TAGGED: -LS-DYNA-run-time, ansys-ls-dyna, ls-dyna

-

-

July 24, 2024 at 10:26 pm

JASH RANA

SubscriberHi Forum,

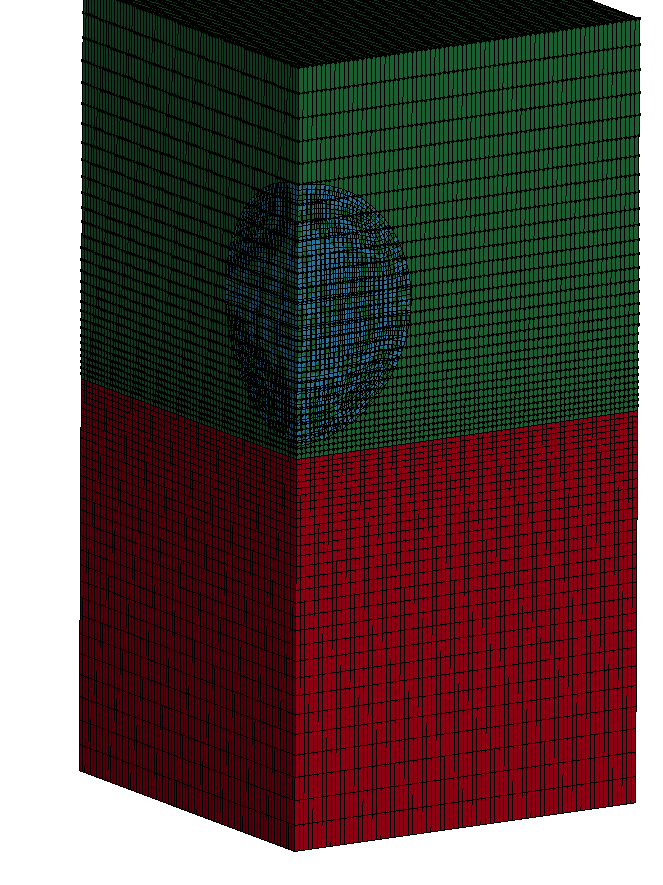

I am trying to run a simulation where I have an aluminum particle impacting an aluminum substrate. I want both as ALE since they experience high distortion in lagrangian as well as premature termination. I am not sure if my current implmentation is correct. When I run the simulation both my particle and substrate dissapear and I get this warning:

*** Warning 40864 (SOL+864)

Segment based contact stiffness was reduced due to

an increasing solution time step. The new time step for

the stiffness calculation is 1.2952E-08And this error:

*** Error 40509 (SOL+509)

negative volume in solid element # 193650 cycle 688*** Error 40509 (SOL+509)

negative volume in solid element # 193650 cycle 688

Any help on implementing ALE into my model would be much appreciated. Thanks in advance. I have attached my model for your reference. -

July 25, 2024 at 2:16 pm

Ian Do

Ansys EmployeeHi Jash,

ELFORM=5 is obsolete. Please use ELFORM=11. And you must provide the extra empty ALE space around the mat that is deforming. This space can be filled with air or mat_vacuum. Before using ALE, it would save time if you can review the ALE class on ANSYS Learning Hub (ALH). There are may examples available there also. What you see is likely the result of locally very strong force combining with large dt that invert the elm. You may need to look at tuning either one or both.

Regards,

Ian Do

-

July 25, 2024 at 3:35 pm

JASH RANA

SubscriberHi Ian,

Thank you for the reply. I don't believe my institution has a subscribtion to ALH. Do I need to provide empty space for both the substrate and particle? or just the particle? Do you have an example keyword file that contains a similar problem to mine (impactor and target both ALE)?Regards,

Jash

-

July 31, 2024 at 9:28 pm

Ian Do

Ansys EmployeeHi Jash,

This may be similar (I can't attach a file so i just put it here.) Anyway, ALE is difficult and you likely need a class. I can't teach it through this communication channel.

*KEYWORD

*TITLE

saleimpact3b.k = kg-m-s-K - pls assume fictitious data & put in your own referened data.

