-

-

December 21, 2023 at 1:21 pm

Ata Sabra

SubscriberHello,

I am trying to model a phase change material (RT21). I am doing it in Ansys Workbench as a thermal- transient analysis (not in Fluent!).

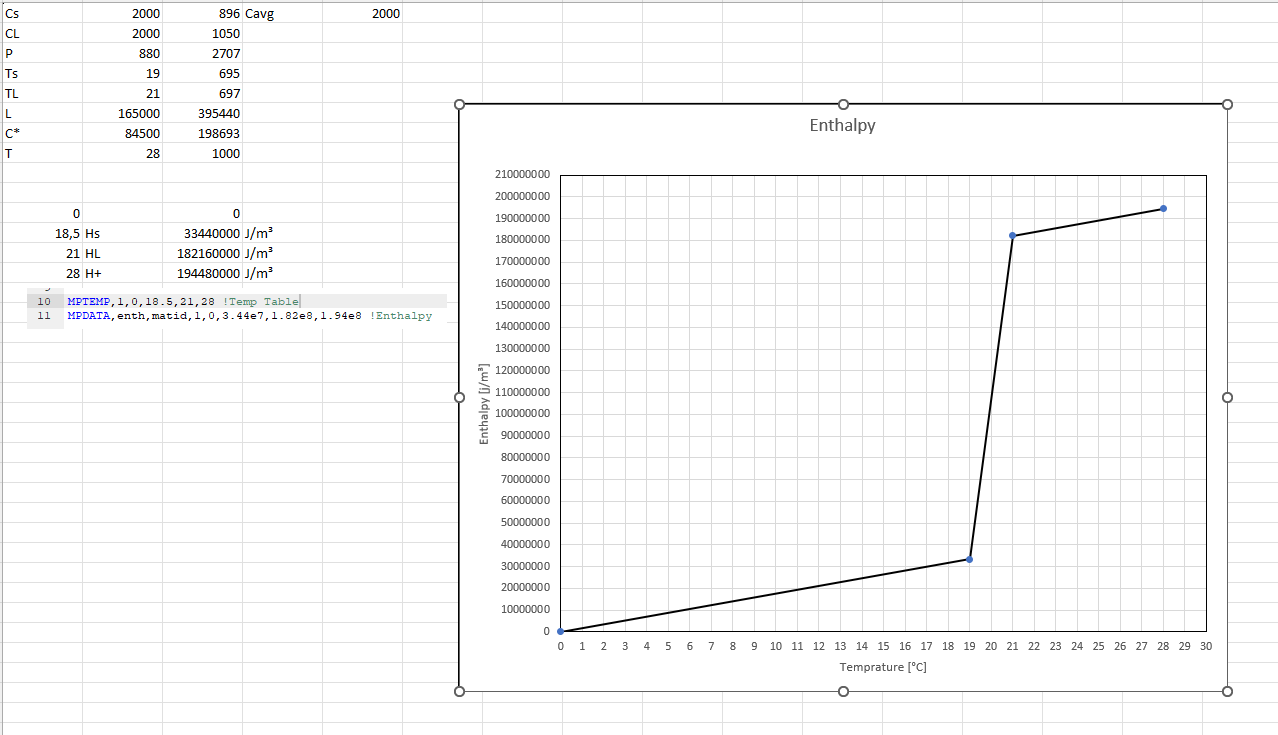

In order to do this I had to define the materials properties in engineering data and the enthalpy as a APDL- command. I did it and calculated the enthalpy of the material first (1.Photo). now when I define the enthalpy through mpdata like I caculated: 3.4e7, 1.82e8, 1.94e8 (J/m³) I get wrong tempratures for the material as a result (I have experimental Data to compare with).

When I put the enthalpy like this: 3.4e6, 1.82e7, 1.94e7 (J/m³) (division on 10), I get correct results as the labor- data.

The calculation of the enthalpy is correct. In which units do I have to put the enthalpy when I use the mpdata- command?

