TAGGED: contact, element-distortion, shell

-

-

September 21, 2023 at 1:22 pm

Noah

SubscriberHello,

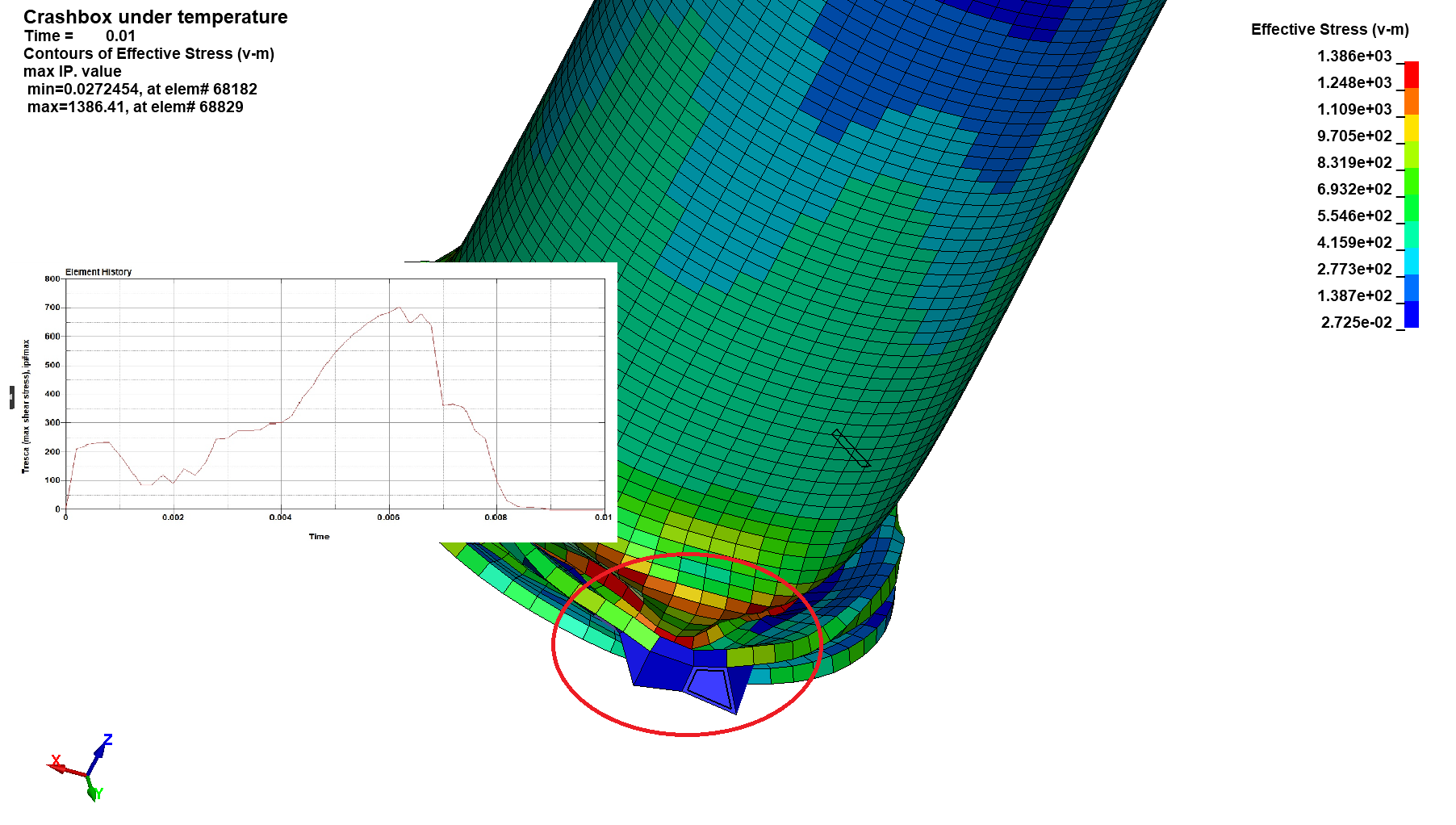

I am simulating the deformation of a metallic tube in the low velocity range.

Unfortunately, large distortions occur at the shell elements (see figure).

