TAGGED: ansys-mechanical, hexahedral-mesh, meshing, tetrahedral, uniform

-

-

December 4, 2023 at 12:58 am

jwyatteckstrom

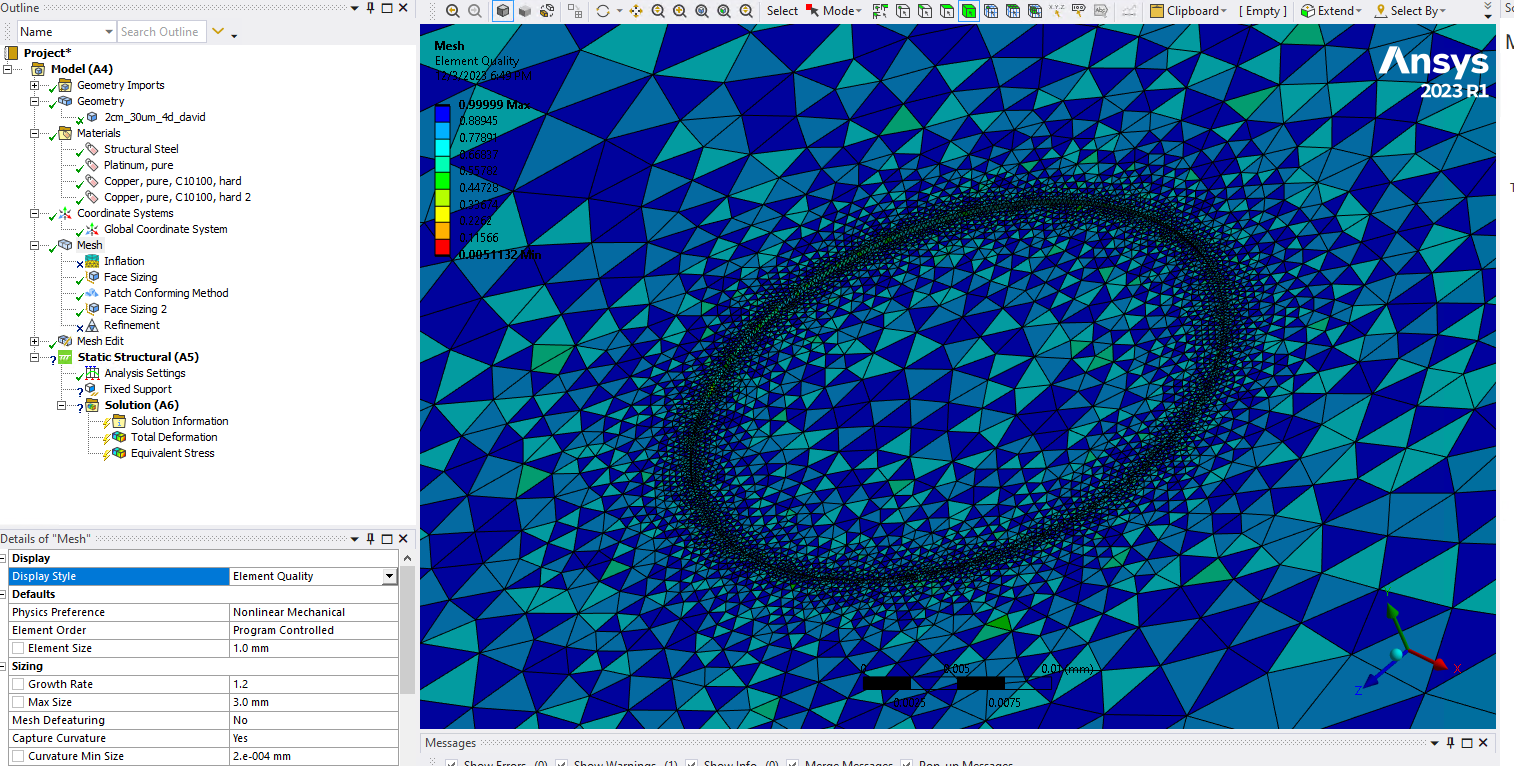

SubscriberI'm trying to create a high quality, uniform mesh across the volume of this sample. The sample is a copper foil (25 um thickness) with 45, 300 nm deep recesses in them. I've been able to optimize the mesh around the holes, but i'm experiencing a lot of issues with elements further away.. Should I split it up into different bodies,

or what?

