-

-

August 16, 2023 at 11:00 am

J.Benavides

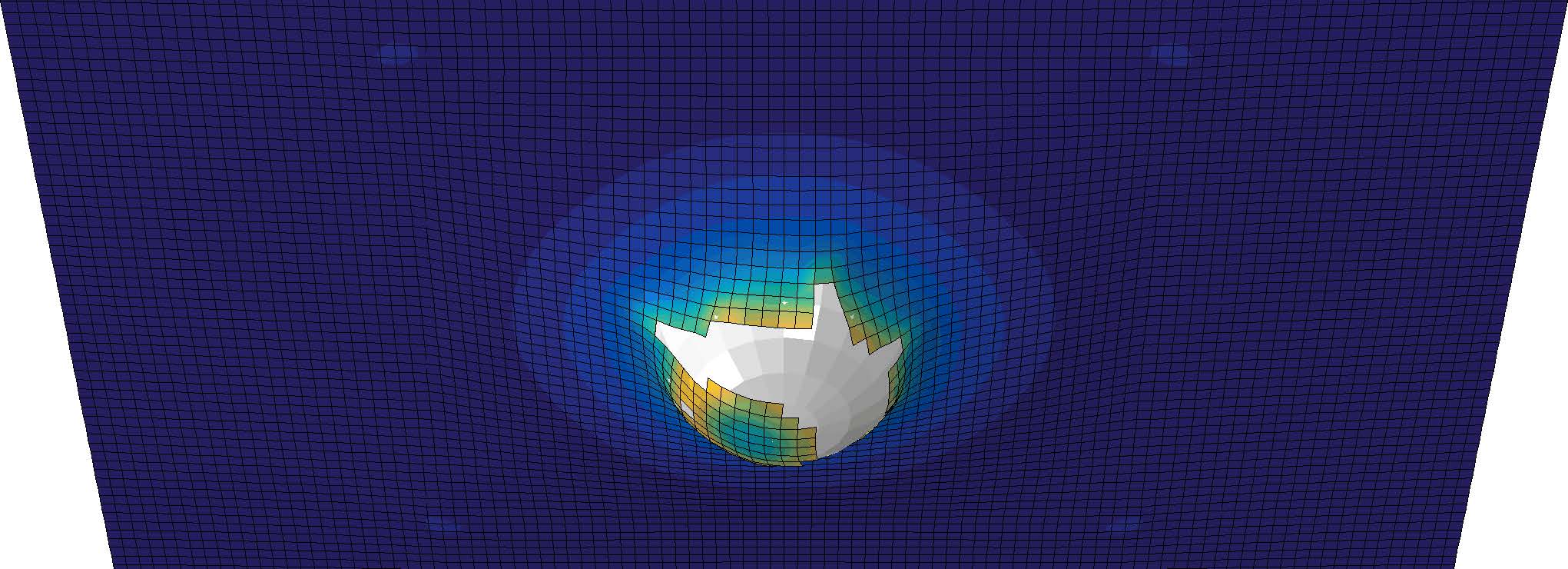

SubscriberHi, I need to replicate in Ansys APDL a simulation carried out in Abacus. For AS235 Steel material, the following simulation was carried out on a structure consisting of 2 plates separated by a certain distance and subjected to an impact. I must recreate the material damage simulation (See Photo). I have an uniaxial test of the material as data, I know that with this I could use a multilinear isotropic hardening curve up to plastic deformation without damage, but then I don't know how to represent the behavior after that, until the material breaks (the breakage of the material). Can someone help me or give me some guidance? Thank you for any help.

-

August 17, 2023 at 4:49 pm

Bill Bulat

Ansys EmployeeWas this analysis performed with Abaqus Explicit?

MAPDL technology is strictly implicit. Even if we "kill" (deactivate) elements (using the MAPDL EKILL command) as the solution progresses (using, say, some kind of limiting stress as a criterion for element deactivation), the deactivated elements are retained... they will continue to be used in the formulation of the system matrices. The failed elements will almost certainly become "entangled" - it will be impossible to formulate global stiffness matrix based on severely mishapen elements (e.g., vertices get pushed though element faces/edges on the opposite side). When that happens it's game over - the simulation will end with an element formulation error.

We have a couple of explicit solvers that are almost always much better suited to an impact + ultimate failure simulation such as this. They allow the specification of limiting failure stresses which, when exceeded, result in the elimination of the element entirely (so the simulation can proceed).

-

August 18, 2023 at 9:15 am

J.Benavides

SubscriberHi!

Thank you very much for your quick answer.

Yes, the simulation was performed with an explicit time integration, a quasi-static simulation. As additional information, can I mention that for the material model they use a hardening power of low for the plastic regime and a polynomial curve as function of plastic deformation for the damage evolution.

For the ansys MAPDL I already defined the impact through a contact pair and for the plate (Indenter: target 170 and contact surface: conta 174 elements) I use a shell element (shell 181) and for the material model I will define a multilinear isotropic hardening curve from the material data for the plastic regime but for the damage evolution and to generate the breaking of the steel plate, I don't know how it proceeds.

Which explicit solvers could I use to do this? I would really appreciate your help.

Thank you.

-

November 29, 2023 at 10:55 pm

Sebak Oli

SubscriberHi J.Benavides,

Did you find a way to solve the problem? I ran into the exact same problem. I do not know how to proceed after the necking point which is the damage/softening zone.

I am looking for help desperately. Any idea or suggestion would greatly help.

Thank You.

-

January 2, 2024 at 3:57 pm

Hassan Jishi

SubscriberI believe by explicit solver, they are referring to LS-Dyna.

I went through a similar problem when modeling the damage progression of composite material using implicit solver; ANSYS APDL.

I found it impossible to model the crushing of composite columns under axial compression. I tried element deletion, element property degradation, and like Bill Bulat said, it always ended up in error.

When moving on to LS-Dyna, crushing and deletion are pretty straight forward, however, I found it challenging to model quasi-static experiment conditions since LS-Dyna is mainly used for dynamic loading conditions, where material inertial effects come into play.

However, it is possible to tune certain parameters to simulate a quasi-static loading condition in LS-Dyna. Given the time limitations at the time (PhD thesis deadline), I didn’t complete my explicit analysis.

I can share some information/papers if interested. Let me know.

Best regards,

Hassan Jishi

-

January 24, 2024 at 7:43 am

Sebak Oli

SubscriberHi Hassan Jishi,

I have written a usermat for matrix and inclusions which also include damage. So at some displacement those material will lose all stiffness (Just like ekill, I guess) but when I combine them as a composite and apply displacement, I get element distortion issue. No matter what I do I am not getting softening curve for the composite in APDL. Let alone the softening curve, I can't even apply tiny displacement. I am not sure if I should perform analysis in LS-Dyna or there is a way to resolve the issue of distortion element. If you could provide anything related to APDL or LS-Dyna or any other materials to study, it would be helpful. I really appreciate the suggestion.

Regards,

Sebak Oli

-

-

January 8, 2024 at 10:52 pm

Sergio Abril

Subscriber

-

- The topic ‘Material Damge Model’ is closed to new replies.

-

3467

-

1057

-

1051

-

918

-

896

© 2025 Copyright ANSYS, Inc. All rights reserved.