Can anyone please tell me if I am doing something wrong.

Thanks in advanced

-

December 22, 2023 at 12:18 pm

Chandra Sekaran

Ansys EmployeeI suspect something to do with unit system. When you use APDL commands to input data as you have done here, no unit conversion is done i.e. the enthalpy values are passed as such to the solver. However for other quantities Mechanical may be doing some conversions to get consistent solver units (explained in https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v232/en/wb_sim/ds_solving_units.html?q=solver%20units ) in the 'Understanding Solving Units' section. So it is best to enter the Enthalpy data in Engineering Data so unit conversions are taken care of by the program. Enthalpy is supported in engineering data.

-

December 22, 2023 at 1:44 pm

Ata Sabra

Subscriberthank you for your answer.

Before I define the enthalpy as a APDL-command, I tryed many times to define it in engineering data (it is the easiest way to define it). but the result shows me that the mechnical solver does not take the enthalpy in consideration (I dont know why). Thatswhy I did it as a APDL- command.

Could it be that I have to change something in solver setting when I do a simulation of pcm ? or make something that I make it clear for the program, that I need the energy equation or I need to simulate a phase change? like is there any thing in the setting that I have extra to do or what would you suggest.

-

December 22, 2023 at 1:53 pm

Ata Sabra

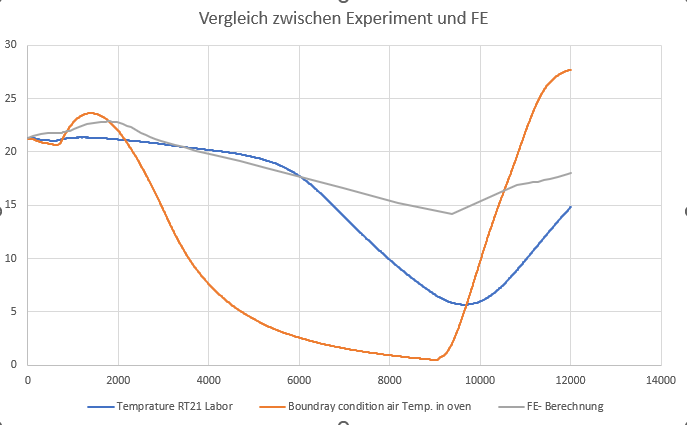

SubscriberIn labor I put the glas (with pcm inside) in the Oven for heating and cooling. first I Put the Oven temprature on 0 and start to masure the temprature inside the ofen and inside the glas (pcm- temprature). this is the data I have. So as boundry condition I have the temprature inside the oven and want the temprature of pcm as a result to make a validation.

What do you suggest to model the heat transfer in the oven (convection, Heat conduction) or something else. If you suggest convection what are typical values for the film coefficient inside a oven.

