-

-

August 9, 2023 at 3:59 pm

fraser.shields

SubscriberHi,

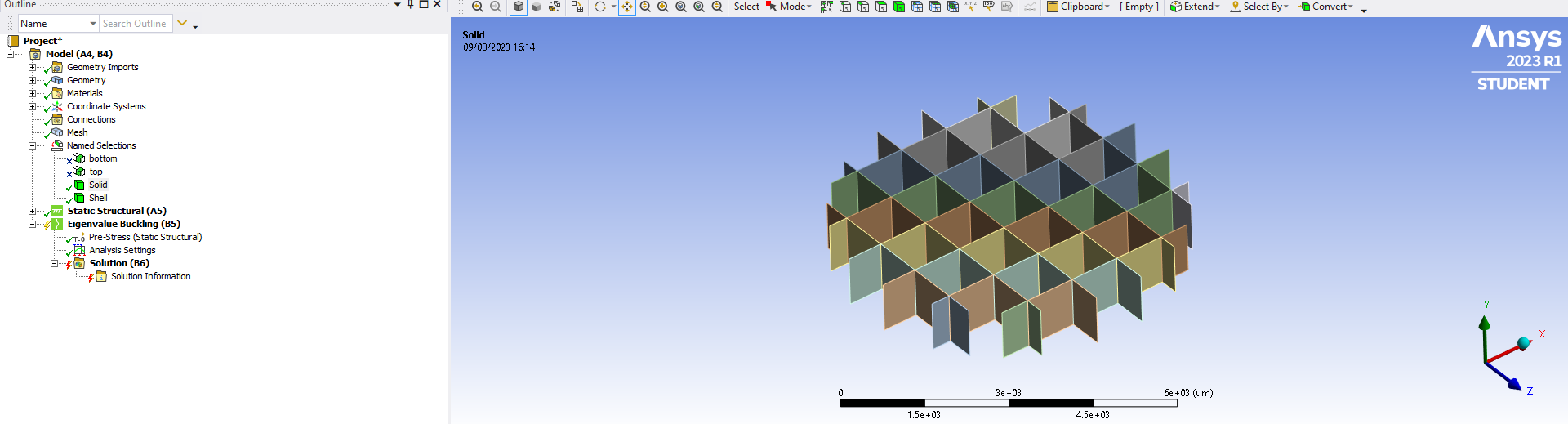

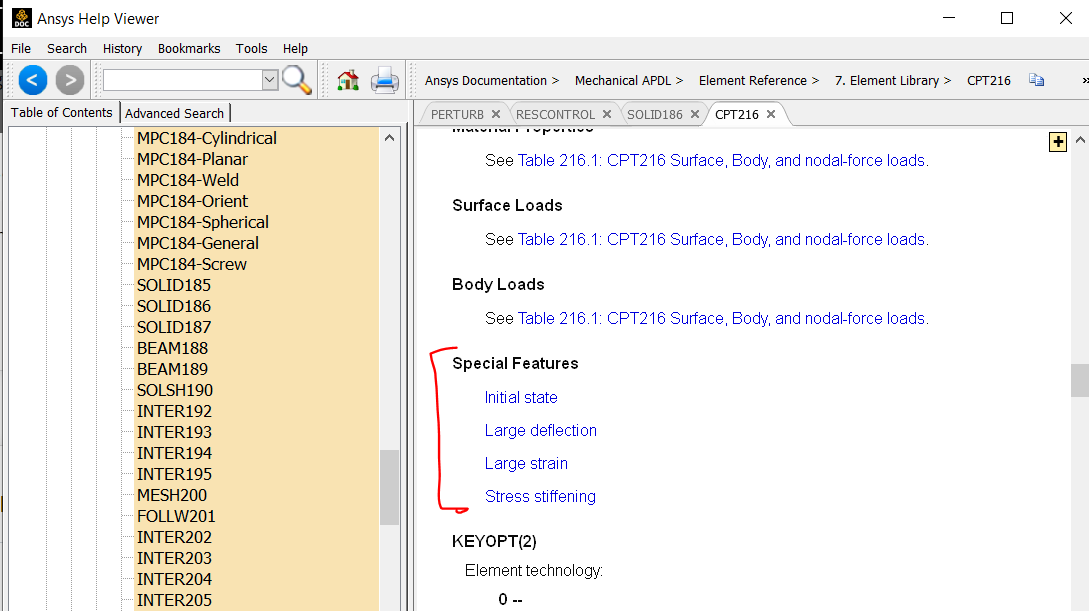

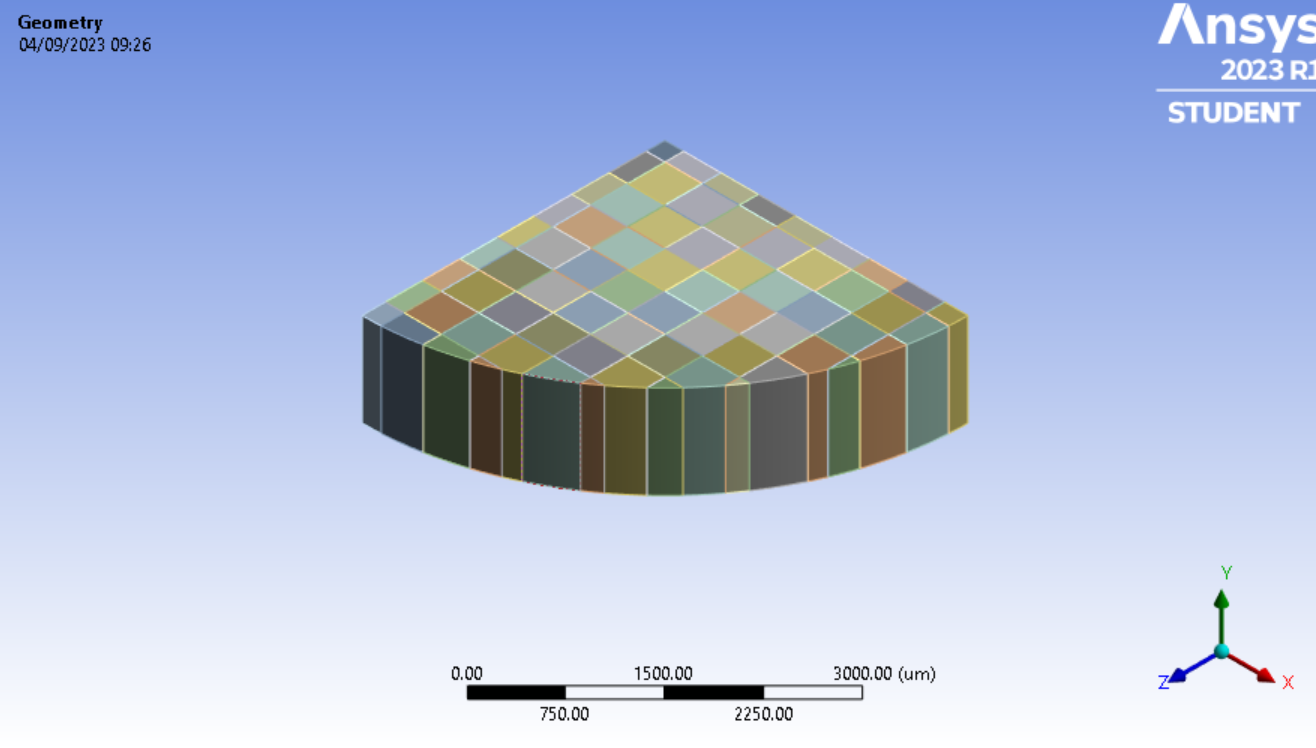

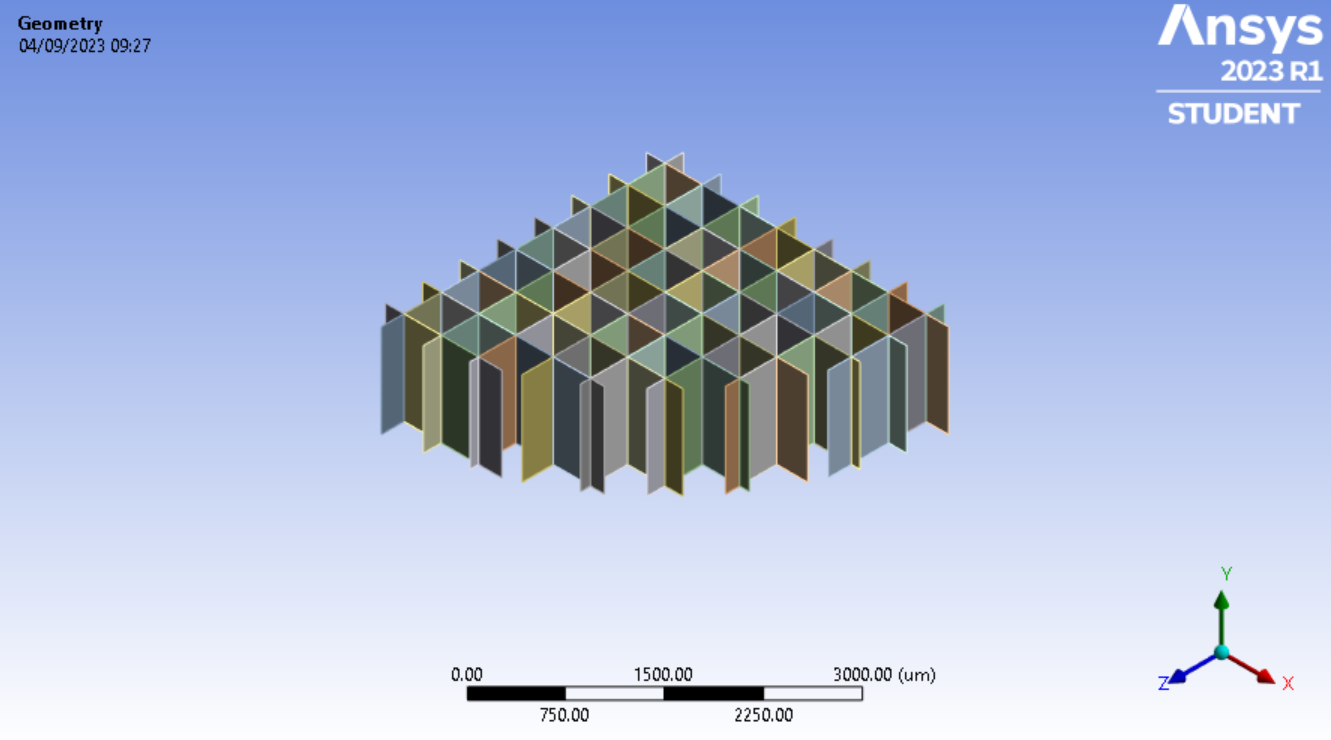

I am modelling an elastic (E = 1 kPA, v=0.3) poro-fluid solid (CPT216 elements) reinforced with a stiff (E= 300 MPa, v=0.3) linear elastic shell (Shell281 elements). The model has a compressive ramp displacement parallel to the shell face (perpendicular to disc CSA in attached images) followed by a stress relexation period up to t=1000s. The mesh is conformal between the solid and shell elements, thus no contact is required. The linear