-

-

July 31, 2023 at 5:52 am

skimura

SubscriberHello

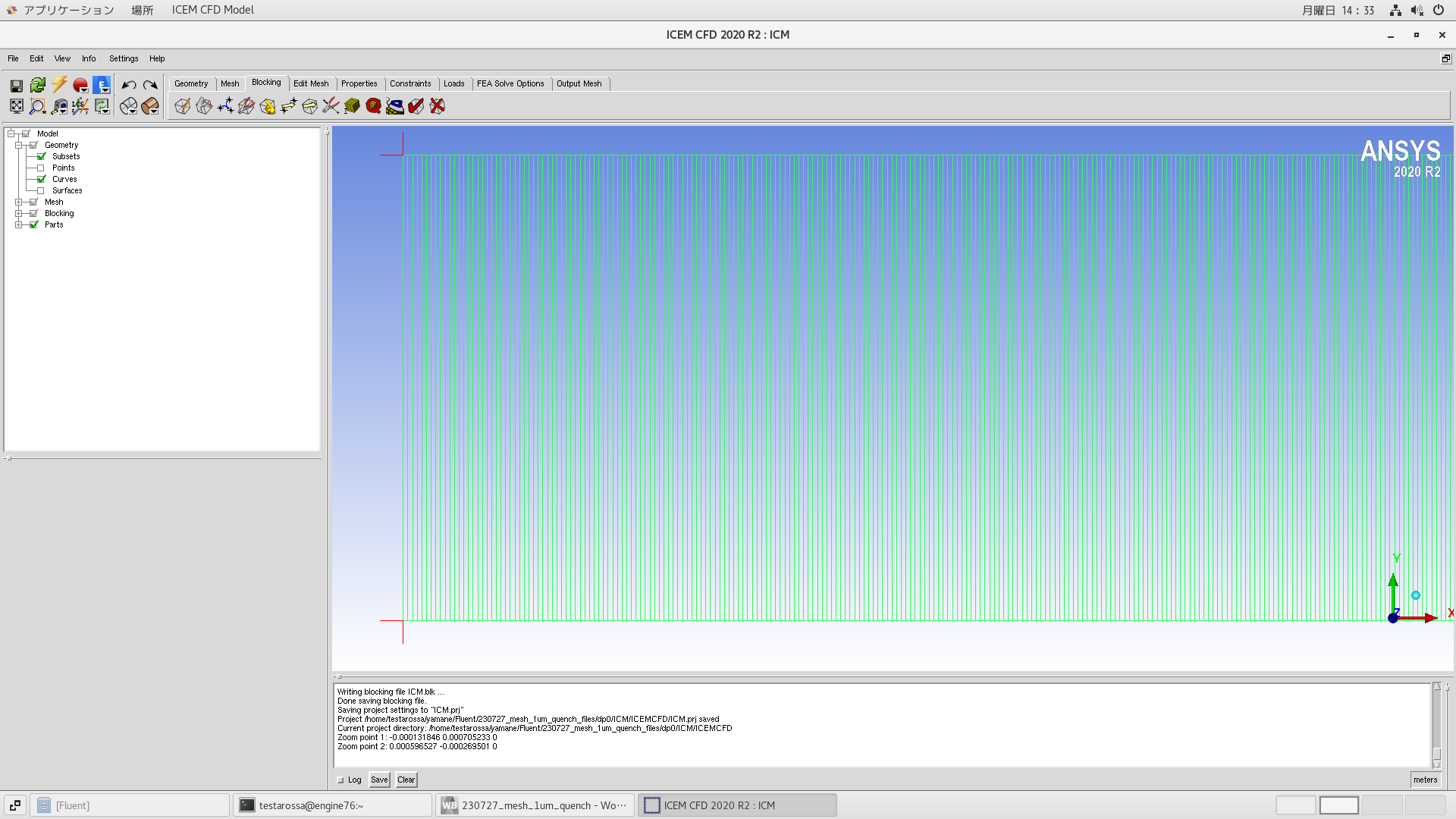

I want to calculate the flame propagation from right to left in a simple geometry as shown in the figure.

However, when I cut a one-dimensional-like mesh in a two-dimensional region as shown in the figure, the calculation does not converge.

I think it is probably a problem of the aspect ratio of the mesh, but I would like to know what I should pay attention to in cutting such a mesh and what I should pay attention to in the calculation conditions.

I do not want to cut a fine mesh in the vertical direction if possible, since the information I need is only one-dimensional information in the left and right directions of the figure.

The calculation area is 1 mm in height and 15 mm in width.