oven capacity is 1000W

-

December 22, 2023 at 3:08 pm

dlooman

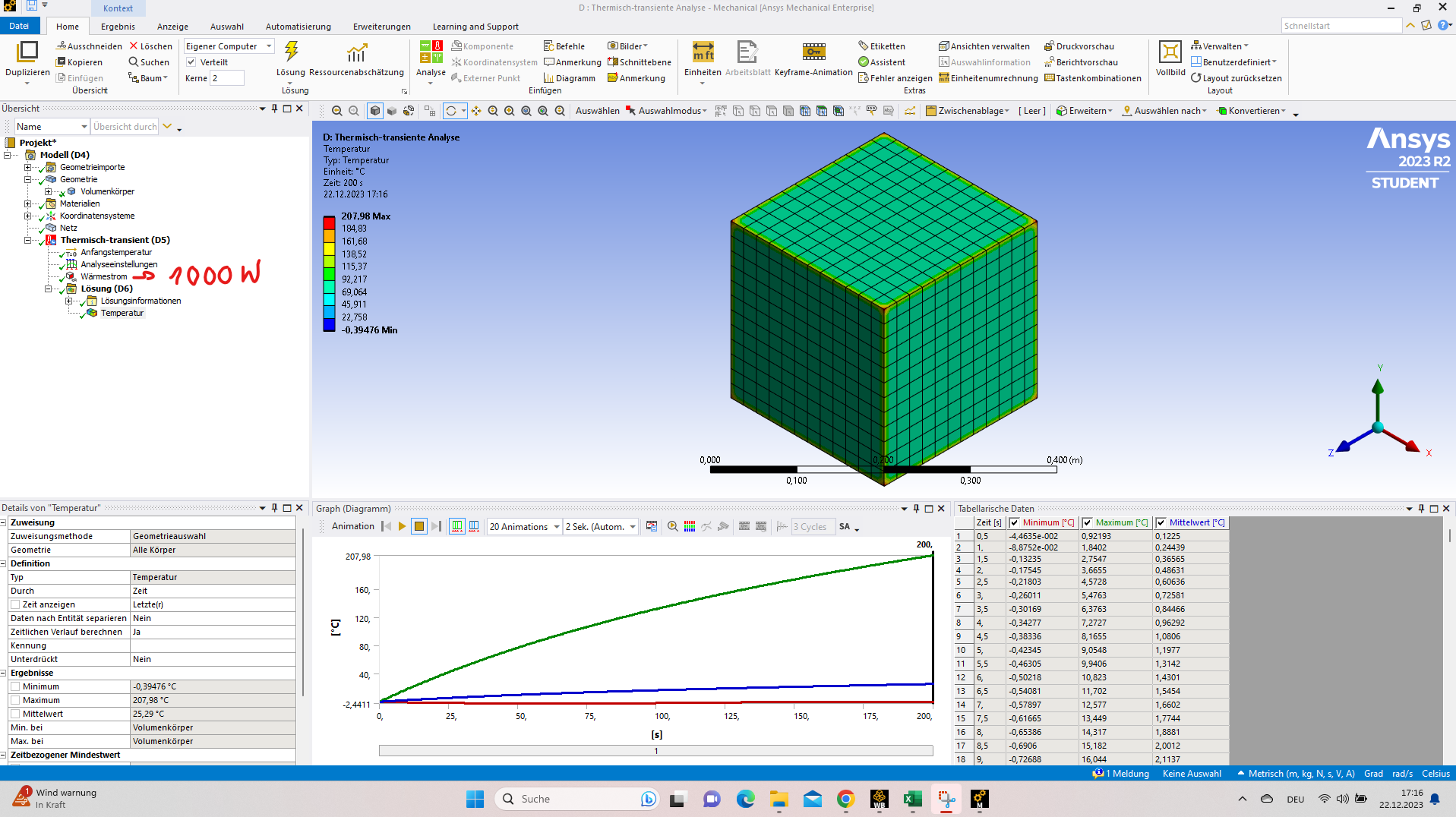

Ansys EmployeeIt's best to use MKS units for thermal. When you use a mm system the solver unit is mJ, even though the gui may use J units. Command input needs to be in solver units. I ran a test on a small cube with your enthalpy input below in a commands object and a 1000W applied heat rate. The temperature went from 0 to 18.5 deg in 34 secs, reached 21 deg in 182 secs and then 31.5 deg in 200 secs. Is this your expected temperature rise? I used a fixed time step of 0.5 secs to make sure the solver didn't jump past the step change in enthalpy.

mptemp,1,0,18.5,21,28

mpdata,enth,matid,1,0,3.4e7,1.82e8,1.94e8 -

December 22, 2023 at 4:02 pm

Ata Sabra

SubscriberMy problem is: as Input (boundray condition) I have the air temprature in the oven (as shown in the photo). How you recommend to input this temprature? as a convection ? heat conduction? or another thing.