simulation is giving very large reaction forces on the bottom face of the disc, I believe this is because the shell is not buckling.

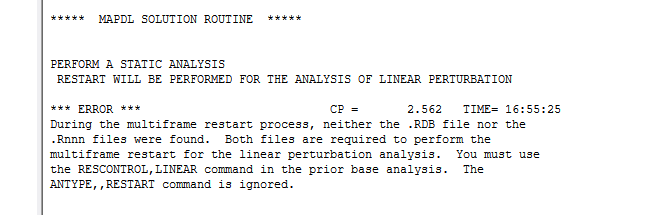

When attempting a non-linear analysis (large deformations ON), the solver fails on the first step due to inverted elements - I imagine due to buckling. Therefore, I am attempting to model non-linear buckling by first modelling linear buckling and then using the first buckling mode for the non-linear analysis. However, upon solving linear eigenvlue buckling I get the following error:

Any ideas why? I am using Student Versions 2023 R1.

-

August 11, 2023 at 11:23 am

Ashish Khemka

Forum ModeratorHi Fraser,

Did you try resolving the first analysis with the command indicated in the error message?

Regards,

Ashish Khemka

-

August 11, 2023 at 11:37 am

fraser.shields

SubscriberHi Ashish,

Thanks for getting back to me.

Yes I attempted to use the suggested command in my /prep7 command snippet:

! Commands inserted into this file will be executed just prior to the ANSYS SOLVE command.

! These commands may supersede command settings set by Workbench.! Active UNIT system in Workbench when this object was created: Metric (um, kg, uN, s, V, mA)

! NOTE: Any data that requires units (such as mass) is assumed to be in the consistent solver unit system.