$===============================================================================

*COMMENT

Model Summary:

H4 = AMMG1 = impactor

H2 = AMMG2 = top plate

H1 = AMMG3 = bottom plate

$===============================================================================

$ [ ] EXECUTION CONTROLS

$===============================================================================

*CONTROL_TERMINATION

$# endtim endcyc dtmin endeng endmas nosol

$ 2.5E-4 0 0.0 0.0 0.0 0

10.0E-4 0 0.0 0.0 0.0 0

*CONTROL_TIMESTEP

$# dtinit tssfac isdo tslimt dt2ms lctm erode ms1st

0.0 0.7 0 0.0 0.0 0 0 0

$ 0.0 0.2 0 0.0 0.0 0 0 0

$# dt2msf dt2mslc imscl unused unused rmscl

0.0 0 0 0.0

*CONTROL_CONTACT

$# slsfac rwpnal islchk shlthk penopt thkchg orien enmass

0.1 0.0 1 0 1 0 1 0

$# usrstr usrfrc nsbcs interm xpene ssthk ecdt tiedprj

0 0 10 0 4.0 0 1 0

$# sfric dfric edc vfc th th_sf pen_sf

0.0 0.0 0.0 0.0 0.0 0.0 0.0

$# ignore frceng skiprwg outseg spotstp spotdel spothin

0 0 0 0 0 0 0.0

$# isym nserod rwgaps rwgdth rwksf icov swradf ithoff

0 0 1 0.0 1.0 0 0.0 0

$# shledg pstiff ithcnt tdcnof ftall unused shltrw

0 0 0 0 0 0.0

*CONTROL_CPU

$# cputim

0.0

*CONTROL_ENERGY

$# hgen rwen slnten rylen

2 2 2 2

*CONTROL_OUTPUT

$# npopt neecho nrefup iaccop opifs ipnint ikedit iflush

0 0 0 0 0.0 0 100 9000

$# iprtf ierode tet10s8 msgmax ipcurv gmdt ip1dblt eocs

0 0 2 50 0 0.0 0 0

$# tolev newleg frfreq minfo solsig msgflg cdetol

2 0 1 0 0 0 10.0

$# phschng demden

0 0

$===============================================================================

$ [ ] OUTPUT CONTROLS

$===============================================================================

*DATABASE_BINARY_D3PLOT

$# dt lcdt beam npltc psetid

1.0E-5 0 0 100 0

$# ioopt

0

$===============================================================================

$ [ ] |PART_ID|SECTION_ID|MAT_ID|EOS_ID|HG_ID|GRAV|ADPOPT|THERM_MID| DEFINITIONS

$===============================================================================

*PART

H1 = AMMG4 = Thick bottom Plate - A36 SS -Johnson Cook - kg-m-s-K

$# pid secid mid eosid hgid grav adpopt tmid

$ 1 1 1 1 0 0 0 0

1 1 12 12 0 0 0 0

*SECTION_ALE2D

$ secid1 aleform aet elform

1 11 14

*MAT_JOHNSON_COOK

$# mid ro g e pr dtf vp rateop

1 7890.07.80000E102.00000E11 0.26 0.0 0.0 0.0

$# a b n c m tm tr epso

2.861000E85.000000E8 0.2282 0.022 0.917 1811.0 293.15 1.0

$# cp pc spall it d1 d2 d3 d4

481.0 0.0 2.0 0.0 0.0 0.0 0.0 0.0

$# d5 c2/p erod efmin

0.0 0.0 01.00000E-6

*EOS_GRUNEISEN

$# eosid c s1 s2 s3 gamao a e0

1 4569.0 1.49 0.0 0.0 2.17 0.0 0.0

$# v0

0.0

$-------------------------------------------------------------------------------

*PART

H2 = AMMG3 = top Plate - Lexan-Johnson Cook - kg-m-s-K

$# pid secid mid eosid hgid grav adpopt tmid

$ 2 1 2 2 0 0 0 0

2 1 12 12 0 0 0 0

$ 2 1 22 0 0 0 0 0

*MAT_JOHNSON_COOK

$# mid ro g e pr dtf vp rateop

2 1190.07.860000E82.540000E9 0.344 0.0 0.0 0.0

$# a b n c m tm tr epso

7.580000E76.890000E7 1.004 0.0 1.85 533.0 293.15 1.0

$# cp pc spall it d1 d2 d3 d4

1250.0 0.0 2.0 0.0 0.0 0.0 0.0 0.0

$# d5 c2/p erod efmin

0.0 0.0 01.00000E-6

*EOS_GRUNEISEN

$# eosid c s1 s2 s3 gamao a e0

2 1933.0 1.42 0.0 0.0 0.61 0.0 0.0

$# v0

0.0

