-

-

November 17, 2022 at 1:51 pm

javat33489

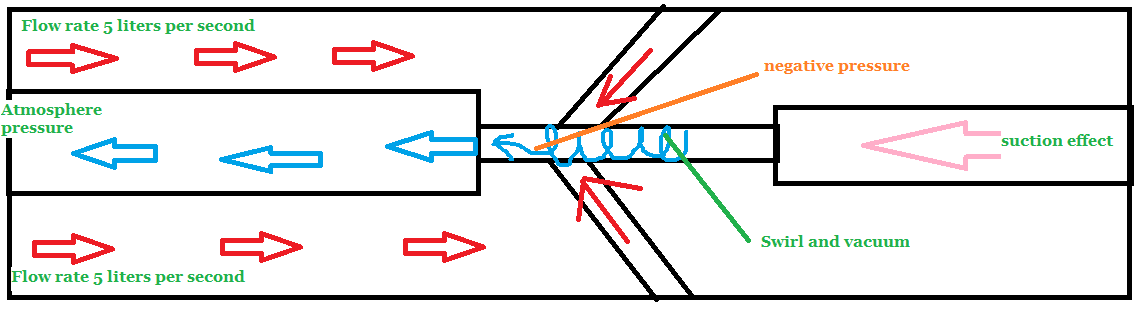

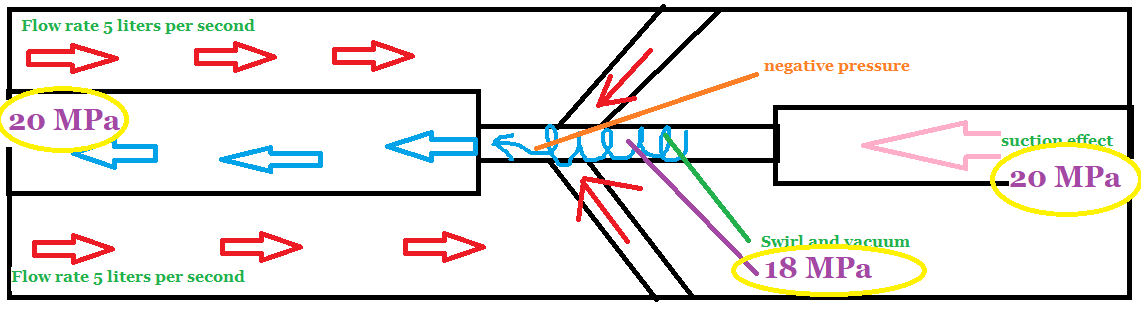

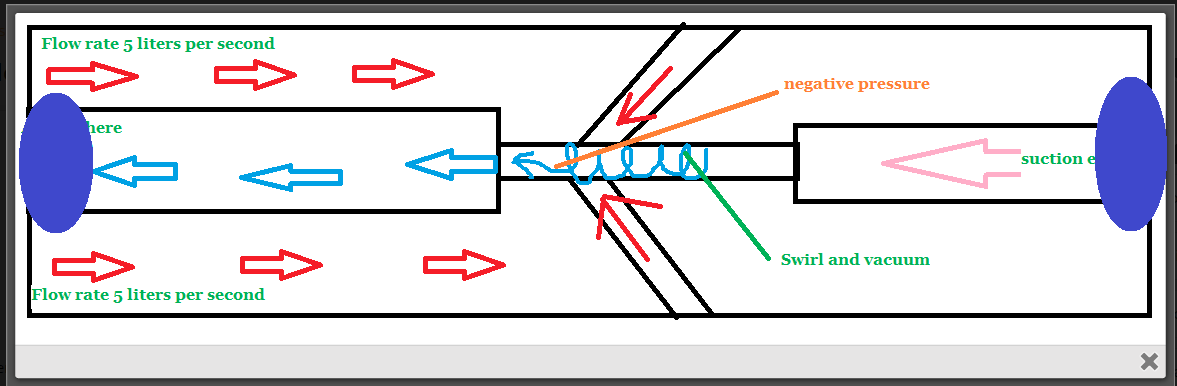

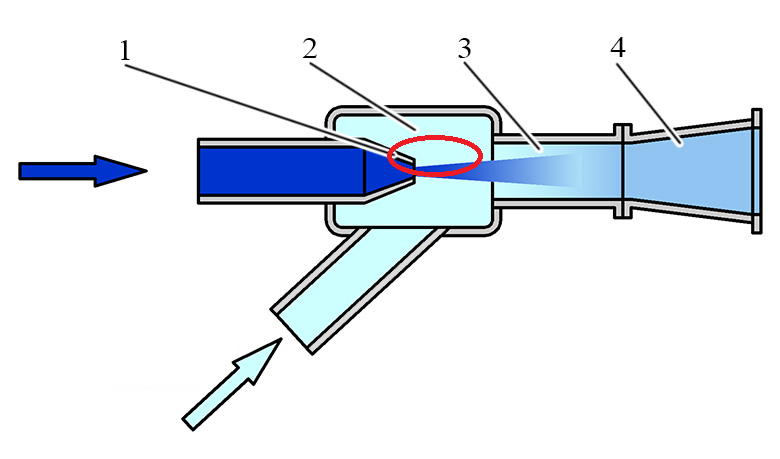

SubscriberHi all. I have a problem. Help me please. Good knowledge in CFD is required. I'm counting a jet downhole choke. This fitting creates a vacuum when liquid is supplied to it, due to the vacuum, it sucks out the liquid after the fitting. I set the flow rate to 5 liters per second, which is fed into this fitting (red), goes through the radial channels and enters the chamber where it creates a vacuum due to the round flow. There is atmospheric pressure at the outlet of this nozzle (blue) and where the nozzle also sucks out atmospheric pressure (pink). When calculating in the vacuum chamber, it shows negative pressure. Why? What else can be asked? What could be the problem?

-

November 17, 2022 at 2:32 pm

Rob

Forum ModeratorI think you have a swirling flow in the centre section? That's creating a vortex core, and that can create the suction effect. Some CFD images will help explain what's going on: tangential velocity and pressure would be good.

-

November 17, 2022 at 4:41 pm

javat33489

SubscriberYes, that's right, there are vortices that create a suction effect and in this place the pressure is -1.5 MPa, this does not happen

-

-

November 17, 2022 at 4:56 pm

Rob

Forum ModeratorHow does the convergence look? What is the operating pressure, remember you're (probably) reporting gauge. Please post some images.

-

November 17, 2022 at 5:03 pm

javat33489

SubscriberSorry I can't attach images. The flow rate at the inlet is 5 liters per second, which creates a pressure of 6 MPa. The task of the device is to cause an influx of fluid due to the vacuum in the tangential chamber. Due to this, the liquid should be sucked out of the pink area (see picture). But in the rarefaction zone there is a negative pressure, this does not happen in nature. The mesh is very good, at least 5 elements across the narrowest channels. Ke turbulence model. Convergence is achieved in 300 iterations.