! See Solving Units in the help system for more information./PREP7

! Define an element type with the desired real constant (CPT216)

ET, 9991, CPT216

! Set element key option to Structural-pore-fluid-diffusion loading

KEYOPT, 9991, 12, 1

! Select the solid elements you want to modify (SOLID186)

ESEL, S, TYPE,, 13, 57

! Modify the selected elements to use the specified element type (9991)

EMODIF, ALL, TYPE, 9991ESEL, NONE

! Define proelastic material for solid elements

MP,EX,99999,0.001 ! YOUNG'S MODULUS

MP,NUXY,99999,0.3 ! POISSON'S RATIO

FPX=1e6 ! PERMEABILITY

ALPHA=1 ! BIOT coeffient

TB, PM, 99999,,,PERM

TBDATA,1,FPX,FPX,FPX

TB,PM,99999,,,BIOT ! BIOT COEFFICIENT

TBDATA,1,ALPHA, KM

ESEL, NONE! Define linear elastic material for shell elements

MP,EX,88888,300 ! YOUNG'S MODULUS

MP,NUXY,88888,0.3 ! POISSON'S RATIOALLSEL, ALL

! Select the solid elements you want to modify and assign material 1

ESEL, S, TYPE,, 9991

MPCHG, 99999, ALLALLSEL, ALL

! Select the shell elements you want to modify and assign material 2

ESEL, S, TYPE,, 1, 12

MPCHG, 88888, ALLALLSEL, ALL

! impervious (fluid flow flux=0)

NSEL,S,LOC,Y,1000 ! select top surface nodes

NSEL,A,LOC,Y,0 ! select bottom surface nodes

SF,ALL,FFLX,0 ! Set surface force (fluid flow flux) to zeroALLSEL, ALL

! permeable (fluid pressure=0) on sides of cylinder to allow fluid flow

CSYS, 5 ! change coordinate system to cylindrical with cartesian y as axis of rotation

NSEL,S,LOC,X,3250 ! select nodes at radius=3250um

D,ALL,PRES,0 ! set fluid pressure to zeroALLSEL, ALL

CSYS, 0 ! change coordinate system back to global coordinates

! Select all elements

ALLSEL, ALLRESCONTROL, LINEAR

/SOLUHowever, I still get the same error.

Within the static structural solver output, I get the following message:

For some reason, the solver isn't creating any multiframe restart files due to my elements being couples pore diffusion CP216?

-

August 11, 2023 at 4:25 pm

Bill Bulat

Ansys Employee-

August 18, 2023 at 4:12 pm

fraser.shields

SubscriberHi Bill, any ideas how I can get this to run without using linear perturbation to get the buckling mode?

-

-

August 11, 2023 at 4:53 pm

fraser.shields

SubscriberHi Bill,

Thanks for the information. What would you suggest? How can I perform a non-linear analysis which includes buckling of the shell elements without using linear buckling to get the first buckling mode?

Best,

Fraser

-

August 16, 2023 at 12:56 pm

fraser.shields

SubscriberStill unable to run this model in a non-linear analysis. Any suggestions would be much appreciated? How do I model the buckling of the structure when the load is acting in plane for the shell elements? I can't use linear perturbation due to having CPT216 elements in my model - how else can I induce buckling?

-

August 18, 2023 at 8:15 pm

peteroznewman

SubscriberTry a multistep solution sequence.

Step 1. Apply pressure to the non-facesheet panel walls to create some small deformation to seed the buckling.

Step 2. Apply some of the axial load to the facesheet to "hold" the small deformation from step 1 from leaving.

Step 3. Ramp on some more axial load while ramping off the pressure load to zero.

Step 4. Apply the remainder of the axial load.

I suggest alternating the direction of pressure in adjacent cells.

