-

-

November 2, 2024 at 8:11 am

fan134

SubscriberHello,

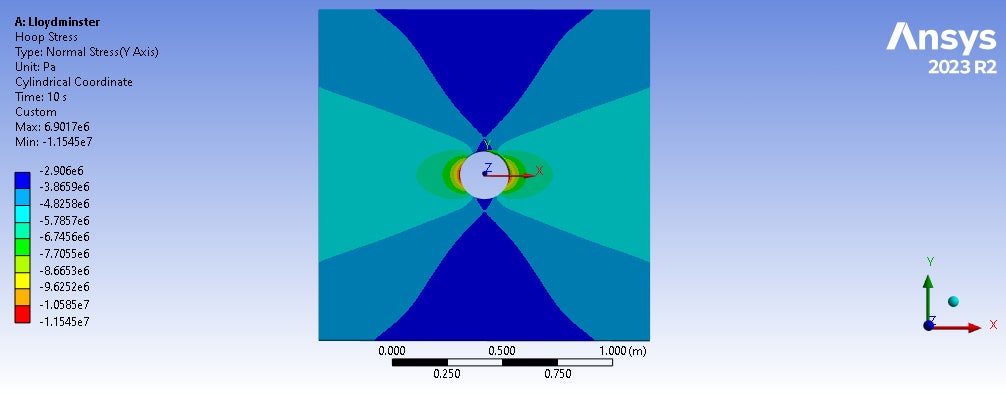

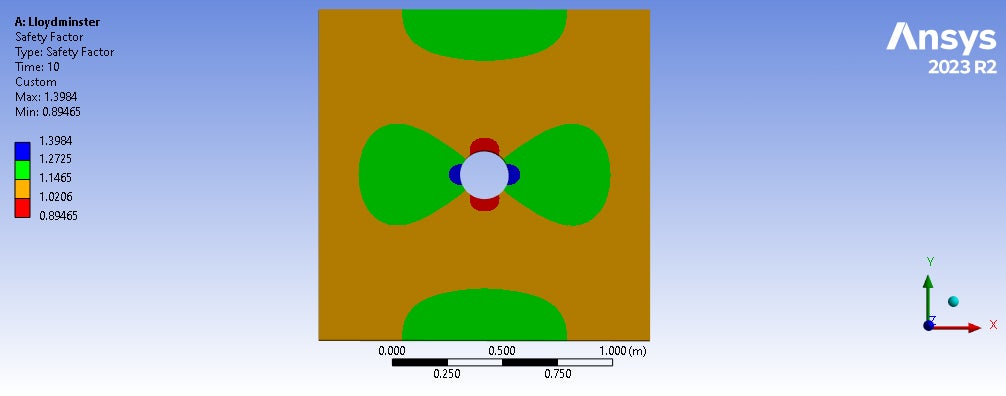

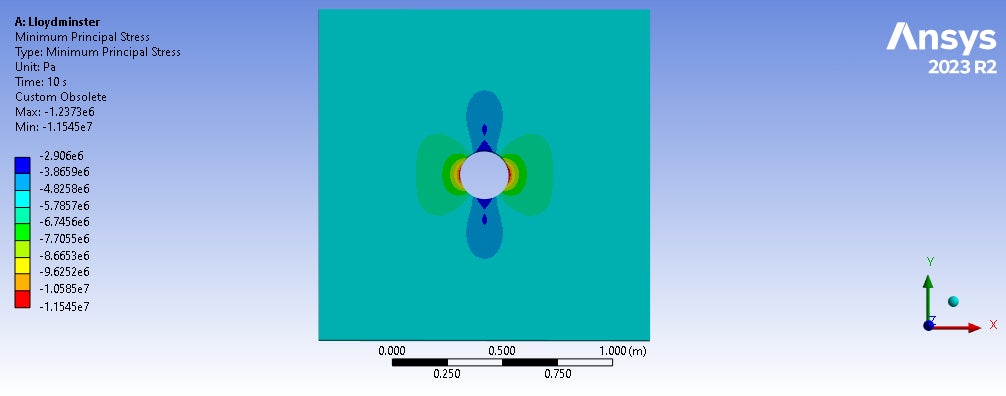

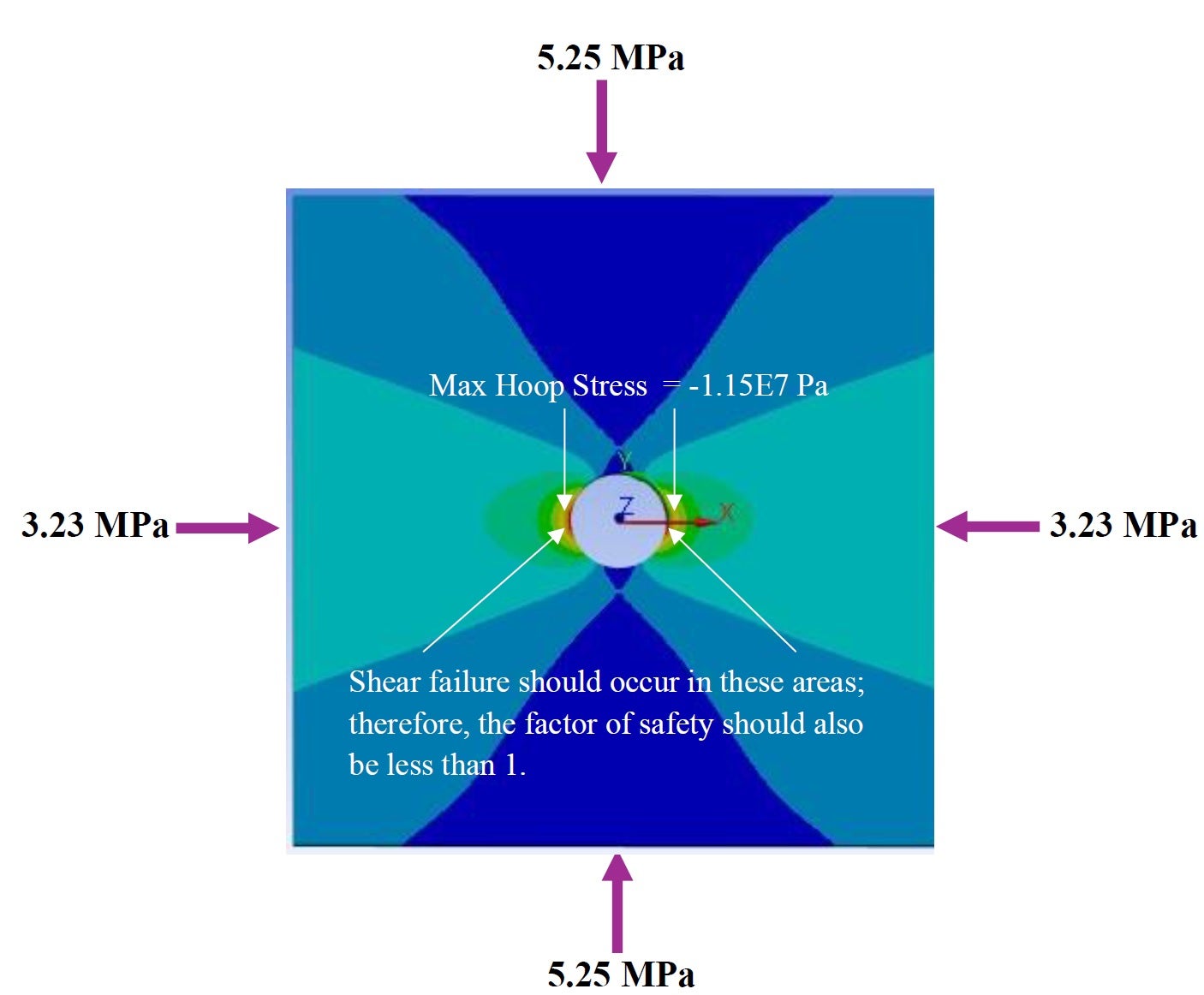

I am conducting a geomechanical analysis on sandstone. The hole in the center denotes a wellbore. The effective minimum horizontal stress is 3.23 MPa, acting in the X-direction, while the effective maximum horizontal stress is 5.25 MPa, acting in the Y-direction. The tensile and compressive ultimate strengths of sandstone are 2.08 MPa and 47.5 MPa, respectively. The maximum hoop stress occurs in the direction of the minimum horizontal stress (X-direction). Logically, shear failure should occur in that direction as well. However, when I calculated the safety factor using the Mohr-Coulomb stress tool, I observed that failure (Safety Factor<1) is occurring in the direction of the maximum horizontal stress (Y-Direction), which seems inconsistent.

I would greatly appreciate any assistance in resolving this issue. Thanks in advance.

