-

-

March 1, 2024 at 8:27 pm

-

March 4, 2024 at 1:24 pm

Ram Gopisetti

Ansys EmployeeHi javat,

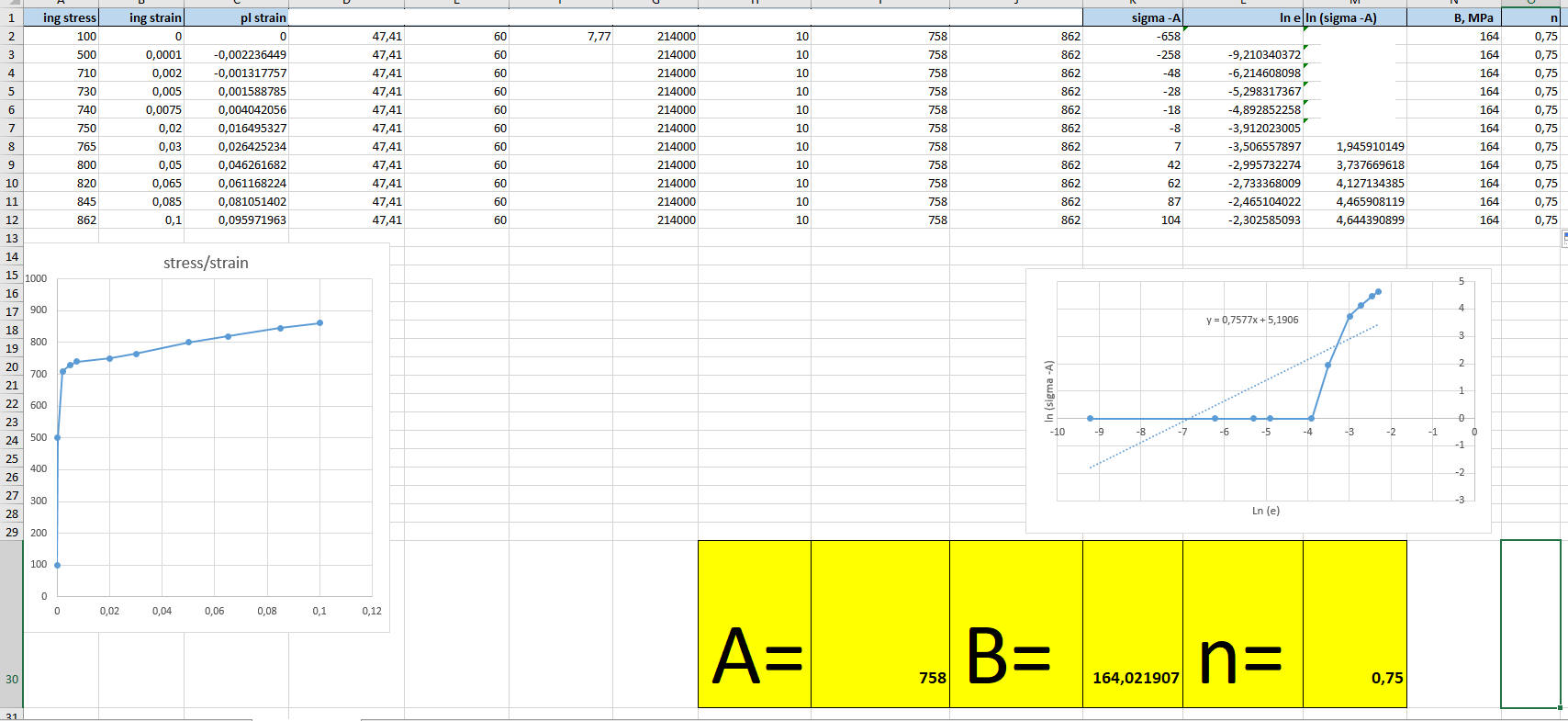

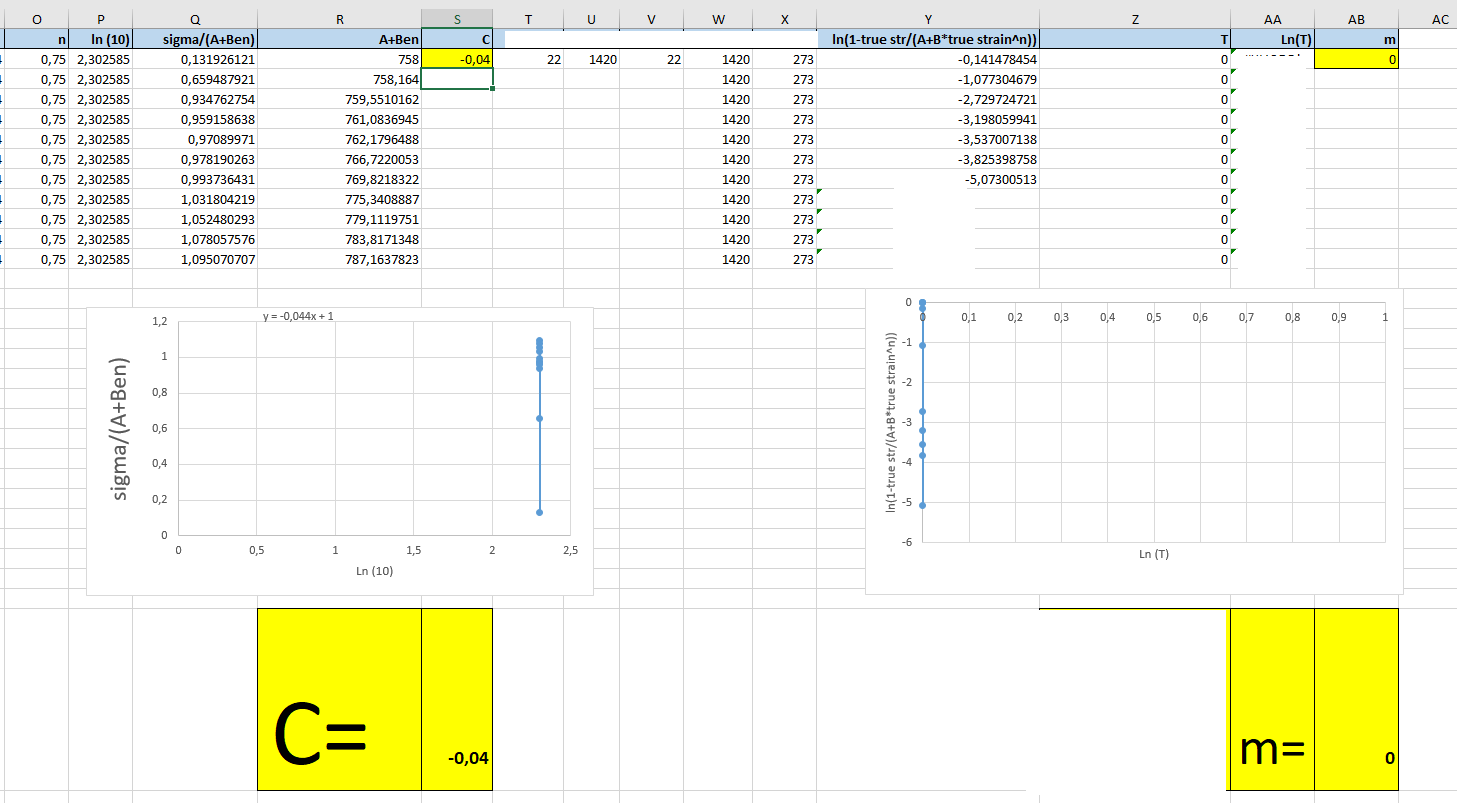

Are you sure you have calibrated the damage variables correctly from the test data?

I am not sure if you can equate the damage variables directly to the JC main model coefficient can you check if the reference you had is from a proper source? A is inherently a yield point and reaching such of level of damage is unusual and incorrect to work.

Check the following YouTube link for the calibration of the JC correctly with strain rate cases.

https://www.youtube.com/watch?v=F8BQNm-zYSM

https://www.youtube.com/watch?v=vRTgY1HikUQ

Cheers, Ram

-

March 4, 2024 at 4:16 pm

javat33489

SubscriberYes sir, it was from these videos that I made the Johnson Cook models.