or what? -

December 4, 2023 at 12:20 pm

Lydia

Ansys EmployeeHi Wyatt,

There are many approaches you can follow depending on your endgoal.

If you don't mind the meshing method. You could try local meshing sizings on edges and see what Size gives you the result you want. Splitting the bodies could help define more local sizing areas and therefore more controlled meshing.

If you would like to use almost exclusivelly hex elements, then the Thin Sweep method could be used for your geometry. You can have a look at this documentation link to see how it works https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v232/en/wb_msh/msh_specialized_thin_model_sweep.html?q=thin%20sweep

-

December 4, 2023 at 6:40 pm

jwyatteckstrom

SubscriberHi Lydia,

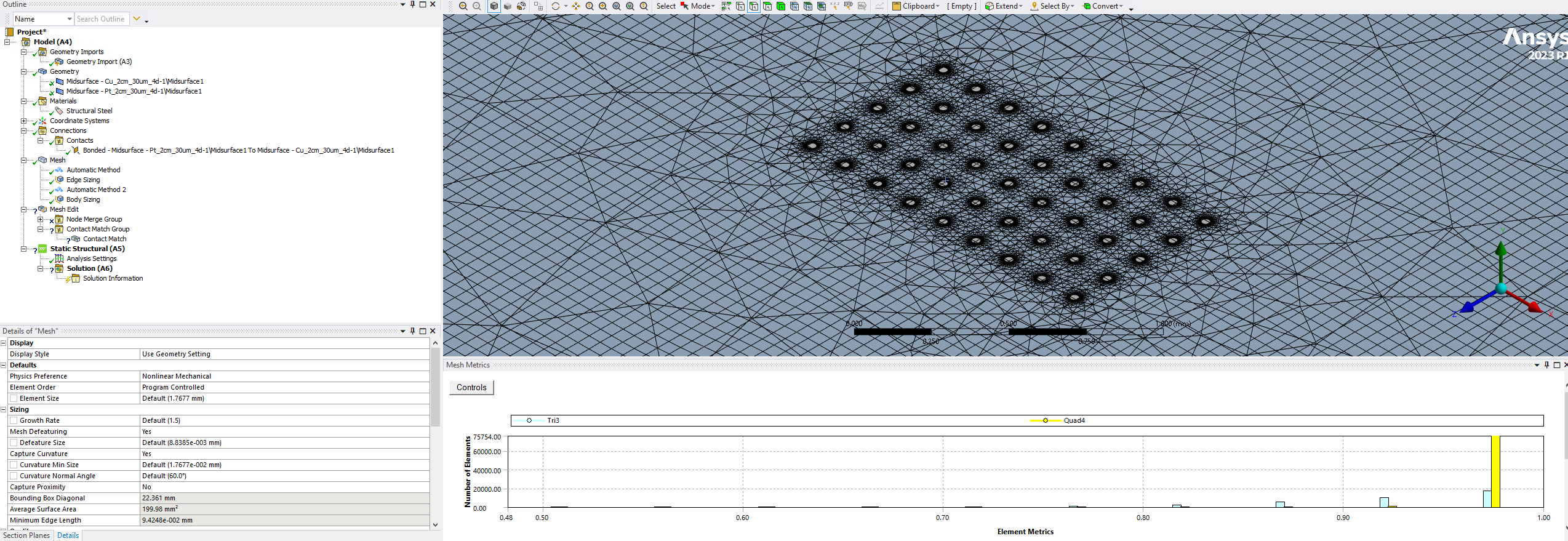

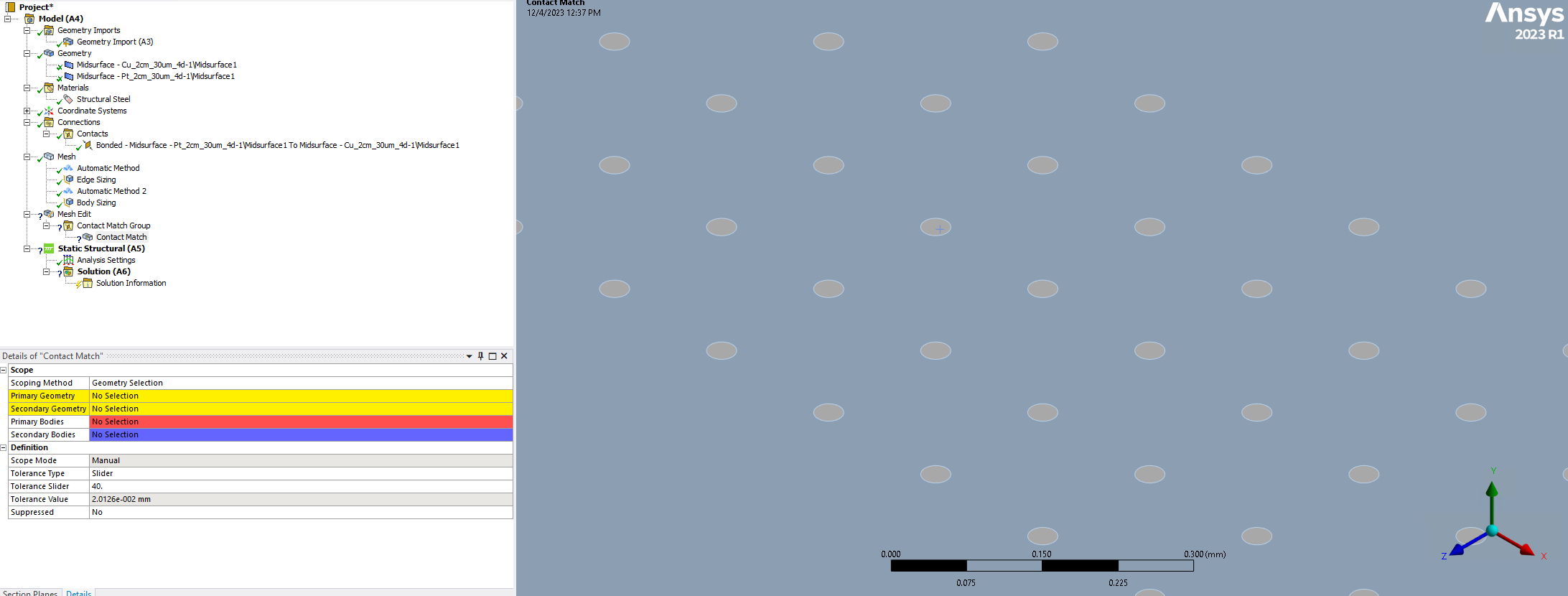

I couldn’t sweep it at all, so I decided to split the body into a 300 nm sheet (contains the holes) and a 25 um sheet (substrate to which the 300 nm sheet is bonded to), then extract the midsurfaces for a shell mesh. The quality of my mesh greatly improved, but i’m experiencing another issue: I can’t contact match the nodes at all. I’ve bonded the midsurfaces, but when I try contact matching, I’m not able to select the faces of interest. Here are a couple photos describing my issue.

-

- The topic ‘Issues with meshing thin geometry!’ is closed to new replies.

-

3407

-

1057

-

1051

-

896

-

887

© 2025 Copyright ANSYS, Inc. All rights reserved.