Sorry for the rudimentary question.

-

July 31, 2023 at 9:30 am

Essence

Ansys EmployeeHello,

Flame propagation in Fluent cannot be modeled in one dimension.

-

August 31, 2023 at 1:11 am

skimura

Subscriberthank you for reply.

I'm sorry late reply.

I understand one-dimentional calcuration is cannot in fluent.

So if I want to do this calculation, I need to use a 2D region and cut a fine vertical mesh? -

August 31, 2023 at 2:41 pm

Rob

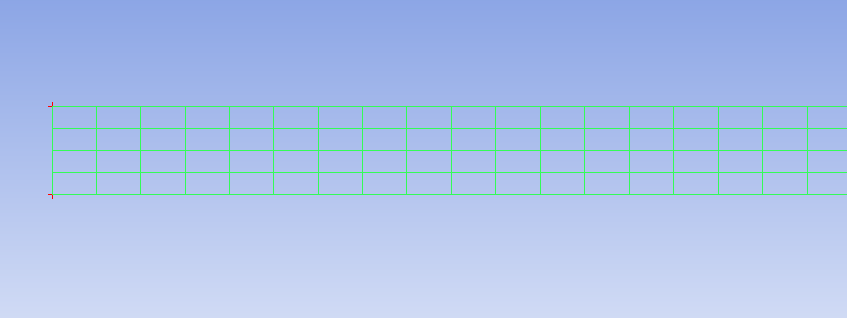

Forum ModeratorIn theory you could make a mesh with a lower y size and have an aspect ratio of 1. Set upper & lower edges as symmetry and you have the domain you want. The problem will be getting the fuel & oxident to mix with a layer of combustion products potentially separating the two. So, in practice it may not work well.

-

September 5, 2023 at 5:04 am

-

September 11, 2023 at 11:32 am

Rob

Forum ModeratorWhat happens when you try and run the model?

-

October 11, 2023 at 1:04 am

skimura

SubscriberHello Rob

This model was not stable and happen problem.

The initial flame was on the right side, but there was no flame propagation and the flame spread rapidly to the left side as if it was an abnormal combustion.

I think its you mentioned separating problem.

So, I am trying other geometry that original y sizing, near wall and y direction centor only fine mesh.

-

October 11, 2023 at 8:48 am

Rob

Forum ModeratorOK, with a 15mm domain size, how long would the flame take to cross the model? Flame speeds vary, but tend to be order of magnitude of m/s Note, I am not a combustion modelling expert (I have a colleague who is), but I am reasonably experienced in combustion chemistry. If you lit a stochiometric mixture of air & methane/kerosine vapour/whatever in a 15mm long tube would you expect the experimental instruments to measure anything useful? Or would it be over very quickly?