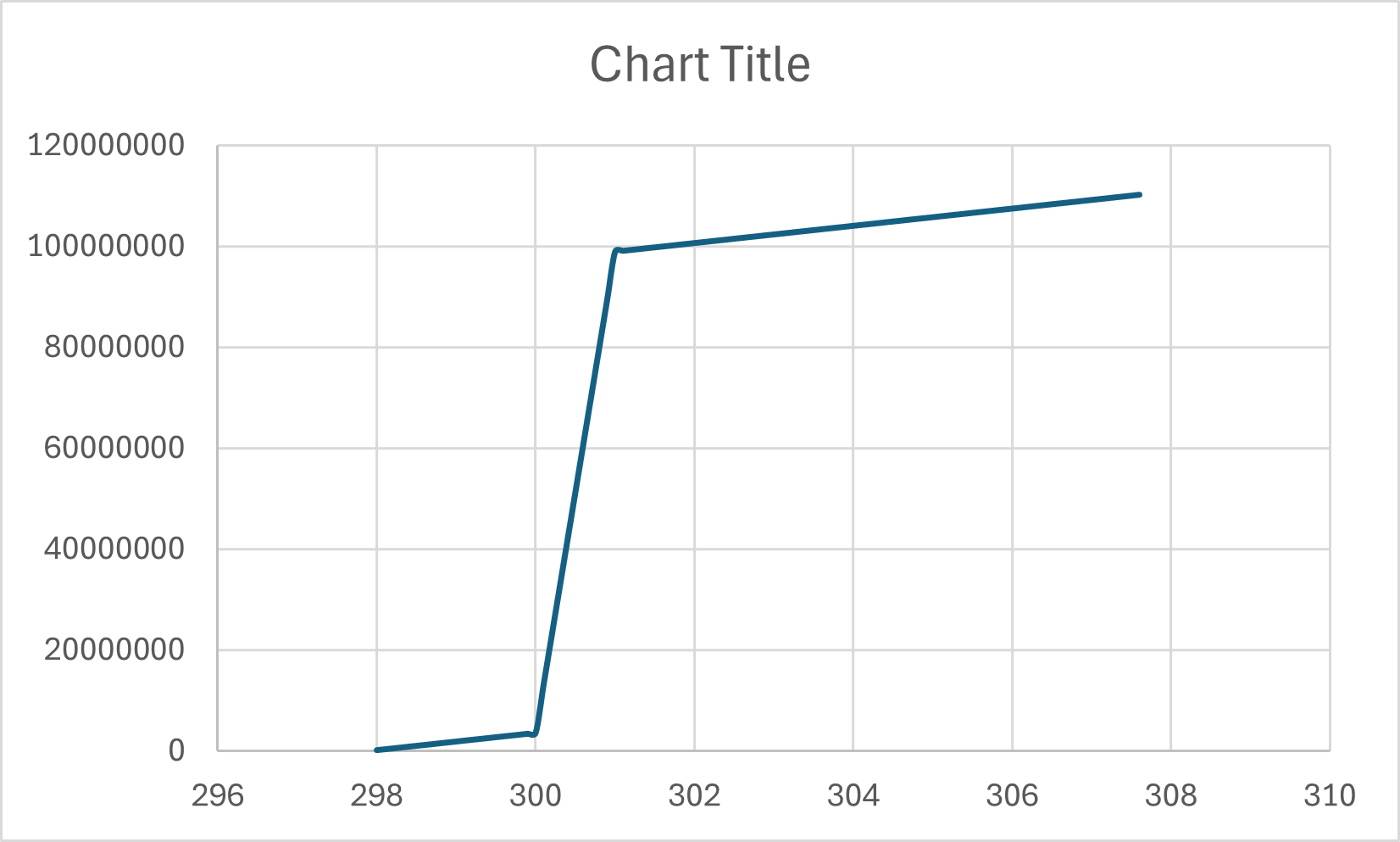

Till now I was putting the air temprature as a convection with the film coefficient 25 [W/m².°C] as input, and get the results as shown in the graph. they are far away from the results in the labor. even though I define all material properties and the geometry correctly. thatswhy I asked if I should change anything in the analysis setting or what do you think I am doing wrong.