-

September 4, 2023 at 8:25 am

fraser.shields

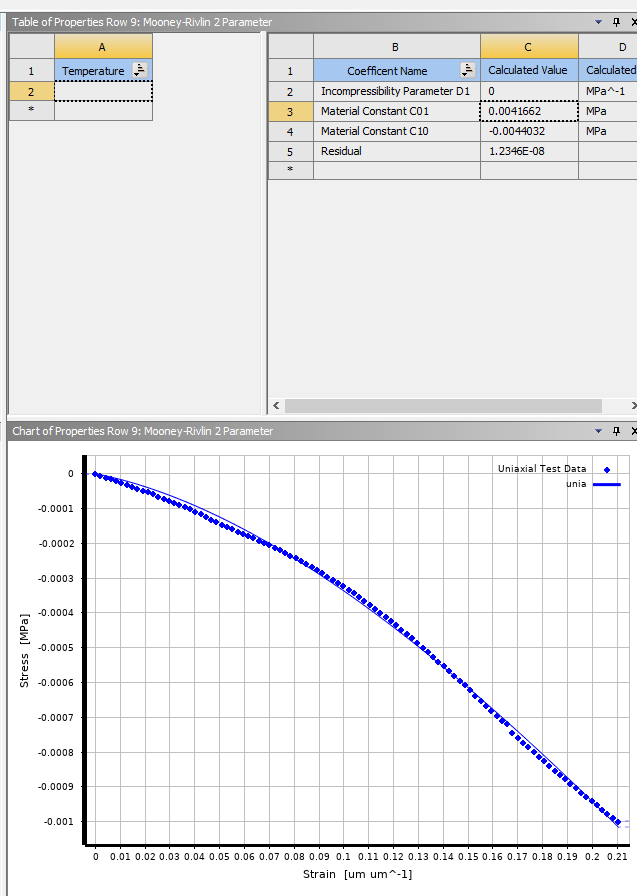

SubscriberHi Peter, thanks for the response. I’ve simplified the model down to it’s symmetry planes and it seems to run when the solid and shell moduli are similar in magnitude – even without applying any pressure to the shell walls. However, in reallity the solid modulus is actually significantly smaller than the shell modulus – approx. 1 kPa compared to 300MPa (shell elements have orthotropic properties, 300MPa parallel to facesheet, 1 kPa normal to facesheet). I have attempted to fit a Mooney-Rivlin hyperelastic model to some experimental data. However, this has not helped with convergence.

The command snippet is the following:

! Commands inserted into this file will be executed just prior to the ANSYS SOLVE command.! These commands may supersede command settings set by Workbench.! Active UNIT system in Workbench when this object was created: Metric (um, kg, uN, s, V, mA)! NOTE: Any data that requires units (such as mass) is assumed to be in the consistent solver unit system.! See Solving Units in the help system for more information./PREP7! Define an element type with the desired real constant (CPT216)ET, 9991, CPT216KEYOPT, 9991, 12, 1!KEYOPT,9991,6,1! Select the solid elements you want to modify (SOLID186)ESEL, S, TYPE,, 1, 69! Modify the selected elements to use the specified element type (9991)EMODIF, ALL, TYPE, 9991ESEL, NONETB,HYPER,99999,,,MOONEYTBDATA,1,-0.0042, 0.0044, 0 !c1 , c2 = material constants characterizing the deviatoric deformation of the material, c2=incompressibility parameterFPX=1e5 ! PERMEABILITYALPHA=1 ! BIOT coeffientTB,PM,99999,,,PERMTBDATA,1,FPX,FPX,FPXTB,PM,99999,,,BIOT ! BIOT COEFFICIENTTBDATA,1,ALPHAESEL, NONE! Define orthotropic elastic material for shell elementsMP,EX,88888,300 ! YOUNG’S MODULUSMP,EY,88888,0.001MP,EZ,88888,0.001MP,GXY,88888,150MP,GXZ,88888,0.001MP,GYZ,88888,0.001MP,NUXY,88888,0 ! POISSON’S RATIOMP,NUXZ,88888,0MP,NUYZ,88888,0ALLSEL, ALL! Select the solid elements you want to modify and assign material 1ESEL, S, TYPE,, 9991MPCHG, 99999, ALLALLSEL, ALL! Select the shell elements you want to modify and assign material 2ESEL, S, TYPE,, 70, 189MPCHG, 88888, ALLALLSEL, ALL! impervious (fluid flow flux=0)NSEL,S,LOC,Y,1000 ! select top surface nodesNSEL,A,LOC,Y,0 ! select bottom surface nodesSF,ALL,FFLX,0 ! Set surface force (fluid flow flux) to zeroALLSEL, ALLESEL, NONE! permeable (fluid pressure=0) on sides of cylinder to allow fluid flowCSYS, 5 ! change coordinate system to cylindrical with cartesian y as axis of rotationNSEL,S,LOC,X,3250 ! select nodes at radius=3250umD,ALL,PRES,0 ! set fluid pressure to zeroALLSEL, ALL!CMSEL,S,internal_free_draining,node!D,ALL,PRES,0CSYS, 0 ! change coordinate system back to global coordinatesALLSEL, ALL! Continue with the solution phase/SOLUAny ideas how I could get this model to run with such large differences in stiffness between the solid matrix and reinforcing shell elements?Thanks in advance.Here is a linke to the archive file - can't figure out how to attach it to the comment:

https://livemanchesterac-my.sharepoint.com/:u:/g/personal/fraser_shields_postgrad_manchester_ac_uk/Eeew5xpFBGJPhyT0oSj4tRYB3mcMUJdEk-aWrWNkDLMmoA?e=Xc1juw

-

September 12, 2023 at 12:28 pm

fraser.shields

SubscriberHi Peter,

I am still struggling to get this model to converge? Do you have any insights as to why it isn't converging?

Thanks,

Fraser

-

-

- The topic ‘Non-linear convergence problems’ is closed to new replies.

-

3467

-

1057

-

1051

-

929

-

896

© 2025 Copyright ANSYS, Inc. All rights reserved.