I tried to make a calculation under the condition of cavitation, then there is no convergence at all, the outlet pressure constantly jumps.

-

-

November 17, 2022 at 5:42 pm

Rob

Forum ModeratorWith high swirl you'll need RSM: read the theory on the 2-equation turbulence models. How much mesh have you got in the swirl region?

The insert images button is in the menu below where you're typing the words.

-

November 17, 2022 at 5:58 pm

javat33489

Subscriber>>With high swirl you'll need RSM: read the theory on the 2-equation turbulence models. How much mesh have you got in the swirl region?

I used K-epsilon. What model would you recommend?

>>The insert images button is in the menu below where you're typing the words.

Images on a working PC. I am not allowed to send them((

-

-

November 18, 2022 at 10:15 am

Rob

Forum ModeratorRSM: read the documentation to understand the limitations of 2-equation models in high swirl. Read the various threads on cyclones: they'll give you further advice on what's needed.

OK, are you working with Student, Research or Commercial licences? The former are for learning, so confidential work is against the terms, the latter means you should have access to direct support.

-

November 18, 2022 at 5:56 pm

javat33489

SubscriberI am writing it here. So that if someone has such a problem, they can solve it. Let's solve it together.

Noticed this feature. If I set the outlet pressure and the place where the vacuum will suck out the liquid. Then there is no negative pressure in the center, the pressure is simply less.

What do you think about this?

-

-

November 22, 2022 at 11:45 am

Rob

Forum ModeratorIf you're setting pressure differently, then you're solving a different model. How are you setting pressure in the swirling region?

-

November 22, 2022 at 1:09 pm

javat33489

Subscriber-

November 25, 2022 at 1:31 pm

javat33489

SubscriberMaybe a non-stationary analysis is needed for the turbulent zone? How to choose the right calculation time and substeps? I think the calculation time is 1 second and the substep is 1e-6

-

-

-

November 25, 2022 at 3:26 pm

Rob

Forum ModeratorI think you need to carefully work through how the device works, and then review the model settings.

