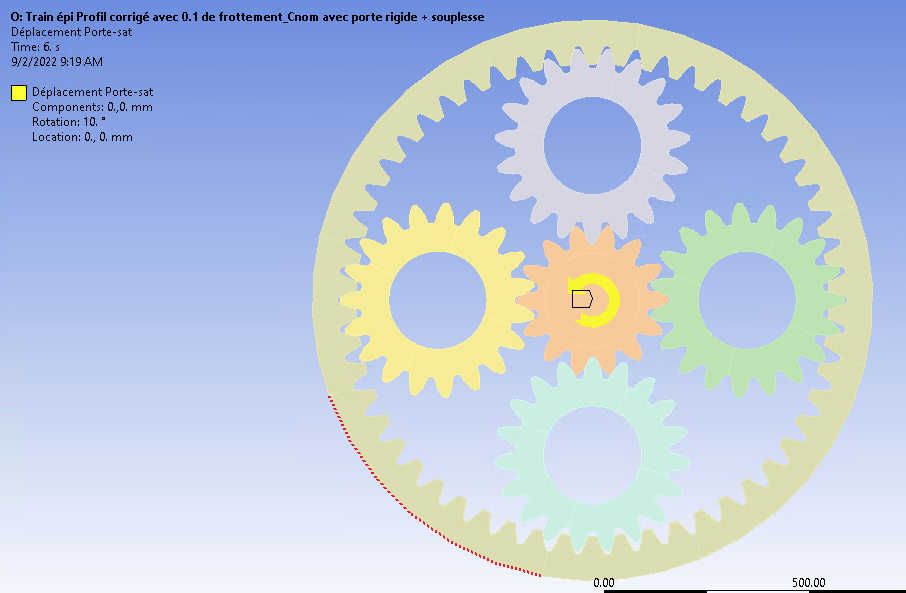

And I defined their DOF

Secondly, I defined a "bearing remote point" of the remote point created before

And I defined their DOF

In a third step, I defined a distant point corresponding to the center of rotation of the planet holder

And I defined its DOF

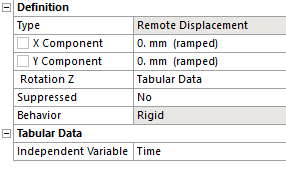

And finaly, I defined a remote displacement of this last remote point, in the boundary conditions

To controle the rotation DOF

Maybe, this process could have been less complex.

I hope this will help you,

Regards,

Florian C.

-

September 6, 2022 at 1:10 pm

fab88

SubscriberThank you for Florian,

I'm working on a simple rotation.

I'm going to try as you suggested.

I will come back with my results.

Thank you again.

-

September 16, 2022 at 5:36 pm

fab88

SubscriberHello, Florian!

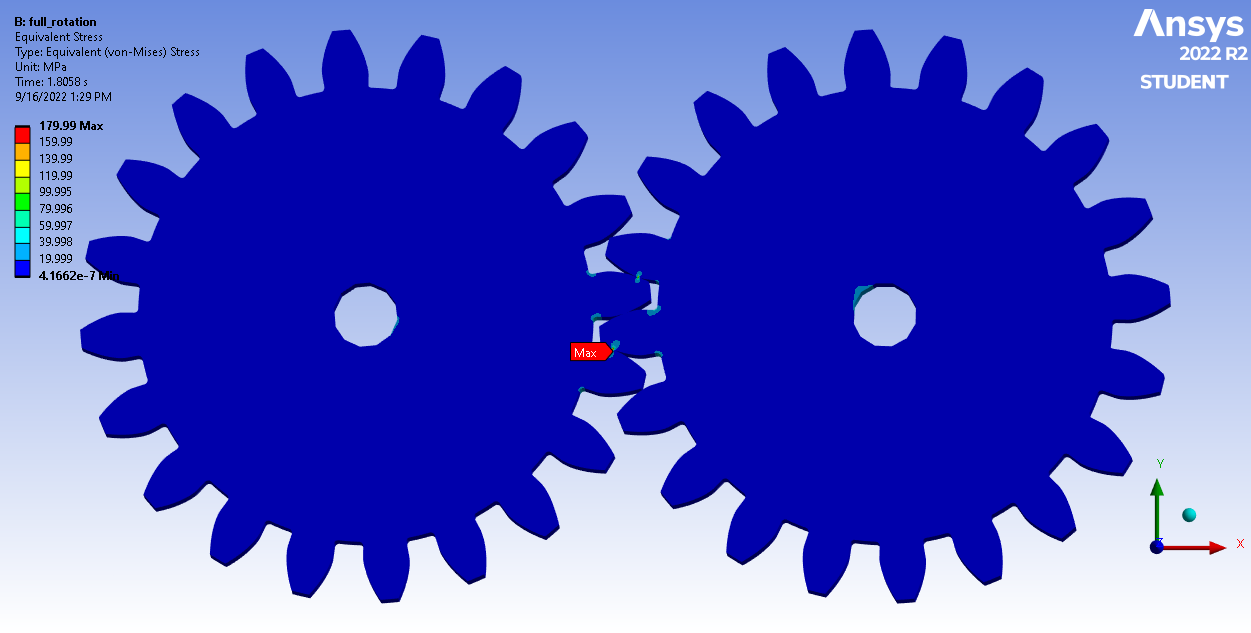

I have managed to successfully run the 2D model.

