-

-

May 14, 2025 at 11:32 am

-

May 14, 2025 at 1:09 pm

Armin

Ansys EmployeeHello,

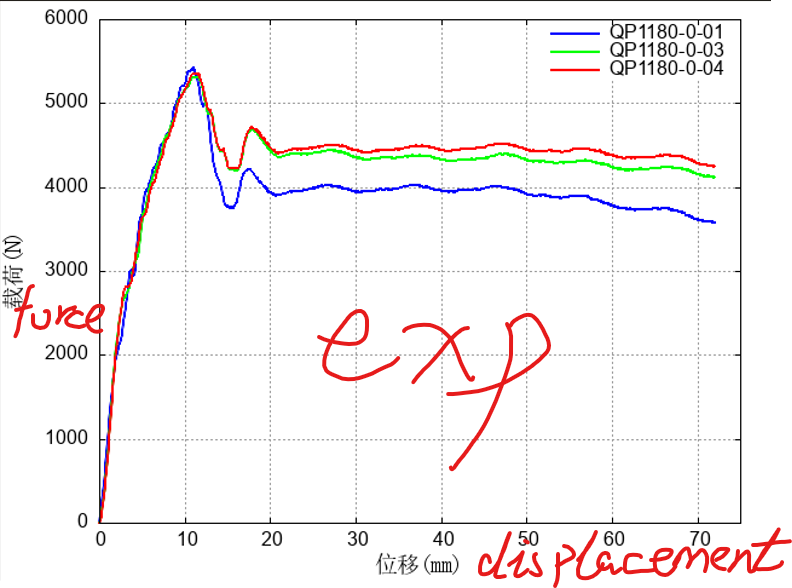

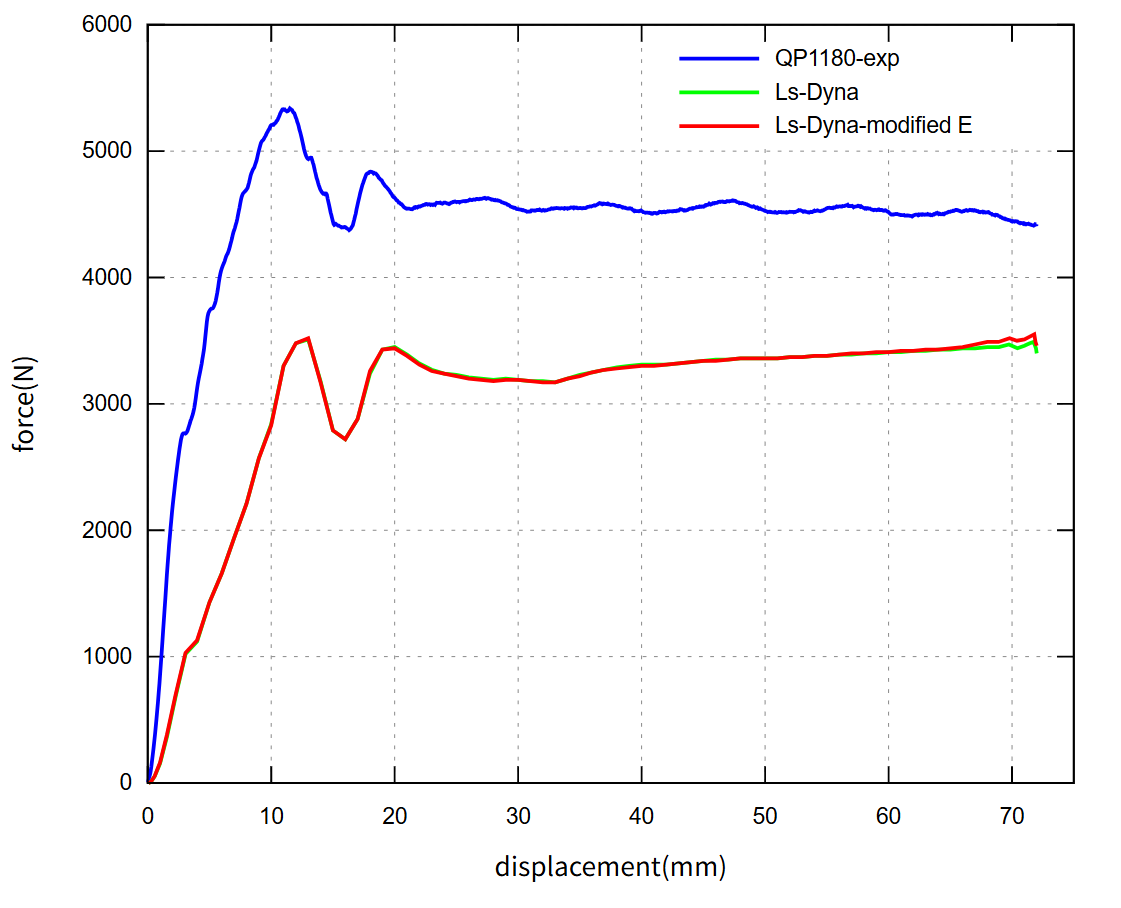

Please overlay the two plots into one, focusing on force versus displacement, so that it will be easier to compare them. Since there are not many details provided, I can offer some general suggestions:- Once the two curves are overlaid, compare the initial (relatively linear) portion of the response. Inconsistencies in this area may indicate issues with the elastic properties.

