-

-

June 21, 2023 at 11:11 am

agambhir_be20

SubscriberHi

Im trying to do fibre push out simulations in ansys. The fibre and the matrix are of SiC material bonded by czm contact debonding. I have made the model in micrometers. When I try to run tyhe simulation, after sometime it gives me this error, I've tried increasing the substeps but result is still the same. Can anyone help me regarding this as I'm new to this domain.

-

June 23, 2023 at 6:10 pm

mrife

Ansys EmployeeHi agambhir_be20

How many allowed substeps are defined? Is this being run as a large deformation analysis? Have you double checked the CZM properties? You may want to run a simple two element (like two cubes meshed each with just one element) test to make sure the debonding is defined as you expected. A simple typo could result in the debonding being too strong...I've made that mistake plenty of times to know!

Mike

-

June 26, 2023 at 9:02 am

agambhir_be20

SubscriberHi Mike,

Thank you for responding,

I gave the displacement of 5 micrometers with large deflection being turned on. I have checked the czm properties. I have defined about 300 steps, initial substeps-100,with max substeps 300.

What do you mean by simple two element test? Sorry for the doubt coz I'm new to this software and don't know much about this.

Akshit

-

June 26, 2023 at 1:26 pm

mrife

Ansys EmployeeHi Akshit

I mean literally a two element test. CAD model 2 cubes with 2 touching faces. Mesh each with one element. Define the CAM bonded contact between them. Apply BC and load, then post-process to determine whether they pull apart per the CZM material definition or not.

-

June 26, 2023 at 1:40 pm

mrife

Ansys EmployeeBTW to test a material model on a simplified FEM is fairly standard in the FEA community. Other examples include simulating a dog-bone specimen when implementing a metal plasticity model for the first time. Or a one element cube when implementing a hyperelastic material - it's really easy to set up the different loading conditions on a single element i.e. tension, shear etc.

-

June 26, 2023 at 2:10 pm

agambhir_be20

SubscriberI did that I guess. The fibre was sliding over the matrix but it was getting deformed from the bottom which I certainly don't want. I have attached the pictures of that simulation, I think that should be the equivalent to two element test.

Should I make any change in the initial model which is giving me errors?

Also is there any ansys manual where the czm properties of BN interface is given so that I can double check the properties.

Thanks for your help

Akshit

-

June 29, 2023 at 10:15 am

-

June 29, 2023 at 3:22 pm

mrife

Ansys EmployeeHi agambhir_be20

See the MAPDL Help -> Material Reference -> Chapter 4.20.6 on CZM material for Contact. If you are on the Student version you should be able to open the help from Mechanical.

The 'Mode' is the type of separation; mode 1 is normal to the interface while 2 is slip tangential to the interface (which your model seems to be, please correct me if I am wrong). 3 is a mix.

-

July 4, 2023 at 11:27 am

agambhir_be20

SubscriberHi Mike

I made some changes in the model,

I chose mode 2 in separation-distance based debonding for czm properties.

Calculated the max eq tangential contact stress by F/A. The max force I want is 56mn and calculated area of the fibre surface on which I applied displacement.

Tangential slip at completion of debonding I just took from an experiment ( still don't know if I should change it or not).

I got these results with the changes I made.

I gave 0.9 um displacement to the fibre in negative Y direction.

Now I want to add stiffness to the bond and I want the fibre to slide after the bond breaks. How can I do that? Because the fibre goes back to the original position after the displacement is 0.

Also the methodology I followed now, is this in the right direction?

Thanks for your help

Akshit

-

July 5, 2023 at 2:47 pm

mrife

Ansys Employeeagambhir_be20 can you show the applied displacement - setting it to zero means go back to the original location i.e. no displacement. From the latest picture it looks like the bond is breaking at the 'top' (most positive Y location) of the fibre. It seems like you are going in the right direction.

Mike

-

July 7, 2023 at 9:11 am

agambhir_be20

SubscriberHi Mike

Now I gave the displacement a bit more (0.75 um) than the max tangential slip which I filled in the czm properties (0.68um). Now the fibre pushes out suddenly around this displacement. So now its working fine but the equivalent stress which I'm getting is more than the max tangential stress which I filled in the czm properties ( calculated by F/A in which I want max force to be 56mn). So is there any way I get it right?

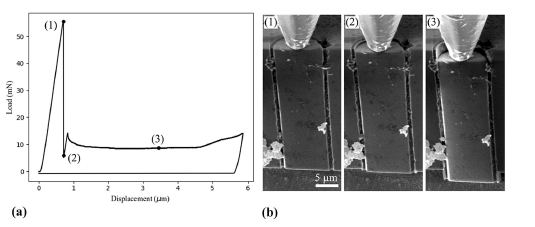

Here is the graph of the experiment that I'm following, and I made my model accoding to the experimental dimentions.

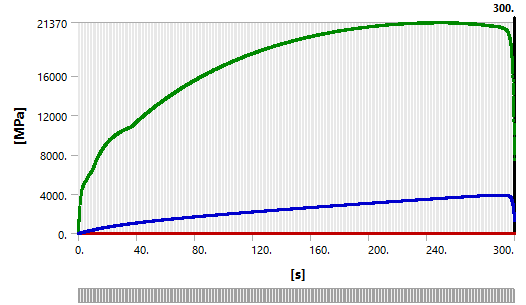

And this is the stress I'm getting

Here are the czm properties which I used

-

July 7, 2023 at 2:40 pm

mrife

Ansys EmployeeHi agambhir_be20

Comparing equivalent stress (of whole body?) to max tangential contact stress as defined in CZM? Try comparing the contact result tangential stress to material definition. Or did I misunderstand?

-

July 13, 2023 at 1:31 pm

agambhir_be20

SubscriberHey Mike,

I'm trying to plot the load vs displacement graph and want to compare it with the experimental one that I have posted above. In the exp, the load at which the fibre breaks is around 56-57mN. Now in experiment I gave separation distance based debonding in CZM and gave max tangential slip at the completion of debonding according to the experiment graph (the bond breaks at 57mN , so took displacement of that point which is 0.7um). How do i calculate max tangential contact stress? is F/A the correct way? (F being 56mN and Area of the fibre surface on which I applied displacement).

Because the result which I'm getting now, the force at which the fibre breaks is 7-8 times higher than the experiment one.

-

- The topic ‘Solution not converging ( Fibre Push Out )’ is closed to new replies.

-

3467

-

1057

-

1051

-

929

-

896

© 2025 Copyright ANSYS, Inc. All rights reserved.