Thank you for your guidance.

Now, I am trying to reduce the computation time and improve the accuracy by using a simulating frictional model of the gear instead of the full gear.

However, it seems my boundary conditions are giving me trouble.

Do you have any guidance on how I should proceed?

I am attaching a link to my archive file (https://drive.google.com/file/d/1onwLXCv5wEWG3J-OHG6lB1HRL5rP8Sm_/view?usp=sharing ) for your review.

Thank you

-

September 19, 2022 at 11:25 am

Florian.CHANCEL

SubscriberI cannot open you project.

I think you sent me the wrong file. It's not the archive file.

Can you try again ?The frictional contact between your teeth must have a "close statut" at the beginning of the calculation otherwise it will not converge.

I don't see your mesh, but you can compute an inflation to have accurate results.

-

September 19, 2022 at 6:50 pm

fab88

SubscriberSorry,

I come to realize that I attached the wrong file.

The initial contact status is closed.

Here is the correct file.

Thank you.

-

September 20, 2022 at 6:01 am

Florian.CHANCEL

SubscriberI cannot open your file because it's an older version than I have(I use 2021R1).

Can-you try to explain your boundary conditions, your load cases, your mesh and connexion details ? -

September 21, 2022 at 7:53 pm

fab88

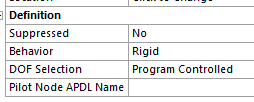

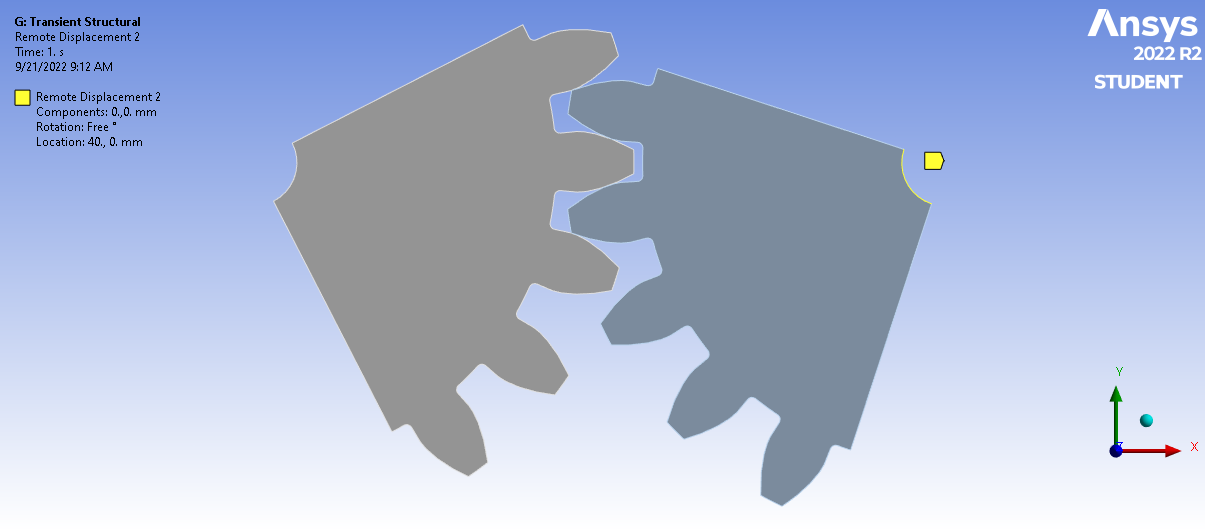

SubscriberActually, I had forgotten to apply a remote displacement on the driven gear. But now, it is working.

Here are my BCs.

Also, I had to include in weak springs to avoid rigid body motion.

Now, I am facing another problem. When I am trying to allow full rotation (360) of the cut gears, the solution fails to solve. Let's say, I want 10 revolutions.

I mean after this time.

What can I do?

Thanks.

-

September 22, 2022 at 6:10 am

Florian.CHANCEL

SubscriberOk, you have to set up some steps to help the static calculation

Step 1 : You lock (0°) the rotation of the left pinion, and apply the torque on the right pinion.Step 2 : you rotate the left pinion (for example 10°) => In this step, you have to set up sub step every 1°(or more) => Substeps are the key to the convergence. Your calculation have to stay in static, if the rotation gap is to big, calculation will fail

Advice 1 : You should fixe your remote point on the two cut edges of your pinion and set up the rigid behavior

Advice 2 : turn on "large displacement"

Advice 3 : Weak springs are not a problem, you just have to check if the reaction forces are near 0 N after your calculation.

