TAGGED: -LS-DYNA-run-time

-

-

May 19, 2025 at 9:10 am

giuseppe.iacolino

SubscriberDear all,

I’m running an explicit LS-DYNA drop-weight impact on a PLA BCC lattice.

To save time I model only ¼ of both the specimen and the impactor (mass scaled accordingly).

Runtime dropped from 14 h to 3 h, and deformation-vs-time and energy-vs-time curves match well between the ¼- and full-model runs.Problem: the reaction force from the ¼ model should scale by 4, but it only needs a factor ≈2 to match the full model—clearly unphysical. All other settings (material, mesh, BCs, outputs) are identical; only the geometry is quartered.

Has anyone seen this mismatch before or can suggest what I’m missing?

Thanks in advance,

Giuseppe

-

May 20, 2025 at 3:21 pm

Armin

Ansys EmployeeHi Giuseppe,

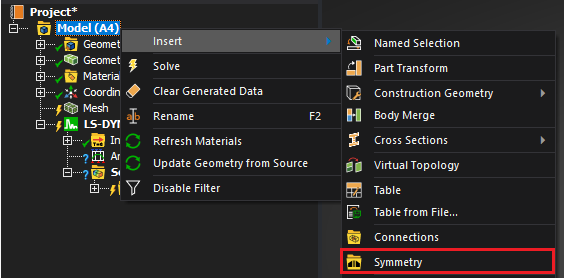

Have you applied the appropriate symmetry boundary conditions to accurately represent the response of the full model? If you’re using Workbench LS-DYNA to set up the model, you can apply symmetry boundary conditions by right-clicking on the Model branch and inserting “Symmetry.”

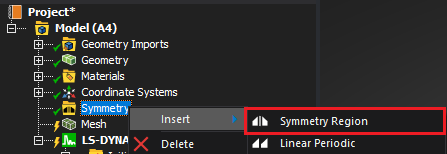

Next, insert a Symmetry Region as shown in the screenshot below, and choose the symmetry plane and symmetry normal. -

May 20, 2025 at 3:25 pm

giuseppe.iacolino

SubscriberHi Armin,

thank you for your kind response.

Yes, the 1/4 model is already implemented with simmetry regions. However, the problem persists.

Popup was blocked-

May 20, 2025 at 3:41 pm

Armin

Ansys EmployeeThanks for the verification. A couple of points to consider:

You mentioned mass scaling. Did you employ mass scaling to control (reduce) the computational time, or to account for the mass lost due to the symmetry application? If it is due to symmetry, you should avoid making any changes to the model, including mass scaling, except for adding the symmetry boundary conditions discussed earlier. If mass scaling is used to reduce the run time, you should compare your 1/4 model with a full model that also uses mass scaling.

I assume the impactor is rigid and the deformation of interest is for the specimen. If this is correct, consider running a case where you apply symmetry only to the specimen, while using the full geometry for the impactor. I expect that using symmetry for the impactor may not significantly reduce the simulation time.

-

-

May 21, 2025 at 7:53 am

giuseppe.iacolino

SubscriberDear Armin,

thank you for your message, and sorry for the misunderstanding. When I said "mass scaled," I meant that I considered only 1/4 of the impactor mass. Therefore, the impactor in the quarter model has a mass of 0.5 kg, while the full impactor weighs 2 kg.

Yes, the impactor is modeled as a rigid body.

Also, I have already tested the configuration with the full geometry for the impactor (without symmetry), but the issue still persists.

-

May 21, 2025 at 1:28 pm

Armin

Ansys EmployeeHi Giuseppe,

Thank you for clarifying this. I think it might be difficult to resolve this without looking at the model in more details. If you're a commercial customer, you can receive support via https://customer.ansys.com/

My other recommendation is to double-check the contact definition between the impactor and specimen, making sure contact pairs are used (instead of Body Interactions that can sometimes complicate interpretation of reaction forces).

-

-

May 22, 2025 at 8:00 am

giuseppe.iacolino

SubscriberDear Armin,

I found an explanation for the problem, which I would like to share below. I would appreciate your feedback.

The discrepancy in impact force between the full and quarter models arises from the local nature of contact forces in LS-DYNA. In the reduced model, only a fraction of the contact area is present, so the number of nodes contributing to the force calculation is limited. Since LS-DYNA sums contact pressures over the actual mesh segments involved, the resulting force is only partial and does not scale linearly. Physically, this is because pressure is not uniformly distributed across the surface, especially during the initial phase of impact when stress waves and local deformations occur asymmetrically. Therefore, multiplying the force by four does not yield a reliable estimate.

Additionally, if

CONTACT_AUTOMATIC_SINGLE_SURFACEis used, LS-DYNA does not output contact force data in theRCFORCfile due to the absence of a defined master surface. This is a known behavior. To accurately capture the impact force, aCONTACT_FORCE_TRANSDUCER_PENALTYshould be implemented. This transducer acts as a virtual sensor that integrates the force exchanged between parts, regardless of contact type. The observed force difference is thus not due to an error in symmetry, which is correctly applied, but to the way contact force is computed and extracted.

-

- You must be logged in to reply to this topic.

-

4512

-

1494

-

1386

-

1209

-

1021

© 2025 Copyright ANSYS, Inc. All rights reserved.