-

-

December 11, 2024 at 6:34 am

saransh.verma2810

SubscriberI am conducting a TIG welding analysis to calculate residual stress.

first i calculated Temperature in transient thermal using convection, radiation and moving heat source.

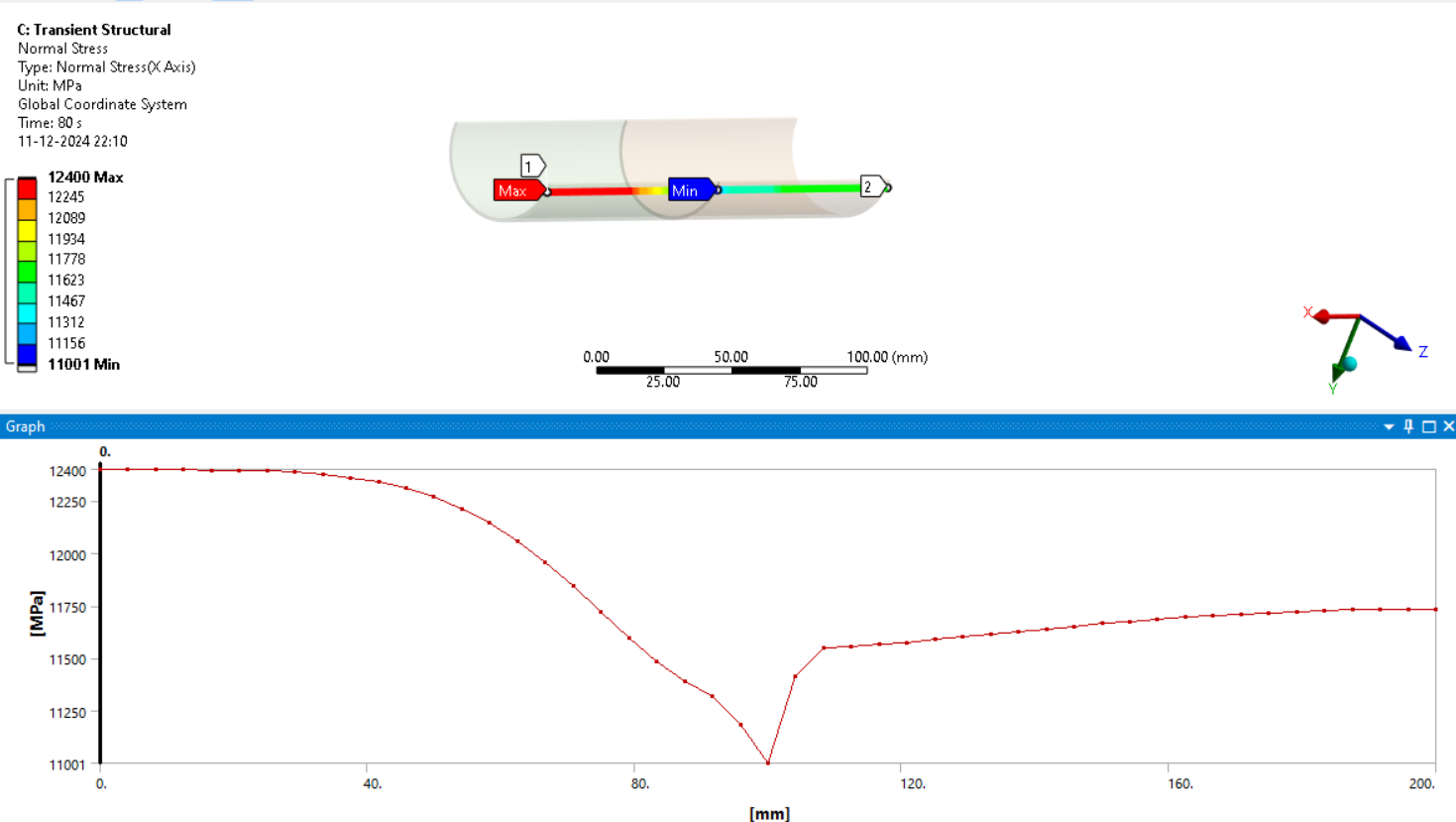

Then this temperature was used a input in transient structural to calculate residual stress using fixed support as boundary condition.The graph of stress only shows tensile stress but not compressive stress.But residual stress do have compressive stress

How can i correct it

-

December 11, 2024 at 3:26 pm

dlooman

Ansys EmployeeResidual stress requires path-dependent nonlinear material properties (plasticity) and the elevated stress free temperature of the molten material. The effect of molten material cooling is almost entirely tensile, so your result doesn't surprise me too much. Are you plotting a signed quantity like SX or an unsigned quantity like SEQV?

-

December 11, 2024 at 3:41 pm

saransh.verma2810

SubscriberI am plotting Equivalent (von-Mises) Stress vs length

and the properties of materials are as followed

-

December 11, 2024 at 3:46 pm

dlooman

Ansys EmployeeSince equivalent stress is unsigned you may be incorrectly assuming the stress is tensile. You can't identify whether the stress is tensile or compressive with SEQV. The material properties are good, but you still need to specify an elevated stress-free temperature for regions where the material has become molten.

-

December 11, 2024 at 3:51 pm

saransh.verma2810

SubscriberWhere can I add elevated stress free temperature where material has become motlen like where can i find it in engineering data

and which stress type should use to get desired results -

December 11, 2024 at 3:57 pm

dlooman

Ansys EmployeeIn the details for the body you can specify the "Reference Temperature." A "Normal Stress" like SX, SY or SZ would be signed.

-

December 11, 2024 at 4:09 pm

-

December 11, 2024 at 4:13 pm

dlooman

Ansys EmployeeIt's not an exact science, but a temperature at which the molten material begins to have some strength. If you don't taken into account the elevated reference temperature you are just applying a thermal expansion load which will naturally produce compression. Are both ends of the pipe fixed in real life?

-

December 11, 2024 at 4:15 pm

saransh.verma2810

SubscriberHow can i take elevated reference temperature like from where should i add it

and the ends of pip are fixed -

December 11, 2024 at 4:41 pm

-

- You must be logged in to reply to this topic.

-

3467

-

1057

-

1051

-

918

-

896

© 2025 Copyright ANSYS, Inc. All rights reserved.