Advice 4 : 360° is not useful, I think juste a rotation on 3 teeth are good enough to capture all results.

Can you show your mesh, can you send me CAD file in .step ?

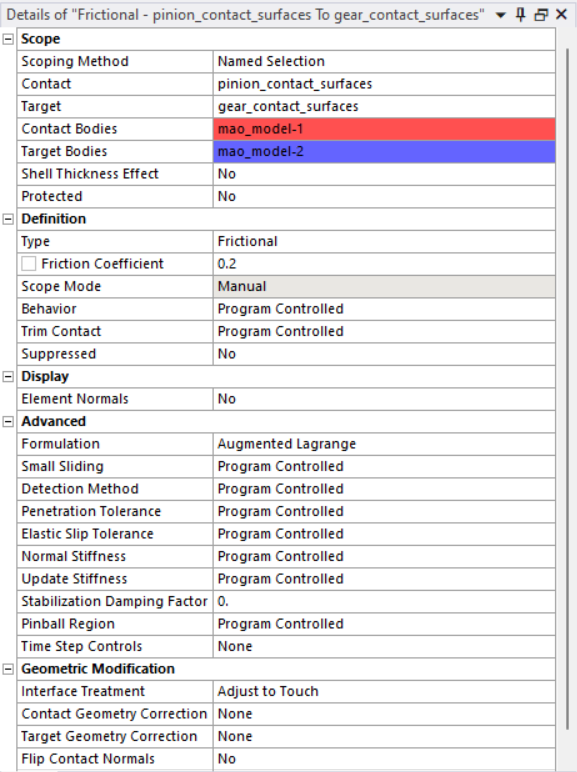

Can you show me the parameters of your frictionnal contact ?

-

September 22, 2022 at 6:15 am

Florian.CHANCEL

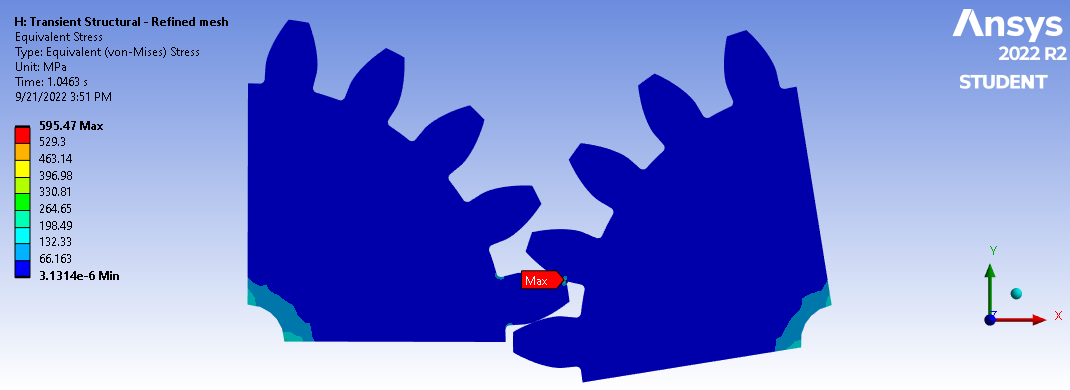

SubscriberOk, I also understood something thanks to your pictures.

The rotation of your left pinion is counterclockwise => Therefore, after 1.0463 sec, as you can see, you have the last contact point on the last teeth. So there is no anymore teeth to keep the input torque ! I think your calculation fail because of this.

ou cannot have 360° or 10 revolutions because you have only 1/4 of your pinion.

-

September 22, 2022 at 2:23 pm

fab88

SubscriberThe project that I am working on consists of calculating displacements/ stresses and temperatures. It is a transient thermomechanical analysis. Therefore, I need to have more revolutions to get to a stable temperature. Young's modulus is a function of temperature. In order to reduce the computation time, I cut the gears into quarters.

The calculations I was doing are preliminary (Transient structural analysis)

The torque on the left gear (driven gear) is an output torque.

The remote displacement on the pinion is equivalent to a constant angular velocity.

Here are my frictional contact details

Here is my CAD file.

Thank you again.

-

September 27, 2022 at 3:51 pm

fab88

SubscriberHello Florian,

I'm still stuck.

Have you found a way to have a full revolution?

Thank you.

-

September 28, 2022 at 5:28 am

Florian.CHANCEL

SubscriberHello Fab,

I don't really understand what you want. If you need a complete revolute of your pinions, you have to represent the complete pinions, and not a quarter, right ?

If you import your transient thermal calculation, maybe you can split the input time in different static calculation ? in this way, you may cover temperature with different 1/4 of model ?

-

September 28, 2022 at 1:24 pm

fab88

SubscriberI am going to do full gears and a coarse mesh to the region of less interest.

Thank you again.

-

- The topic ‘Spur gear stress analysis’ is closed to new replies.

-

3472

-

1057

-

1051

-

934

-

902

© 2025 Copyright ANSYS, Inc. All rights reserved.