-

-

December 1, 2023 at 12:52 pm

jfonken

SubscriberHi all,

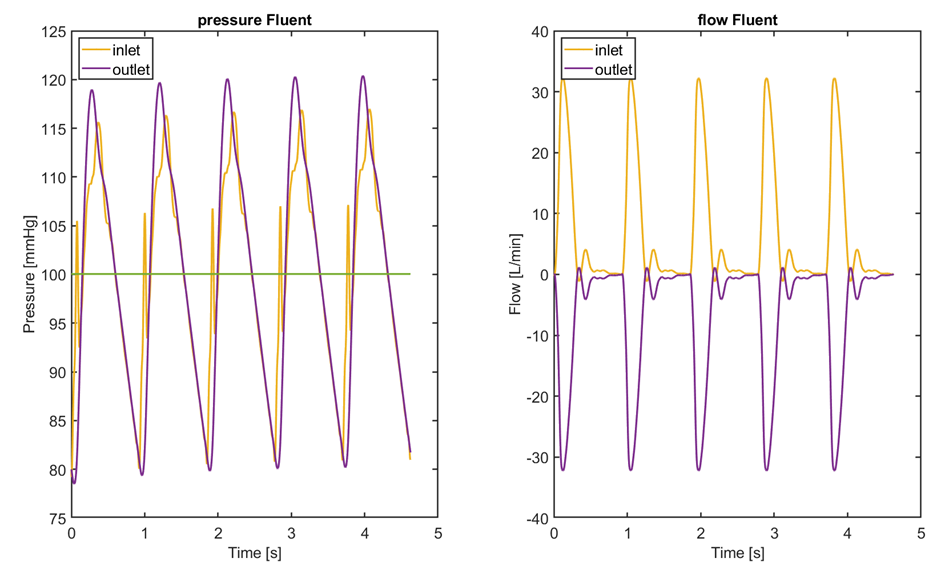

I have a straight tube with a length of 10 cm and a diameter of 2 cm (simple representation of a vessel). At the inlet, I prescribe a patient specific inlet velocity and at the outlet I have a 3 element windkessel model. I tuned the WK parameters in such a way that outlet pressure is between 80 and 120 mmHg (10000/16000 Pa). However, I get these ‘spikes’ in pressure. My timestep was 1 ms, I am using the PISO pressure-velocity coupling method and I chose laminar flow.

What we already tried:

- Lower the peak flow, this decreases the spikes suggesting that the difficulties mainly arise when the change in flow rate (increase or decrease) is large.

- Lower the timestep, this did not change the results.

- Decrease the mesh size, again no change in results.

- Tried pseudo-time method, no change in results.

Adapt the WK parameters. Decreasing the compliance seems to improve the results, but then I did not get physiological pressures.

- We're kind of lost now :(

- Do any of you have suggestions on how to tackle this problem?

-

December 5, 2023 at 2:47 pm

Essence

Ansys EmployeeHello,

Can you please show the inlet and outlet BCs? Maybe what and how exactly you applied at the BCs?

-

- The topic ‘Pressure ‘spikes’ at inlet in straight tube under large, laminar flow’ is closed to new replies.

-

4678

-

1565

-

1386

-

1242

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.