-

-

March 5, 2024 at 6:46 pm

Bernd Hochholdinger

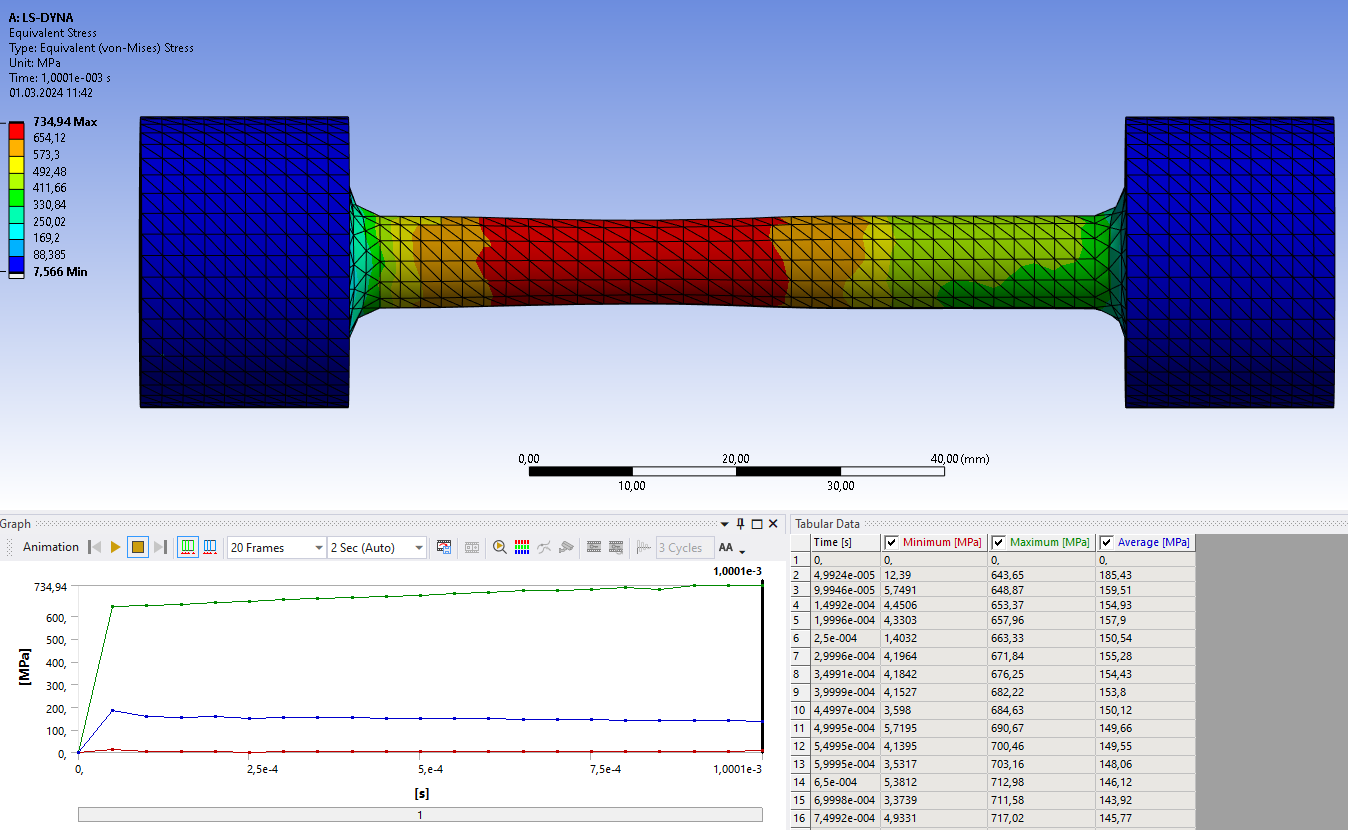

Ansys EmployeeHave you checked the evloution of the according damage history variable of your Johnson Cook model.

The meaning of History Variables for certain material models can be found here:

https://www.dynasupport.com/howtos/material/history-variables

History Variables can be output to d3plot via Parameter NEIPH for solid element in the Keyword *DATABASE_EXTENT_BINARY.

Cheers,

Bernd

-

- The topic ‘Sample rupture in LS-Dyna ACT’ is closed to new replies.

-

3567

-

1103

-

1063

-

1045

-

947

© 2025 Copyright ANSYS, Inc. All rights reserved.