-

-

May 4, 2023 at 4:44 pm

Ali Bachar

SubscriberSo Im running a simulation on a wing with wash out, when loading the journal file and checking the boundary conditions, inlet and outlet are not set as per the journal file. However, when I directly copy the journal file into the fluent console (Ctrl + C/V) then enter, the boundaries are set. leading me to believe it is not an error with the code line itself, as it works in the console.

Why does it not registered from the journal file?

; READING MESH FILE

; Read mesh file (change the name according to your case)

/rc w02-559976.msh

; ENERGY MODEL

; Enable energy model and viscous heating

/define/models/energy y n n n y

; TURBULENCE MODEL

; Enable kw-SST turbulence model

/define/models/viscous/kw-sst y

; MATERIALS PROPERTIES

; Define air properties

/define/materials/change-create/air/air y incompressible-ideal-gas n n n n n n

; CELL ZONE CONDITIONS

; Set operating pressure to 86884 Pa

/define/operating-conditions/operating-pressure 86884.9682 q q

; BOUNDARY CONDITIONS

; Set temperature to 275.65K for pressure outlets

/define/boundary-conditions/set/pressure-outlet/farfield outlet () t0 n 275.65 q q q

; Set the temperature to 275.65K, the velocity to 113 m/s and the corresponding angles of attack in the velocity inlet

; WARNING: be careful to the axis of the model mesh and change the velocity components (x,y,z) accordingly

/define/boundary-conditions/velocity-inlet/inlet y y n 113.17 n 0 y n 0.99993 n 0.01220 n 0 n 275.65 n n y 5 10

; MONITORS

; Remove the residuals plot

/solve/monitors/residual/plot n q

; Set convergence criteria to 1e-03

/solve/monitors/residual/convergence-criteria 1e-03 1e-03 1e-03 1e-03 1e-03 1e-03 1e-03

; CALCULATIONS

; Run simulations for each speed and write the data file

; Adapt the number of iterations and the name of the written data file to your case

/solve/init/init

/solve/iter/500but if i copy this line and hit enter it accepts it>

/define/boundary-conditions/velocity-inlet/inlet y y n 113.17 n 0 y n 0.99993 n 0.01220 n 0 n 275.65 n n y 5 10

-

May 4, 2023 at 6:50 pm

Federico

Ansys EmployeeHello Ali,

I do not see any problem with your journal commands. I suggest you inspect your transcript file .trn for this session to check that there were no errors.

