-

-

March 1, 2023 at 6:42 am

Sushil Sharma

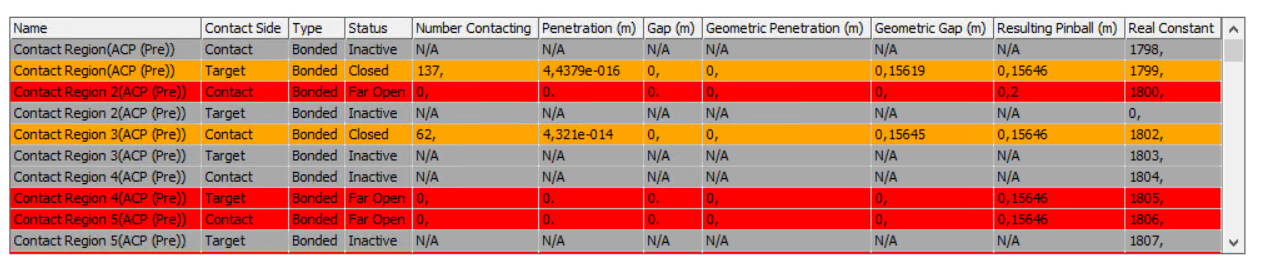

SubscriberI am trying to perform a static analysis of a wind turbine blade. I used share topology for the common joint line of the sections I used to model the blade. When I try to do the static analysis, it shows the joint status as far open. How can I solve this issue? I wanted to resolve it using a pinball radius, but it didn't work. Here attached the blade 3D and joint information table.

-

March 1, 2023 at 2:09 pm

Ashish Khemka

Forum ModeratorHi Sushil,

Can you remove the regions that are already sharing topology from the region of contact? Regions that are already sharing the topology need not be included in contact definition.

Regards,

Ashish Khemka

-

March 1, 2023 at 3:43 pm

Sushil Sharma

SubscriberThank you

If that's the case, then why does the program automatically generate the contact region? In my case I use shared topology to share the common edge, Does that mean I didn't have to assign any contact definition?

-

March 1, 2023 at 4:15 pm

-

March 2, 2023 at 1:40 pm

Sushil Sharma

SubscriberCan we do the convergence study of the composite ACP(pre-preg) model? I assigned the layup information and did the static analysis, and tried to study the convergence in deflection output, but it did not offer the convergence tool. I tried changing the material to aluminium, and it worked. Please explain why the convergence tool doesn't work for a composite material assignment.

Thank you

-

March 2, 2023 at 2:18 pm

peteroznewman

SubscriberHow will knowing why the convergence tool doesn't work help you?

-

March 2, 2023 at 3:02 pm

Sushil Sharma

SubscriberI want to check whether the outputs are within the convergence limit. I tried it following the adaptive convergence tutorial, but in my case (material defined as composite ACP), there isn't a convergence tool to track the refinement. When I use the same model (with homogeneous material), I can use a convergence tool. How can I perform a convergence study of my model with material as ACP composite? Is there any separate way for composite material?

Thank you

-

March 2, 2023 at 4:52 pm

peteroznewman

SubscriberYou can do a convergence study manually by using Mesh Sizing controls to set the element size in the neighborhood of the peak stress. Solve the model four or five times to get four or five points on a Peak Stress vs Element Size chart.

The element size changes should have a constant ratio. A good ratio is between 1.5 and 2.0

For example, using a ratio of 2.0, if your initial element size was 1 m then you would remesh to get a series of models at element sizes of 1.0, 0.5, 0.25 and 0.125 m.

-

- The topic ‘Shared topology and connection status far open’ is closed to new replies.

-

3487

-

1057

-

1051

-

955

-

922

© 2025 Copyright ANSYS, Inc. All rights reserved.