These stretch to infinity and the voltage drops to 0.

These distortions occur during self-contact.

Attempts to counteract this by applying Hourglass were not really successful.A short excerpt from the K-File:

*CONTROL_HOURGLASS

$# ihq qh

8 0.03

*CONTROL_SHELL

$# wrpang esort irnxx istupd theory bwc miter proj

20.0 1 -1 0 16 2 1 0

$# rotascl intgrd lamsht cstyp6 thshel

1.0 0 0 1 0

*CONTACT_AUTOMATIC_SINGLE_SURFACE_ID

$# cid title

1Self_Contact

$# surfa surfb surfatyp surfbtyp saboxid sbboxid sapr sbpr

13 0 3 0 0 0 0 0

$# fs fd dc vc vdc penchk bt dt

0.2 0.18 0.0 0.0 5.0 0 0.01.00000E20

$# sfsa sfsb sast sbst sfsat sfsbt fsf vsf

2.0 1.0 0.0 0.0 1.0 1.0 1.0 1.0

$# soft sofscl lcidab maxpar sbopt depth bsort frcfrq

1 0.2 0 1.025 3.0 2 100 1

$# penmax thkopt shlthk snlog isym i2d3d sldthk sldstf

0.0 1 2 0 0 0 0.0 0.0

$# igap ignore dprfac dtstif edgek unused flangl cid_rcf

1 0 0.0 0.0 0.0 0.0 0

*CONTACT_AUTOMATIC_SURFACE_TO_SURFACE_ID

$# cid title

2dropmass

$# surfa surfb surfatyp surfbtyp saboxid sbboxid sapr sbpr

13 10 3 3 0 0 2 0

$# fs fd dc vc vdc penchk bt dt

0.2 0.18 0.0 0.0 0 0.01.00000E20

$# sfsa sfsb sast sbst sfsat sfsbt fsf vsf

1.0 1.0 0.0 1.0 1.0 1.0 1.0

$# soft sofscl lcidab maxpar sbopt depth bsort frcfrq

2 0.1 0 1.025 1.0 2 10 1

$# penmax thkopt shlthk snlog isym i2d3d sldthk sldstf

0.0 0 0 0 0 0 0.0 0.0

$# igap ignore dprfac dtstif edgek unused flangl cid_rcf

1 0 0.0 0.0 0.0 0.0 0

*CONTACT_AUTOMATIC_SURFACE_TO_SURFACE_ID

$# cid title

3bottom

$# surfa surfb surfatyp surfbtyp saboxid sbboxid sapr sbpr

13 11 3 3 0 0 0 0

$# fs fd dc vc vdc penchk bt dt

0.2 0.18 0.0 0.0 0 0.01.00000E20

$# sfsa sfsb sast sbst sfsat sfsbt fsf vsf

1.0 1.0 0.0 1.0 1.0 1.0 1.0

$# soft sofscl lcidab maxpar sbopt depth bsort frcfrq

2 0.1 0 1.025 1.0 2 10 1

$# penmax thkopt shlthk snlog isym i2d3d sldthk sldstf

0.0 0 0 0 0 0 0.0 0.0

$# igap ignore dprfac dtstif edgek unused flangl cid_rcf

1 0 0.0 0.0 0.0 0.0 0Maybe someone has an idea why this happens?

-

September 23, 2023 at 5:08 am

Ushnish Basu

Ansys EmployeeWhile we cannot comment on a specific model, I would suggest in general to make sure you don't have overlapping contacts. You may also find these recommendations helpful:

https://www.dynasupport.com/howtos/material/negative-volume-in-soft-materials

-

September 25, 2023 at 10:24 pm

Noah

SubscriberI have tried several methods. So far, I have only been able to solve the problem by modeling the floor geometry as a rigid wall. So it seems to be due to overlapping contact formulations. Is there any other possible solution for overlapping contacts?

Greetings

-

September 25, 2023 at 10:49 pm

Ushnish Basu

Ansys EmployeeYou can either use one single-surface contact, or define your contacts carefully so the contact surface pairs don't overlap

-

- The topic ‘Shell Element with large distortions’ is closed to new replies.

-

5094

-

1830

-

1387

-

1248

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.