-

May 4, 2023 at 7:08 pm

Ali Bachar

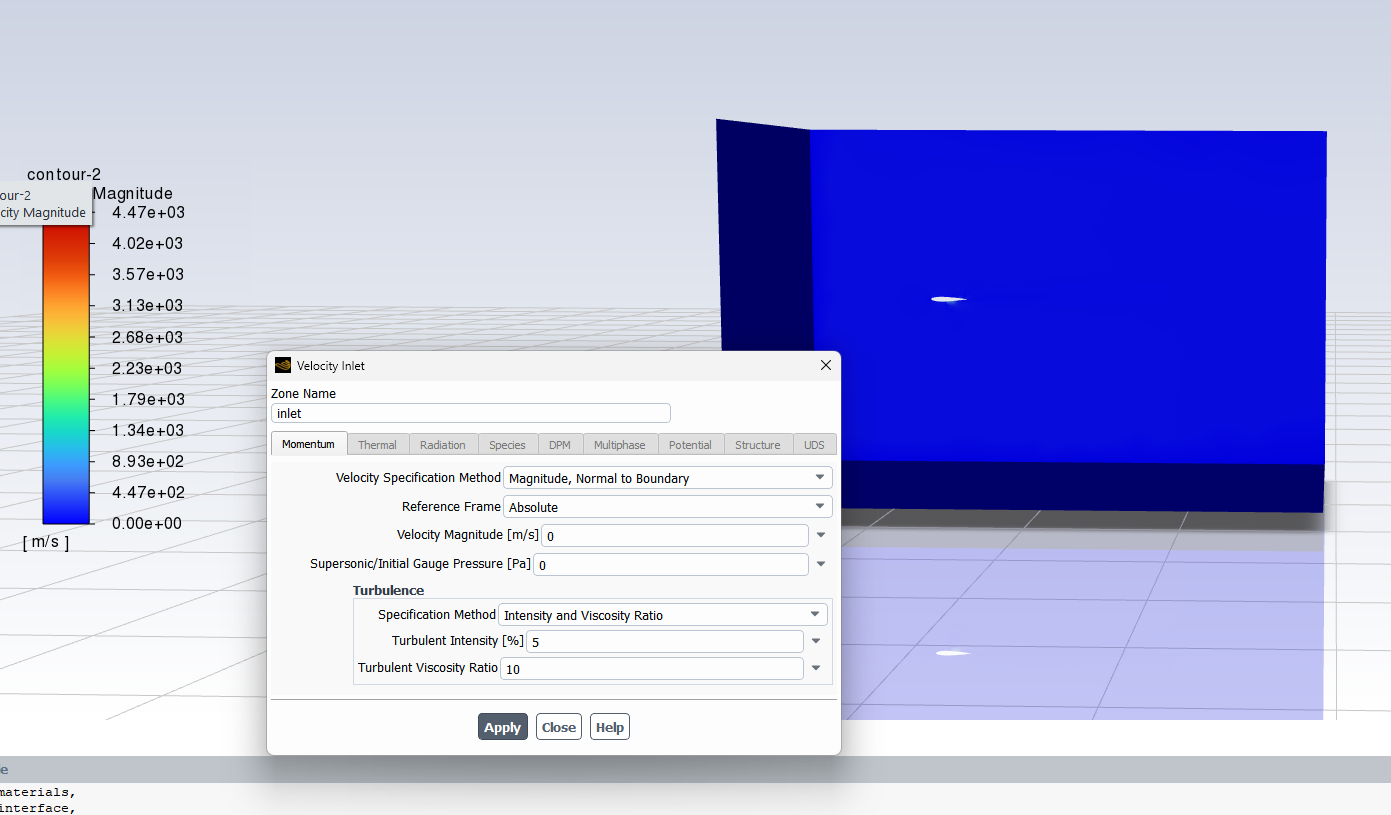

Subscriberin the trm, it seems to have executed fine, showing {inlet} after the command is run. however when plotting a velocity magnitude contour, after loading the journal file, produces a different result then when loading it in the console. it also shows 0 when you click boundary conditions - inlet after loading in the journal

-

-

May 4, 2023 at 7:10 pm

Federico

Ansys EmployeeDo you save the .cas and .dat files after running the journal?

-

May 4, 2023 at 7:12 pm

Ali Bachar

SubscriberI do, I am running it on a HPC, so i extract the .cas and .dat when the job execution finishes

-

-

May 5, 2023 at 8:52 am

Rob

Forum ModeratorWhat does the velocity GUI panel look like before & after running the journal line? It's always wise testing journals on smaller models to check the syntax. Additionally, the TUI string will vary depending on what models are set, and what options are used; they can also change when run a second time as "something" has been set that requires an extra y/n in the command. It's one of the reasons PyFluent is being developed as that should mean you can interact with specific values only without needing to worry about the rest of the boundary settings.

-

May 5, 2023 at 10:17 am

Ali Bachar

SubscriberSo the boundary conditions for inlet are set to the default values 0 magnitude 0 XYZ components etc

