TAGGED: design-optimization, implicit, ls-dyna, ls-opt

-

-

November 3, 2024 at 2:21 pm

fabian.duckhorn

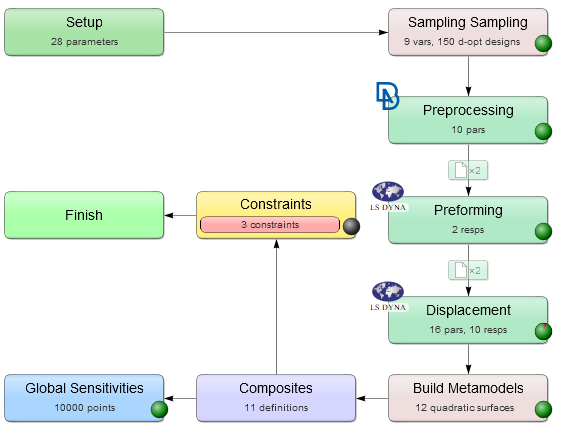

SubscriberHello, I´m new to Ls-Opt and i want to make an Optimization for a Buckling Simulation of a sandwich panel.

As a start i want to detemin the sensitivities of the parameters with an DOE study. However even with a quadric order the accuracy of the polynomial metamodell for the force output is at 46% (RMS Error). I used the D-Optimal point selection with default settings and 150 points on 9 variables for this. In the accuracy plot i can see that many experiments are being predicted with positiv force values which leaves me questioning if it is possible to set the model so the maximum value can only be 0 ? I find it also interesting that the positive input forces on the other end of the panel which are introduced by a prescribed motion are being predicted very well with only 7-10% RMS Error. Togehther their sum equals the force otput. If anyone has ideas on this please let me know.

-

November 4, 2024 at 3:55 pm

igandiko

Ansys Employee"many experiments are being predicted with positiv force values"-- how are the computed response values of the design points, all negative? Model could be predicting positives values because some computed design responses were positive.

Have you tried an advanced metamodel? RBF, NN? You can go to sampling box -> comparision metamodel -> add a few other metamodels, then tools -> repair -> build metamodels, and then compare them using the accuracy plots.

Note that for a DOE run, space filling sampling with RBF/NN could be better. If you want to run an optimization, change the task to SRSM (iterative domain reduction) and the metamodel accuracy will improve as the domain is reduced after each iteration in search of an optimum design.

-

- You must be logged in to reply to this topic.

-

3367

-

1050

-

1047

-

886

-

837

© 2025 Copyright ANSYS, Inc. All rights reserved.