-

-

February 27, 2021 at 7:56 pm

Evgenii_K

SubscriberHello everyone!nI solve a problem with thin shells, with a static calculation I have no problems, when I connect large defomations, I have no solution convergence. How can convergence be improved or what could be the problem?n -

February 27, 2021 at 11:46 pm

peteroznewman

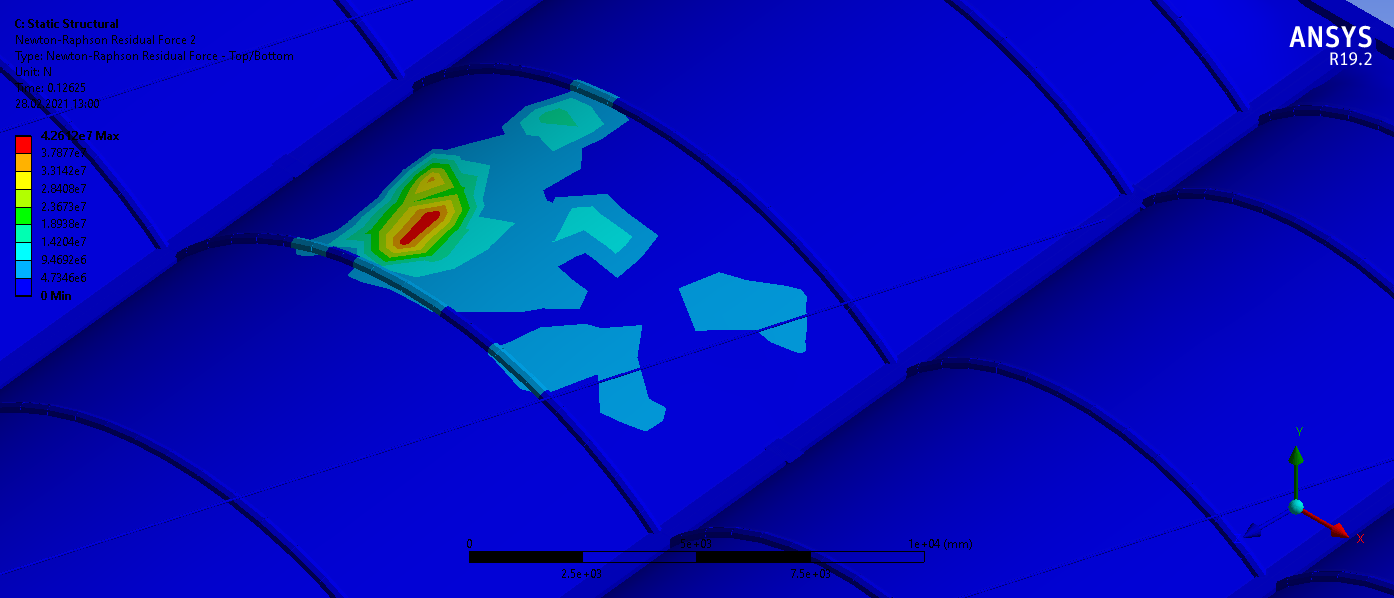

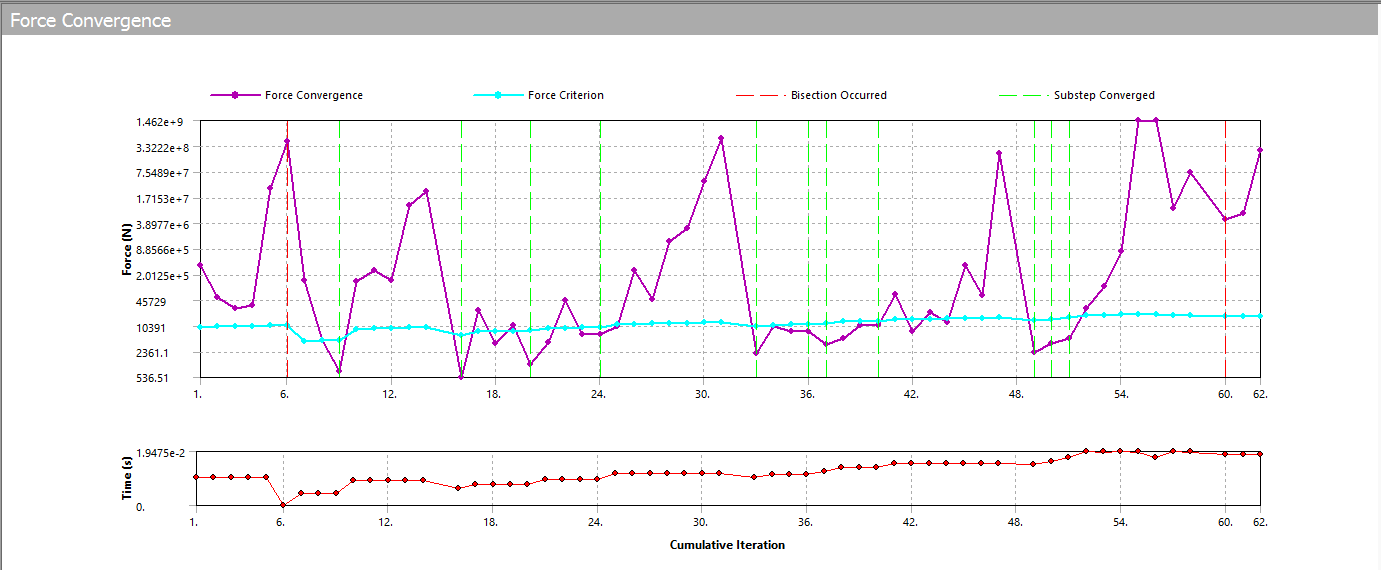

SubscribernUnder Analysis Settings, turn on Large Deflection. Turn on Auto Time Stepping. Set the Initial and Minimum Substeps to 100, and the Maximum Substeps to 1000.nClick on the Solution Information folder and type 3 into the Newton-Raphson Residual plots in case you fail to converge.nReply with an image of the Newton-Raphson Convergence Plot.n -

February 28, 2021 at 10:07 am

-

February 28, 2021 at 1:02 pm

peteroznewman

SubscribernDo you have contact in the model? If so, reducing the Normal Stiffness of the contact by a factor of 0.1 can help convergence.nThe N-R Residual Force plots show you where to improve the mesh. Use smaller elements at these locations.nPlease show the mesh at these locations before and after the mesh improvement. Are these shell or solid elements?n -

February 28, 2021 at 6:25 pm

Evgenii_K

SubscriberThere are no contacts in the model!nResidual force NR is displayed over the entire model shell.nThe shell in the modoli is broken with a 1000 mm mesh.nThis is - SHELL181; keyopt=1nIt became impossible to solve the whole model with a 100 mm grid, so I made a test model with one span. But even a solution with such a fine grid could not be found.nThe grid that was before - 1000 mmn Mesh which has become - 100 mmn

Mesh which has become - 100 mmn

n

n

-

March 1, 2021 at 3:53 am

peteroznewman