- I expect plastic deformation to initiate somewhere within the larger deformation range. You should examine the plasticity properties in that range.

- Additionally, friction between the specimen and the tool can influence the results and should be verified.

-

May 15, 2025 at 6:27 am

891348308

SubscriberHi, Armin

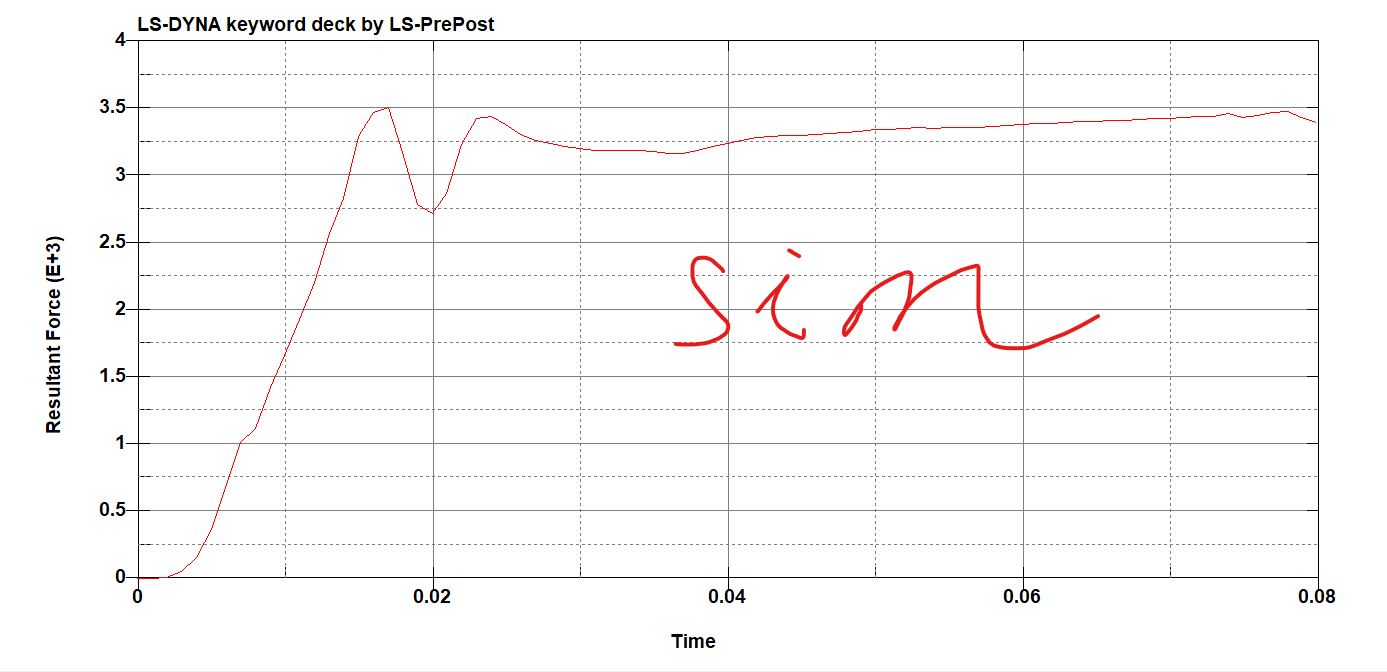

Thank you for your helpful advice! I overlaied the two curves and found the linear part inconsistent, I tried to modify the young's modulus and the friction factor between punch and sheet, but it didn't seem to improve the situation. What else can I check or is there anything in the output file I can check to better understand the situation?

I'm looking forward to your professional advice and thank you for your patience!

-

May 15, 2025 at 2:17 pm

Armin

Ansys EmployeeThank you for making the comparison.

In addition to verifying that the imposed boundary conditions align with the actual experiments, another factor you can check to resolve the initial linear part is ensuring that the bending of the specimen is accurately captured in the model. For example, if you're using solid elements, you need a sufficient number of elements through the thickness of the sheet to accurately capture the bending mode. For shells, you need a sufficient number of integration points through the thickness.

-

-

- You must be logged in to reply to this topic.

-

3622

-

1303

-

1122

-

1068

-

1008

© 2025 Copyright ANSYS, Inc. All rights reserved.