$-------------------------------------------------------------------------------

*MAT_ELASTIC

$ MID RHO E PR DA DB K

22 1190.0 2.54E9 0.344

$-------------------------------------------------------------------------------

*MAT_JOHNSON_COOK

$ MID RO G E PR DTF VP - Cu

12 8960.0 0.460E11 0.0 0.34

$ A B n C m Tm Tr eps0

90.0E6 292.0E6 0.310 0.0250 1.09 1356.0 293.00 1.0

$ Cp Pc Spall IT d1 d2 d3 d4

383.0 -1.2E6 2.0 0.000 0.540 4.89 3.03 0.0140

$ d5

1.12

*EOS_GRUNEISEN

$ EOSID C S1 S2 S3 GAMMA A E0

12 3940.0 1.489 0.0 0.0 2.020 0.47 0.0

$ VO

0.0

$-------------------------------------------------------------------------------

*PART

H4 = AMMG2 = Impactor - JOHNSON_HOLMQUIST_CERAMICS - Float glass-Borosilicate

$# pid secid mid eosid hgid grav adpopt tmid

$ 4 1 4 0 0 0 0 0

4 1 14 14 0 0 0 0

$ 4 1 24 0 0 0 0 0

*MAT_JOHNSON_HOLMQUIST_CERAMICS

$# mid ro g a b c m n

4 2500.03.04000E10 0.93 0.88 0.003 0.35 0.77

$# epsi t sfmax hel phel beta

1.01.500000E82.975000E95.950000E92.920000E9 1.0

$# d1 d2 k1 k2 k3 fs

0.053 0.854.54000E10-1.3800E112.90000E11 0.0

*EOS_GRUNEISEN

$# eosid c s1 s2 s3 gamao a e0

4 4710.0 1.0 0.0 0.0 1.0 0.0 0.0

$# v0

0.0

$-------------------------------------------------------------------------------

*MAT_ELASTIC

$ MID RHO E PR DA DB K

24 7840.0 210.0e+9 0.3

$---5----0----5----0----5----0----5----0----5----0----5----0----5----0----5----0

*MAT_JOHNSON_COOK

$ MID RHO G E PR DTF VP - SS

14 7840.0 80.0E+9 210.0e+9 0.3 0.0 0.0

$ A B n C m Tm Tr EPSO

792.19e6 509.51e6 0.26 0.014 1.03 1793.15 298.15 1

$ Cp PC spall IT D1 D2 D3 D4

477 -1.0e8 0.0 0.0 -8.0e-1 2.1e00 -5.0e-1 2.0e-3

$ D5

6.1e-1

*EOS_GRUNEISEN

14 4.570E3 1.49 0.0 0.0 1.930 0.0 0.0

$ VO

0.0

$-------------------------------------------------------------------------------

*PART

H5 = AMMG1 = air (Kg-m-s-K) @ T = 25 C

$# pid secid mid eosid hgid grav adpopt tmid

$ 5 1 5 5 0 0 0 0

5 1 6 0 0 0 0 0

*MAT_NULL

$ MID RO PC MU TEROD CEROD YMBEAM PRBEAM

5 1.1845 -1.0 1.8444E-5 0.0 0.0 0.0 0.0

*EOS_LINEAR_POLYNOMIAL

$ EOSID C0 C1 C2 C3 C4 C5 C6

5 0.0 0 0 0 0.4 0.4 0

$ E0 V0

2.533125E5 1.0

$---5----0----5----0----5----0----5----0----5----0----5----0----5----0----5----0

*COMMENT

PART

H6 = AMMG5 = vacuum

$# pid secid mid eosid hgid grav adpopt tmid

6 1 6 0 0 0 0 0

*MAT_VACUUM

$ MID RO PC MU TEROD CEROD YMBEAM PRBEAM

6 1.0E-06

$===============================================================================

$ SALE

$===============================================================================

*ALE_STRUCTURED_MESH

$# mshid dpid nbid ebid tdeath

11 11 20001 20001

$# cpidx cpidy cpidz nid0 lcsid

101 102

$-------------------------------------------------------------------------------

*ALE_STRUCTURED_MESH_CONTROL_POINTS

$# cpid sfo offo

101 1.0 0.0

$# n x ratio

1 0.0

201 0.4

$ 401 0.4

*ALE_STRUCTURED_MESH_CONTROL_POINTS

$# cpid sfo offo

102 1.0 0.0

$# n x ratio

1 0.0

186 0.370

$ 371 0.370

$===============================================================================

*CONTROL_ALE

$# dct nadv meth afac bfac cfac dfac efac

-1 1 2 -1.0 0.0 0.0 0.0 0.0

$# start end aafac vfact prit ebc pref nsidebc

$ 0.0 0.0 0.0 0.0 0 0 101325.0 0

0.0 0.0 0.0 0.0 0 0 0.0 0

$# ncpl nbkt imascl checkr beamin mmgpref pdifmx dtmufac