-

December 22, 2023 at 4:17 pm

-

December 22, 2023 at 5:29 pm

dlooman

Ansys EmployeeI don't see a commands object in the tree. By specifying heat capacity (specific heat) you may be over-riding the enthalpy input.

-

December 22, 2023 at 5:52 pm

Ata Sabra

Subscriberthe command object is there but you dont see it because it is hidden with the minus. Anyway, Do you have answer for my questions above ? can I maybe send the boundray condition and the data on your email and you make a small similar simulation. It doesnt take much time only 10 min maximum.

Thank you in advanced

-

December 23, 2023 at 5:12 pm

dlooman

Ansys EmployeeIf the oven is pretty efficient you could specify a heat flux of 1000W divided by the model surface area. With convection the heat flow will change as the surface gets hotter. As a "sanity check" I created the one element test below. Could you try running it in the APDL gui as a test? With a heat generation rate load the body heats up uniformly so it's easier to evaluate the effect of the enthalpy curve since we have a one degree of freedom system.

/prep7et,1,279mp,kxx,1,1mp,dens,1,1 ! Dummy linear properties (Don't affect solution)mp,c,1,1mptemp,1,0,18.5,21,28mpdata,enth,1,1,0,3.4e7,1.82e8,1.94e8block,,.1,,.1,,.1esize,.1vmesh,1 ! One elementfini/soluantype,transic,all,temp,1 ! Start at a small no-zero temperaturebf,all,hgen,1e6 ! Load, 1000 Wtime,200autots,offdeltime,0.5outres,nsol,1cnvtol,heat,100,.01 ! Over-ride default convergence criterion which is near zero for unsupported model.lnsrch,on ! Line Search helps thermal convergencesolvefini/post26nsol,2,1,temp/show,pngplvar,2 ! Typical phase change temperature time-history -

December 24, 2023 at 2:56 pm

Ata Sabra

SubscriberI tryed to put the code in APDL but I coudnt understand so lot things because I had never work with it. I worked till now only with Ansys Workbench and did simple commands as APDL commands in Workbench

-

December 24, 2023 at 3:00 pm

Ata Sabra

SubscriberI can try to put a heat flux instead of convection. the only problem is the temprature in the oven is not constant and the air temprature inside the oven (which I have as a boundray condition) is changing with time

-

December 26, 2023 at 3:57 pm

dlooman

Ansys EmployeeYes, it's hard to accurately model an oven. Radiation can be signficant as well as convection. That's why if you know the oven is producing a heat rate of 1000 W, and most of that heat is going into the body being heated, it might be best to just specify the heat rate with a surface heat flux into the body.

It just occurred to me that the default transient thermal solver is the "Quasi" solver. This solver, sometimes referred to as the "fast solver," obtains improved performance by not reforming the thermal matrices every step. This could be why your enthalpy curve is being ignored. Try running your test with Analysis Settings> Nonlinear Controls> Nonlinear Formulation... set to "Full."

-

April 4, 2024 at 12:52 pm

Yash Patel

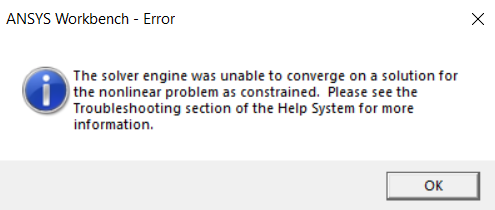

SubscriberI have been doing a similar analysis for a solid-solid phase transition material. I have been modelling the variation of SSPCM incorporate wall temperature with time. but I am facing an error : Property ENTH of material 1 is defined over a temperature range from 24.85 to 34.45 which does not include the uniform temperature (24.85). Change either temperature range or the uniform temperature. Checking for this condition discontinues. Due to this my solution isn't converging.

-

- The topic ‘Modeling of phase change materials’ is closed to new replies.

-

3622

-

1303

-

1122

-

1068

-

1008

© 2025 Copyright ANSYS, Inc. All rights reserved.