-

November 27, 2022 at 10:07 am

-

-

November 29, 2022 at 9:48 am

Rob

Forum ModeratorOK, so you have a known mass flow for the primary nozzle, a (probably atmospheric) secondary feed and an outlet at a different pressure. That may then discharge into a larger vessel. You will (should) know most of the data you need.

I've modelled a few of these, and helped my PhD supervisor clean up after a few experimental mishaps. They're far more complex than people realise, and the throat dimensions and ratios are critical to good operation: same as in vortex amplifiers.

-

November 29, 2022 at 1:15 pm

javat33489

SubscriberHow will this post help me? Can you help me? How to get rid of the negative pressure in the center? The inlet flow rate is 5 liters/second. Discharged to the atmosphere (into the container but from above, so the pressure is atmospheric, because the container is not filled). At the second inlet, the pressure is also atmospheric. The experiment is such that water is supplied at a flow rate of 5 l / s, pressure gauges are installed and they measure how air is sucked in from the vacuum inside the chamber and water is thrown into the tank.

-

-

November 29, 2022 at 4:19 pm

Rob

Forum ModeratorGiven you've not shown any results it's hard to say if you have the correct answer. If you're venting to an open vessel you may need to include that: is setting 0Pa in the outlet nozzle physically correct?

-

November 29, 2022 at 4:23 pm

javat33489

SubscriberI wrote, in the exhaust pipe is atmospheric pressure

-

-

November 29, 2022 at 4:51 pm

Rob

Forum ModeratorThe nozzle is venting to atmosphere, given the flow is the nozzle at atmospheric pressure?

-

November 29, 2022 at 5:01 pm

javat33489

SubscriberAt the inlet to the pump, I set the flow rate, and at the outlet, atmospheric pressure, the program itself calculates the flow rate in the chamber (in the nozzle). Need to set nozzle pressure?

-

-

November 29, 2022 at 5:34 pm

Rob

Forum ModeratorAs it's the outlet how confident are you that it's zero Pa, as opposed to zero in the chamber it exhausts to?

-

November 29, 2022 at 5:41 pm

javat33489

SubscriberNo, it's not like that. Water enters through the nozzle into the pump chamber - then the water from the pump chamber goes outside into the tank under atmospheric pressure. I did not put pressure on the nozzle, only on the inlet to the pump and the outlet from the pump chamber, and after the nozzle into the pump chamber, the program calculates itself.

-

-

November 29, 2022 at 7:33 pm

-

November 30, 2022 at 9:55 am

Rob

Forum ModeratorThe tank is at atmospheric pressure, but the nozzle into the tank has a discharge coefficient, and will (probably) have some interesting flow effects. The negative pressure around the water jet is how jet pumps/ejectors work. Go through a few tutorials and read the documentation, neither of your problems are too complicated with a bit of experience.

-

November 30, 2022 at 1:11 pm

javat33489

SubscriberBut in nature there is no negative pressure. How to eliminate it?

-

-

November 30, 2022 at 1:26 pm

Rob

Forum ModeratorAs I still haven't seen any pictures, including convergence plots I can't really comment.

-

December 6, 2022 at 4:25 pm

javat33489

SubscriberOk I will take some pictures

-

December 8, 2022 at 2:41 pm

-

-

December 8, 2022 at 2:53 pm

Rob

Forum ModeratorThat's a weird looking ejector. What speeds and density fields are you seeing?

-

December 27, 2022 at 8:16 pm

javat33489

SubscriberI calculate the ejector again. I have a mass flow rate of 5 l / s at the inlet to the ejector, but according to the calculation, the output is 24 l / s, and that the ejector sucks only 2 l / s, there should be a total output of 7 l / s. What is the problem? At the outlet of the ejector, atmospheric pressure is set; at the inlet to the ejector from the side of the tank, atmospheric pressure is also set. Problem with ejector calculation in FLUENT

-

-

January 3, 2023 at 3:00 pm

Rob

Forum ModeratorThe solver will (assuming the mesh is OK and it's converged) give the correct answer for the defined boundary conditions. However, as I can't see the solution I can't comment. I'm also not permitted to download case files so can only advise in general terms.

-

- The topic ‘Negative pressure problem’ is closed to new replies.

-

3572

-

1188

-

1076

-

1063

-

952

© 2025 Copyright ANSYS, Inc. All rights reserved.