SubscribernPlease describe the loads and supports on the shell.nIf there is a pressure on the convex side or a large compressive load in the membrane direction of the shell, then the reason for the lack of convergence could be due to the load approaching a buckling load. That can be a reason why a Static Structural model will converge with Large Deflection turned off, but will fail to converge with Large Deflection turned on. The structure becomes unstable as the load approaches the instability. With stabilization or arc-length methods, the solution can proceed past the critical load and show post-buckled results.nBuckling can also be mesh dependent, and we see some evidence of that since the coarse mesh got a little further than the fine mesh.n -

March 1, 2021 at 5:51 am

Evgenii_K

SubscriberYou are absolutely right! The casing consists of a technical fabric 1 mm thick (the fabric is very strong and can withstand heavy loads) stretched over a steel frame, a static load is applied to the casing - pressure. Is there a way to solve this convergence problem?n -

March 2, 2021 at 9:54 pm

peteroznewman

SubscribernGetting a structure with an applied pressure to show post-buckled results is challenging. Get ready for days (weeks?) of research. One requirement is to introduce some tiny amount of non-uniformity into the model to seed the buckled shape. This can be done by reshaping the geometry with a small amount of the linear elastic buckled shape, or you can apply a small force that will help it to buckle. Here is a YouTube video that explains that.nhttps://www.youtube.com/watch?v=j_hdimE35hsnYou can learn something about the critical buckling load and the buckled shape using the linear Eigenvalue Buckling analysis. nStart by taking the Structural Instabilities Course.n/courses/index.php/courses/structural-instabilities/nHere are the discussions on linear Eigenvalue Bucklingnhttps://www.google.com/search?q=site%3Aforum.ansys.com+eigenvalue+buckling&oq=site%3Aforum.ansys.com+eigenvalue+bucklingnHere are the discussions on nonlinear post buckled analysis.nhttps://www.google.com/search?q=site%3Aforum.ansys.com+nonlinear+post+buckling+stabilization+arc-length&oq=site%3Aforum.ansys.com+nonlinear+post+buckling+stabilization+arc-lengthn -