1 50 0 0.0 0.0 0 0.0 0.0

$# optimpp ialedr bndflx minmas

0 0 01.00000E-5

$-------------------------------------------------------------------------------

*ALE_MULTI-MATERIAL_GROUP

$# sid idtype gpname

5 1 1airvac

4 1 2impactor

2 1 3topplate

1 1 4botplate

$ 6 1 5vac

$-------------------------------------------------------------------------------

*ALE_STRUCTURED_MESH_VOLUME_FILLING

$# mshid unused ammgto unused nsample unused unused vid

11 1 4 0

$# geom in/out e1 e2 e3 e4 e5

ALL 0 0.0 0.0 0.0 0.0 0.0

$-------------------------------------------------------------------------------

*ALE_STRUCTURED_MESH_VOLUME_FILLING

$ MSHID notused AMMGTO notused NSAMPLE notused notused VID

11 2 4 51

$ 11 2 4

$ geom in/out E1=CTRNID E2=rx E3=ry R4=rz E5=lcsid

ELLIPSOID 0 11 0.05 0.05 0.00 0

*DEFINE_VECTOR

$ vid xt=velx yt=vely zt=velz

51 0.0 -50.0 0.0

*NODE

$ NID X Y Z TC RC

11 0.0 0.31 0.0

$-------------------------------------------------------------------------------

$ center: Xc=0.0, Yc=0.31, Zc=0.0 , R=0.05

$===============================================================================

*ALE_STRUCTURED_MESH_VOLUME_FILLING

$ MSHID notused AMMGTO notused NSAMPLE notused notused VID

11 3 4

$ GEOM IN/OUT E1=BOXID E2 E3 E4 E5

BOXCOR 0 2

*DEFINE_BOX

$ BOXID XMN XMX YMN YMX ZMN ZMX

2 0.0 0.4 0.2 0.256 0.0 0.01

$-------------------------------------------------------------------------------

$ SALE mesh box: (0.0,0.2,0.0)-(0.4,0.256,0.0), dx=0.002

$===============================================================================

*ALE_STRUCTURED_MESH_VOLUME_FILLING

$ MSHID notused AMMGTO notused NSAMPLE notused notused VID

11 4 4

$ GEOM IN/OUT E1=BOXID E2 E3 E4 E5

BOXCOR 0 3

*DEFINE_BOX

$ BOXID XMN XMX YMN YMX ZMN ZMX

3 0.0 0.4 0.0 0.2 0.0 0.01

$-------------------------------------------------------------------------------

$ SALE mesh box: (0.0,0.0,0.0)-(0.4,0.2,0.0), dx=0.002

$-------------------------------------------------------------------------------

*SET_MULTI

201

1

*SET_MULTI

202

2

$-------------------------------------------------------------------------------

*DEFINE_CURVE

$# lcid sidr sfa sfo offa offo dattyp lcint

2 0 1.0 1.0

$# a1 o1

0.0000 0.0

0.1000 1.e7

$===============================================================================

$ [ ] BC's + IC's + BODY LOADS + FORCE FIELDS

$===============================================================================

*BOUNDARY_SPC_SET

$ nodeset1 cid dofx dofy dofz dofrx dofry dofrz

1 0 1 1 1

2 0 1 1 1

$-------------------------------------------------------------------------------

*SET_NODE_GENERAL

$ SID

1

$ OPTION MSHID XMN XMX YMN YMX ZMN ZMX

SALEFAC 11 1

$-------------------------------------------------------------------------------

*SET_NODE_GENERAL

$ SID

2

$ OPTION MSHID XMN XMX YMN YMX ZMN ZMX

SALEFAC 11 1

$===============================================================================

*END

$===============================================================================

-

- The topic ‘LS DYNA Simulation where both impactor and target are ALE [HELP REQUEST]’ is closed to new replies.

-

5159

-

1836

-

1387

-

1249

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.