Hoop Stress

Safety Factor

Maximum Principal Stress

Minimum Principal Stress

-

November 4, 2024 at 4:24 pm

Pedram Samadian

Ansys EmployeeHi,

Are those mentioned stress values from the same location or different locations around the hole? Please note that the Mohr-Coulomb Stress Safety tool evaluates maximum and minimum principal stresses at the same locations and does not base its calculations on the absolute maximum principal stress and the absolute minimum principal stress occurring at two different locations in the body. In other words, the combination of the maximum and minimum principal stresses in each spot determines the possibility of failure using this tool. You can find further information about this tool in the following link: Mohr-Coulomb Stress Safety Tool

I hope this guidance helps.

Thanks,

Pedram

-

November 5, 2024 at 5:55 am

fan134

SubscriberHello Pedram,

Thank you for your response. I’ve attached a picture to help address your question. I’m already familiar with how the Mohr-Coulomb safety tool calculates the safety factor. In geomechanics, it’s a well-known fact that shear failure typically occurs around the hole in the direction of the minimum horizontal stress, where the hoop stress is highest. In my case, minimum horizontal stress is 3.23 MPa, acting in the X-direction. Therefore, the factor of safety in these areas should be less than 1. However, the Mohr-Coulomb safety tool is showing a safety factor greater than 1 in these regions. Could you help clarify why this safety tool contradicts a geomechanical fact?

Regards,

Faysal

-

November 5, 2024 at 7:38 pm

Pedram Samadian

Ansys EmployeeHi,

Thanks for the clarification. Would you please check the Mohr-Coulomb criterion manually for the elements located in those regions based the predicted maximum and minimum principal stresses?

If you get a safety factor of lower than unity similar to LS-DYNA and are sure that it should be more than unity in those regions, I would suggest reducing the element size, specifically around the hole edge. Moreover, try using higher-order element types (quadratic), which often improve stress results near discontinuities.

I hope this helps.

Thanks,

Pedram

-

November 6, 2024 at 4:32 am

fan134

SubscriberHello Pedram,

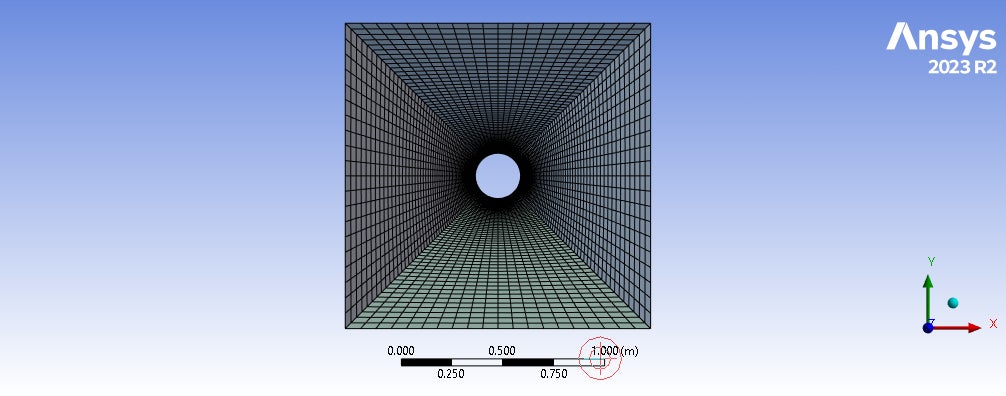

Thank you for your response. I manually calculated the Mohr-Coulomb criterion for the elements in those regions using the predicted local maximum and minimum principal stresses. The resulting safety factor matches exactly with the one shown in the image attached to the original post. The model was created using static structural not LS-DYNA, and I used higher-order elements (CPT-216) with a sufficiently refined mesh around the hole, as shown in the attached picture. The total number of elements in the model is 13,600. Radial and hoop stress distributions were validated against analytical models. The only issue I’m encountering is with the prediction of shear failure. For your information, I used the Mohr-Coulomb failure criterion for the material as well. Is there anything else you can think of that might affect the results?

Regards,

Faysal

-

November 6, 2024 at 9:52 pm

Pedram Samadian

Ansys EmployeeHi Faysal,

No problem. Thanks for the info. You mentioned that the radial and hoop stresses were validated against the analytical models. Do you mean the analytical models predicted similar values for these stresses to the finite-element ones? If so, the Mohr-Coulomb criterion may not be conservative enough to predict failure for the current combination of minimum and maximum principal stresses.

Regards,Pedram

-

- You must be logged in to reply to this topic.

-

3367

-

1050

-

1047

-

886

-

837

© 2025 Copyright ANSYS, Inc. All rights reserved.