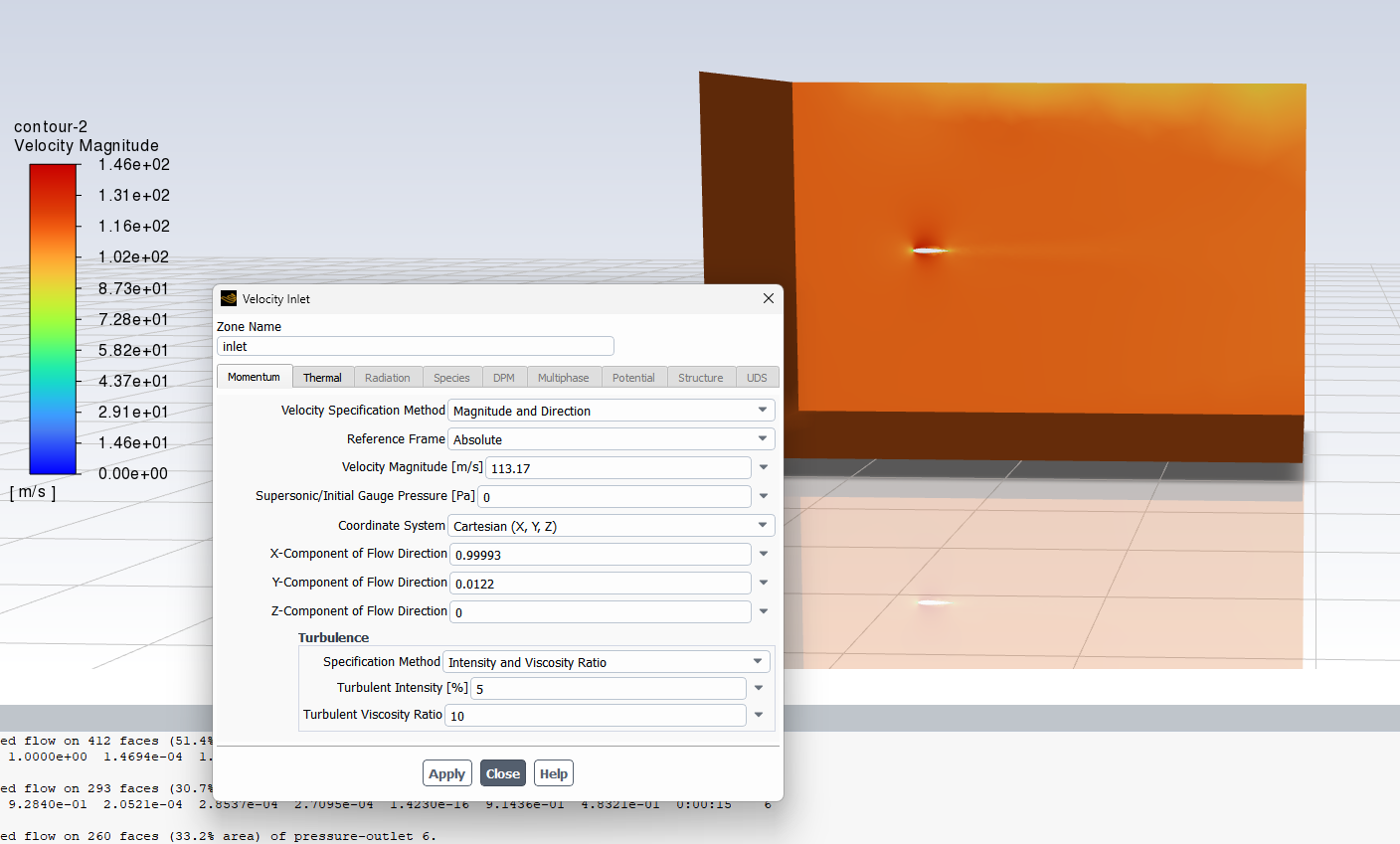

the journal file are run on both first time run! So I'll open fluent on the local machine. Copy/paste the journal file into to TUI, everything works, boundary conditions set. (Confirmed by velocity magnitude contour) and the BC panel will say magnitude 113 x component 0.99993 y component 0.0122 z component 0, and have the thermal set to 275

However, on the HPC if I load a submission file with my journal file (the exact same one I used before) and run it. The resulting .dat file will show that the boundary conditions for inlet/outlet are set at their defaults (this confirmed by looking at the velocity contour and seeing a region of 0ms at the inlet.

at first I thought they're musr be a rogue character or something, so I opened fluent locally and recorded a journal file with Writw -> Start Journal

and recorded what I typed into the TUI, and repeated the test with that new journal file, again same issue. When run off the journal file BC not set. When copied/paste boundaries set.