-

October 12, 2023 at 1:36 am

skimura

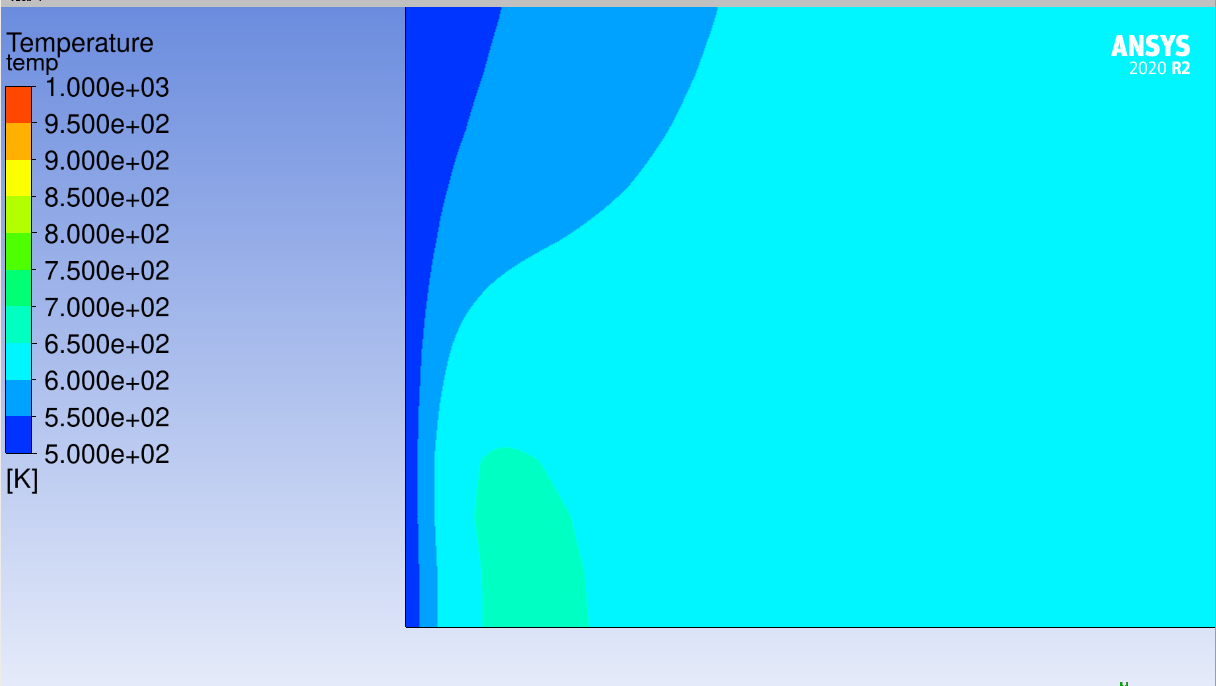

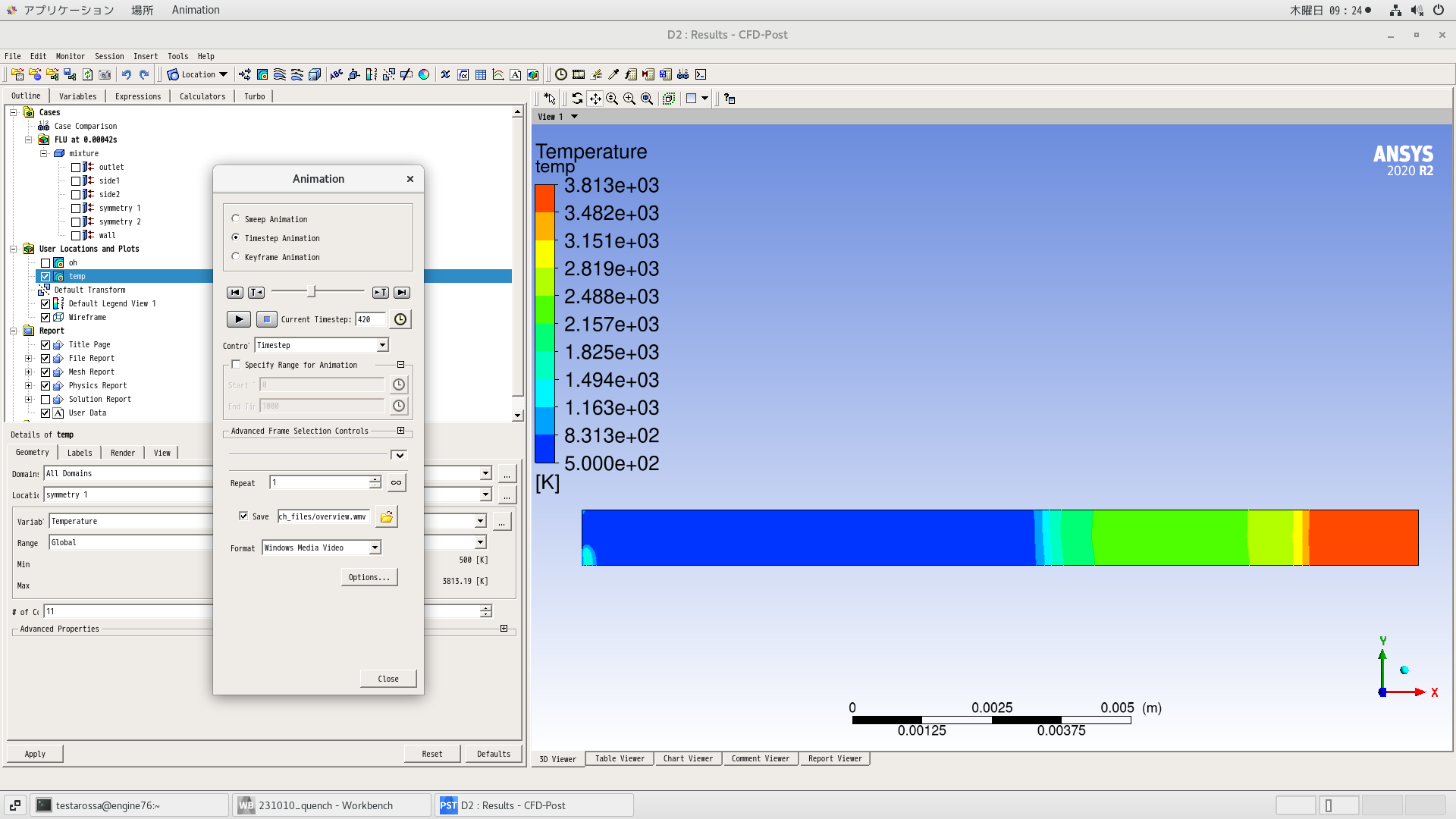

SubscriberI have other problem that start combustion at the boundary near the wall.