March 3, 2021 at 5:51 pm

Evgenii_K

SubscriberI already studied this problem and came to the conclusion that it can be solved using Hill's fluidity, I even asked a question on this forum about how Hill's theory can be applied, I wrote to technical support, and wrote on other forums, no one could give an even answer. Your answer about how you can solve this problem is the most complete and fairly objective.n -

March 3, 2021 at 6:48 pm

-

March 4, 2021 at 7:52 pm

peteroznewman

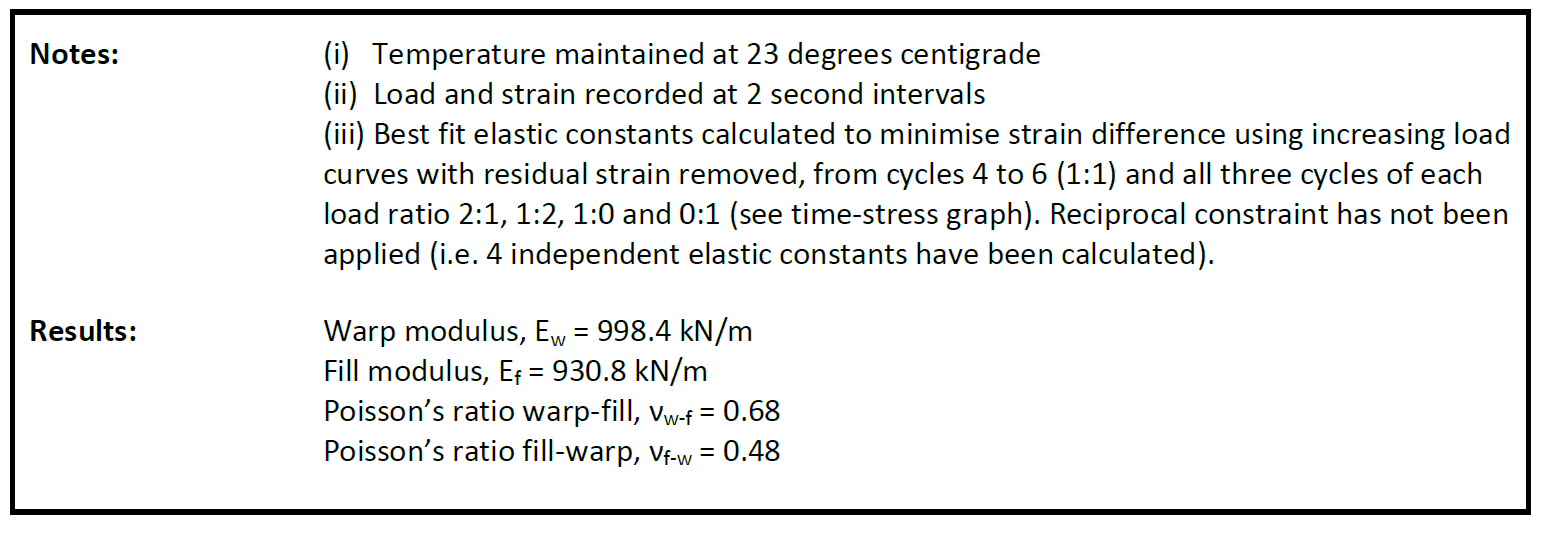

SubscribernOn sheet 1 I can see the UTS, but what you want is the Modulus. Do you have a copy of MSAJ/M-02-1995 to see how that test is performed?n -

March 4, 2021 at 8:12 pm

-

March 5, 2021 at 4:49 am

peteroznewman

SubscribernThis is a woven fabric, so there are different properties in the Warp and Fill directions.nWhat is the sheet thickness?nWhat is the fiber material?nWhat is the binder material?nDo you have the material properties of the fiber and binder?nANSYS has ACP/Pre that allows you to define a composite material and put fibers down in two directions and hold them together with a binder.n -

March 5, 2021 at 5:51 am

Evgenii_K

SubscriberACP / Pre, I have already checked it will not work. To solve the problem, I need to convert the units of measurement to MPa and assign the properties of the material in the third direction. But those properties of the material that I have, they are not required for Hill's fluidity, for this task the stresses radiated during stretching and sliding are needed, and this experiment must be done three times, but I only have this data with them and I need to work with them. The question is, how can the experimental data be reduced to MPa and is it possible to take voltages from the diagram ?! The diagrams that in the report I converted into an electronic version and tried to use them in the model of hyperelastic materials, but here too, failure.nMaterial thickness 1 mm, base material polymer reinforced with fiberglass meshn

-

Viewing 13 reply threads

- The topic ‘Large Deflection’ is closed to new replies.

Innovation Space

Trending discussions

Top Contributors

-

4939

-

1639

-

1386

-

1242

-

1021

Top Rated Tags

© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.