-

-

May 5, 2023 at 11:09 am

Rob

Forum ModeratorWhat does the transcript return when you run the journal? Try

/define/boundary-conditions/velocity-inlet/inlet () y y n 113.17 n 0 y n 0.99993 n 0.01220 n 0 n 275.65 n n y 5 10-

May 5, 2023 at 11:37 am

Ali Bachar

SubscriberSo when using 22.1 on the HPC with the above journal file (with the insertion of the ‘()’, this is the output, it seems as if everything executes, but the values say otherwise with the insertion of the brackets I get an even worse output!!

This is with () running on HPC ^

This is original journal file running on HPC ^

This is the expected results, which occurs when you Ctrl + A, Ctrl + C, Ctrl + V the exact journal file into the TUI locally ^

Auto-Transcript Start Time: 12:21:48, 05 May 2023

Current Directory: “/scratch/s381963″

/apps/software/ANSYS/2022R1/v221/fluent/fluent22.1.0/bin/fluent -r22.1.0 3ddp -pinfiniband -host -t64 -mpi=intel -cnf=/var/spool/pbs/aux/243792.crescentpbs -path/apps/software/ANSYS/2022R1/v221/fluent -ssh -cx ccn011.cluster:44585:34804

Starting /apps/software/ANSYS/2022R1/v221/fluent/fluent22.1.0/lnamd64/3ddp_host/fluent.22.1.0 host -cx ccn011.cluster:44585:34804 “(list (rpsetvar (QUOTE parallel/function) “fluent 3ddp -flux -node -r22.1.0 -t64 -pinfiniband -mpi=intel -cnf=/var/spool/pbs/aux/243792.crescentpbs -ssh”) (rpsetvar (QUOTE parallel/rhost) “”) (rpsetvar (QUOTE parallel/ruser) “”) (rpsetvar (QUOTE parallel/nprocs_string) “64”) (rpsetvar (QUOTE parallel/auto-spawn?) #t) (rpsetvar (QUOTE parallel/trace-level) 0) (rpsetvar (QUOTE parallel/remote-shell) 1) (rpsetvar (QUOTE parallel/path) “/apps/software/ANSYS/2022R1/v221/fluent”) (rpsetvar (QUOTE parallel/hostsfile) “/var/spool/pbs/aux/243792.crescentpbs”) (rpsetvar (QUOTE gpuapp/devices) “”))”

Welcome to ANSYS Fluent 2022 R1

Copyright 1987-2022 ANSYS, Inc. All Rights Reserved.

Unauthorized use, distribution or duplication is prohibited.

This product is subject to U.S. laws governing export and re-export.

For full Legal Notice, see documentation.

Build Time: Nov 29 2021 12:13:18 EST Build Id: 10213

Connected License Server List: 1055@cclic-2

————————————————————–

This is an academic version of ANSYS FLUENT. Usage of this product

license is limited to the terms and conditions specified in your ANSYS

license form, additional terms section.

————————————————————–

Host spawning Node 0 on machine “ccn011.cluster” (unix).

/apps/software/ANSYS/2022R1/v221/fluent/fluent22.1.0/bin/fluent -r22.1.0 3ddp -flux -node -t64 -pinfiniband -mpi=intel -cnf=/var/spool/pbs/aux/243792.crescentpbs -ssh -mport 10.0.1.11:10.0.1.11:37950:0

