-

-

April 19, 2024 at 6:28 am

Wu PeiNan

Subscriber -

April 19, 2024 at 12:23 pm

Rob

Forum ModeratorYes, that will work.

-

April 19, 2024 at 2:17 pm

Wu PeiNan

SubscriberThanks for you replied, Rob.

When I choose a semi-closed pipe to simulate a methane explosion, I always fail to ignite in this model, why is that?

I used the simple pipe model, and I think if that there are any requirements for the mesh? Or which setting I ignore?

I would appreciate it.

-

April 19, 2024 at 3:08 pm

Ren

Ansys EmployeeCould you provide more details of what you are doing, for example,

geometry dimensions

combustion model

initial conditions

chemical mechanism

solver settings

-

April 19, 2024 at 4:24 pm

Wu PeiNan

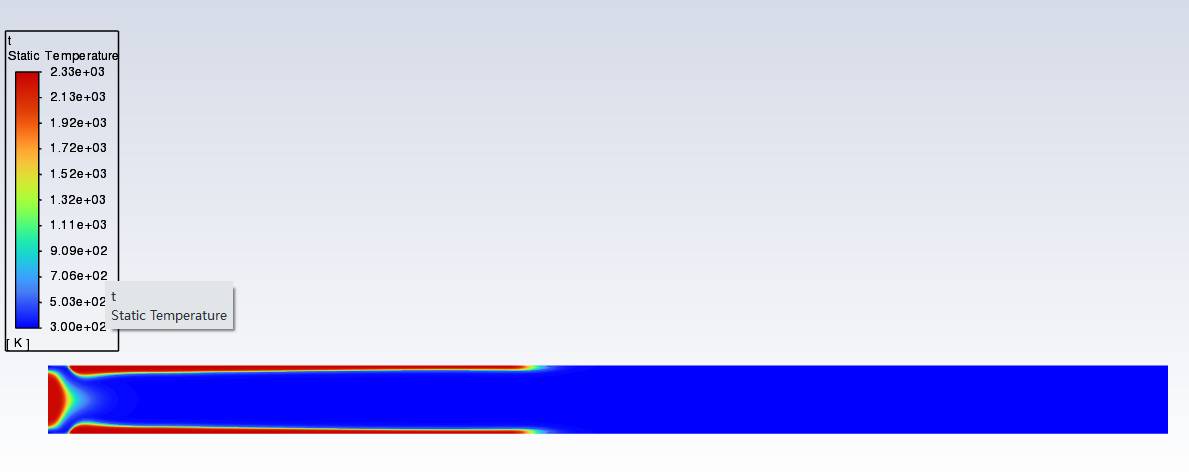

Subscriber The model is a rectangle pipe with length of 5 meters and width of 0.3 meters. The combustion model is the finite rate/eddy dissipation model, and its initial condition is shown as following figure, with the CH4 combustion reaction.

The model is a rectangle pipe with length of 5 meters and width of 0.3 meters. The combustion model is the finite rate/eddy dissipation model, and its initial condition is shown as following figure, with the CH4 combustion reaction.

For the solver, I choose pressure solver and simple algorithm with step of 0.005 seconds. -

April 22, 2024 at 2:39 pm

Ren

Ansys EmployeeSo what is your actual question?

-

April 22, 2024 at 3:55 pm

Wu PeiNan

Subscriber I can't light this model a lot of time, and even if I do, there will be irrational situations like this. I don't understand what is wrong with this. Is it the grid or a certain setting? Like this one, it lit up but the flame spread along the wall.

I can't light this model a lot of time, and even if I do, there will be irrational situations like this. I don't understand what is wrong with this. Is it the grid or a certain setting? Like this one, it lit up but the flame spread along the wall.Thanks for your response, this question has been bothering

me for a long time.

-

April 22, 2024 at 3:57 pm

Wu PeiNan

SubscriberOr do I need any additional setttings for ignition via patch to ensure that my model can simulate CH4 ignition and explosion?

-

April 23, 2024 at 2:16 pm

Ren

Ansys EmployeeHello,

- Is the pipe open-ended on both sides, or closed at one end and which end?

- If detonation is expected, I suggest you use the density-based solver (DBNS). The pressure-based solver (PBNS) should also work if the Mach numebr does not go very high.

- I suggest you use the "Finite-Rate/No TCI" option.

- Are you using a 1-step reaction scheme or multiple reaction scheme. For 1-step reaction, you need to patch a temperature and the composition that correspond to the burnt state of the mixture.

- The mesh needs to be sufficient fine around the flame front (and also shock wave). You can use automatic mesh refinement/coarsening

- The time step size also needs to be much smaller because everything goes very fast. I think 0.005 s is too large. It needs to be around 1E-5 s, or even smaller.

-

- The topic ‘Modeling Methane Explosion Ignition by Patch’ is closed to new replies.

-

3407

-

1057

-

1051

-

896

-

887

© 2025 Copyright ANSYS, Inc. All rights reserved.