I attach two images, first all view at start abnormaly combustion, second same timing start combustion area.

Note, their images not same temperature scale.

Maybe Boundary conditions cause this problem.

Now I use "symmetry" condition. I am trying "periodic" conditon.

-

October 12, 2023 at 12:51 pm

Rob

Forum ModeratorMight be convergence, you'd need to check the results in the earlier steps. Don't use periodic in this case - symmetry is fine.

-

October 13, 2023 at 5:31 am

skimura

SubscriberOkay continue to use symmetry.

Confirmation of the previous step revealed OH of intermediate products near the wall at around 330 microseconds.

After that, the flame appears to spread from the area where OH was observed.

As for temperature, the lower side extends toward the wall from around 370 microseconds.

Are there any other results I should check?

Also, do you have any ideas to solve this problem?

Maybe it was a bad idea to coarsen the non-center mesh near the wall in order to focus on the center of the wall.

-

October 13, 2023 at 2:10 pm

Ren

Ansys EmployeeHello, Shin,

Let's clarify the problem first:

- What is the real geometry like? Is it a tube of 1mm diameter or a larger domain?

- what is the thermal boundary condition at the top and the bottom boundary, adiabatic?, cooled?

- What is the mixture made of and in what proportion (equivalence ratio)?

- What are you trying to predict, flame speed? flame temperature? product composition? time of travel? etc.

- What combustion model did you use? How did you establish the flame at the start of the domain?

-

October 16, 2023 at 5:00 am

skimura

SubscriberHello, Ren

Thank you for your kindful question.

- I use 2D plane its y size is 1 mm, x size is 15 mm

- Top and bottom boundary is use symmetry so it is adiabatic. Left boundary is wall that No slip, temperature=500K(fix), no adiabatic. Right boundary is Pressure outlet its set to 3.9MPa(gause),turn off reverse flow.

- Mixture is H2/Air its include h2, o2, n2. It's equivalence ratio is stoichimetric.

- I trying to predict that quenching distance and Heat loss at wall. I think quenching distance is define by temperature or product composition.

- I'm not use combustion model. I use Species model that input chemkin format mechanism and dilectly calcurate.

Input mechanism is "Hydrogen" . That refenrence below[M. Ó Conaire, H. J. Curran, J. M. Simmie, W. J. Pitz, C. K. Westbrook A Comprehensive Modelling Study of Hydrogen Oxidation, Intl. J. Chem. Kinet., 36 (11):603–622 (2004).]

Initial flame is using spark ignition model. It place near left boundary, X-centor 14.5mm, Y-centor 0mm, initial radius is 0.5 mm. Spark duration is 0ms-1ms(same to calcuration time),energy 10mJ, Flame spped model is "Laminar".

-

October 18, 2023 at 10:17 am

Ren

Ansys EmployeeFirstly, you need to have a proper 2D mesh as pointed out previously. The mesh needs to be fine enough in the x-direction compared with the flame thickness.

You also need to use the "Stiff Chemistry Solver" that can be activated in the "Species Model" dialog box.

Regarding the flame ignition, it's okay to use the ignition model but you can also try simply "patch" a temperature value and the mixture composition corresponding to the combustion products.

-

October 19, 2023 at 1:00 am

skimura

SubscriberUnderstood that the 2D mesh needs to be improved and the solver needs to be changed.

I would like to confirm two points about the "patch".

Is the "patch" in the "Initialization" configuration?

Since we are burning hydrogen in the stoichiometric system, does that mean that we should patch the area we want to be the existing burn area with hot water vapor and nitrogen?

-

October 19, 2023 at 10:38 am

Ren

Ansys EmployeeYes, Solution->Initialization->Patch... in the ribbon of Fluent interface.

Yes, h2o, n2 and a high T

-

October 31, 2023 at 1:25 am

skimura

SubscriberUnder one condition, the calculation is now correct.

I will try to calculate other conditions as well.

Thank you very much for your advice.

-

- The topic ‘One-dimensional-like computation in fluent’ is closed to new replies.

-

3427

-

1057

-

1051

-

896

-

892

© 2025 Copyright ANSYS, Inc. All rights reserved.