Starting /apps/software/ANSYS/2022R1/v221/fluent/fluent22.1.0/multiport/mpi/lnamd64/intel/bin/mpirun -f /tmp/fluent-appfile.s381963.80608 –rsh=ssh -genv I_MPI_FABRICS shm:dapl -genv I_MPI_DAPL_UD enable -genv I_MPI_FALLBACK_DEVICE disable -genv FLUENT_ARCH lnamd64 -genv I_MPI_DEBUG 0 -genv I_MPI_ADJUST_REDUCE 2 -genv I_MPI_ADJUST_ALLREDUCE 2 -genv I_MPI_ADJUST_BCAST 8 -genv I_MPI_ADJUST_BARRIER 2 -genv I_MPI_ADJUST_ALLGATHER 2 -genv I_MPI_ADJUST_GATHER 2 -genv I_MPI_ADJUST_ALLTOALL 1 -genv I_MPI_ADJUST_SCATTER 2 -genv I_MPI_ADJUST_SCATTERV 2 -genv I_MPI_ADJUST_ALLGATHERV 2 -genv I_MPI_ADJUST_GATHERV 2 -genv I_MPI_PLATFORM auto -genv I_MPI_DAPL_SCALABLE_PROGRESS 1 -genv PYTHONHOME /apps/software/ANSYS/2022R1/v221/fluent/fluent22.1.0/../../commonfiles/CPython/3_7/linx64/Release/python -genv FLUENT_PROD_DIR /apps/software/ANSYS/2022R1/v221/fluent/fluent22.1.0 -genv FLUENT_AFFINITY 0 -genv I_MPI_PIN enable -genv KMP_AFFINITY disabled -genv LD_PRELOAD /apps/software/ANSYS/2022R1/v221/fluent/fluent22.1.0/multiport/mpi/lnamd64/intel/lib/libstrtok.so -genv TMI_CONFIG /apps/software/ANSYS/2022R1/v221/fluent/fluent22.1.0/multiport/mpi/lnamd64/intel/etc/tmi.conf -machinefile /tmp/fluent-appfile.s381963.80608 -np 64 /apps/software/ANSYS/2022R1/v221/fluent/fluent22.1.0/lnamd64/3ddp_node/fluent_mpi.22.1.0 node -mpiw intel -pic infiniband -mport 10.0.1.11:10.0.1.11:37950:0

————————————————————————————

ID Hostname Core O.S. PID Vendor

————————————————————————————

n48-63 ccn014.cluster 16/16 Linux-64 39557-39572 Intel(R) Xeon(R) E5-2660 0

n32-47 ccn012.cluster 16/16 Linux-64 115260-115275 Intel(R) Xeon(R) E5-2660 0

n16-31 ccn013.cluster 16/16 Linux-64 89482-89497 Intel(R) Xeon(R) E5-2660 0

n0-15 ccn011.cluster 16/16 Linux-64 82260-82275 Intel(R) Xeon(R) E5-2660 0

host ccn011.cluster Linux-64 80412 Intel(R) Xeon(R) E5-2660 0

MPI Option Selected: intel

Selected system interconnect: InfiniBand

————————————————————————————

Cleanup script file is /scratch/s381963/cleanup-fluent-ccn011.cluster-80412.sh

Posting ANSYS Product Improvement Program startup data

Done.

> /file/set-tui-version “22.1”

> /file/read-case “w02-559976.msh”

Reading “w02-559976.msh”…

Buffering for file scan…

103882 nodes, binary.

6722 nodes, binary.

1133582 mixed interior faces, zone 1, binary.

537 triangular velocity-inlet faces, zone 5, binary.

713 triangular pressure-outlet faces, zone 6, binary.

3878 mixed symmetry faces, zone 7, binary.

8097 triangular wall faces, zone 8, binary.

559976 mixed cells, zone 2, binary.

Building…

mesh

auto partitioning mesh by Metis (fast),

distributing mesh

parts…………………………………………..,

faces…………………………………………..,

nodes…………………………………………..,

cells…………………………………………..,

inter-node communication reduction using architecture-aware remapping: 59%

bandwidth reduction using Reverse Cuthill-McKee: 8892/462 = 19.2468

materials,

interface,

domains,

zones,

wall

symmetry

outlet

inlet

fluiddomain

interior-fluiddomain

parallel,

Done.

> /define/models/energy? y n n n y

> /define/models/viscous/kw-sst? y

> /define/materials/change-create air air air is a fluid

y

Density

incompressible-ideal-gas no data required.

n n n n n n

> /define/operating-conditions/operating-pressure 86884.9682

> /define/boundary-conditions/set/pressure-outlet outlet () t0 n 275.65 quit

> /define/boundary-conditions/velocity-inlet (inlet)

inlet ()Please answer y[es] or n[o].

y y n 113.17 n 0 y n 0.99993 n 0.0122 n 0 n 275.65 n n y 5 10

> /solve/monitors/residual/plot? n

> /solve/monitors/residual/convergence-criteria 0.001 0.001 0.001 0.001 0.001 0.001 0.001

> /solve/initialize/compute-defaults/velocity-inlet (inlet)

inlet

> /solve/initialize/initialize-flow

> /solve/iterate 10

iter continuity x-velocity y-velocity z-velocity energy k omega time/iter

1 1.0000e+00 2.1661e-08 2.6245e-09 8.4171e-10 9.4372e-17 9.8517e-01 4.9594e-01 0:00:04 9

Reversed flow on 92 faces (12.8% area) of pressure-outlet 6.

Stabilizing pressure coupled to enhance linear solver robustness.

2 1.0000e+00 7.8196e-07 6.0298e-07 1.6989e-05 1.3736e-16 9.7570e-01 4.9342e-01 0:00:06 8

Reversed flow on 402 faces (50.5% area) of pressure-outlet 6.

3 1.0000e+00 3.6056e-05 2.2458e-04 8.3966e-05 1.4572e-16 9.5851e-01 4.8956e-01 0:00:04 7

Reversed flow on 287 faces (30.1% area) of pressure-outlet 6.

4 1.0000e+00 2.8666e-05 5.3652e-05 3.8766e-05 1.5503e-16 9.2614e-01 4.8324e-01 0:00:03 6

Reversed flow on 265 faces (33.8% area) of pressure-outlet 6.

5 6.3999e-01 6.5669e-05 2.5260e-04 7.7242e-05 2.1236e-16 1.1216e+00 4.7279e-01 0:00:03 5

Reversed flow on 250 faces (31.3% area) of pressure-outlet 6.

6 7.8490e-01 4.5025e-05 7.4854e-05 4.8660e-05 1.1593e-15 8.3821e-01 4.5557e-01 0:00:02 4

Reversed flow on 216 faces (25.3% area) of pressure-outlet 6.

7 6.3548e-01 4.1996e-05 1.1698e-04 5.1480e-05 2.3377e-15 7.7233e-01 4.2520e-01 0:00:01 3

Reversed flow on 244 faces (30.3% area) of pressure-outlet 6.

8 6.7845e-01 3.9463e-05 5.0019e-05 3.5548e-05 1.1140e-14 1.3640e+00 3.8517e-01 0:00:01 2

Reversed flow on 219 faces (26.7% area) of pressure-outlet 6.

9 5.4719e-01 3.5438e-05 6.0341e-05 3.5188e-05 6.7081e-13 5.6467e-01 3.1867e-01 0:00:00 1

Reversed flow on 212 faces (26.9% area) of pressure-outlet 6.

10 4.9685e-01 3.1213e-05 3.2773e-05 2.6411e-05 6.1261e-13 4.8691e-01 2.5416e-01 0:00:00 0

> /file/write-data “testing.dat.h5″Fast-loading “/apps/software/ANSYS/2022R1/v221/fluent/fluent22.1.0/addons/afd/lib/hdfio.bin”

Done.

Writing to ccn011.cluster:”/scratch/s381963/testing.dat.h5” in NODE0 mode and compression level 1 …

Writing results.

Done.

> /exit

Posting ANSYS Product Improvement Program performance data

Done.

ok Auto-Transcript Stop Time: 12:27:15, 05 May 2023

Total Transcript Time: 5 Minute 26 Second.

-

-

May 5, 2023 at 12:27 pm

Rob

Forum ModeratorI think you have other problems further up the journal. Are you using Read>Journal when checking the model locally?

> /define/materials/change-create air air air is a fluid

y

Density

incompressible-ideal-gas no data required.

n n n n n n

> /define/operating-conditions/operating-pressure 86884.9682

> /define/boundary-conditions/set/pressure-outlet outlet () t0 n 275.65 quit-

May 5, 2023 at 12:48 pm

Ali Bachar

SubscriberNo, i am entering line by line, using Read>Journal I believe causes the same error.

I cannot see what is wrong with that? that is the correct number of values

/define> materials

/define/materials>

change-create data-base/ list-properties

copy delete

copy-by-formula list-materials

/define/materials> change-create

material-name> air

material name [air] air

air is a fluid

change Density? [no] y

Density

methods: (constant ideal-gas incompressible-ideal-gas rgp-table real-gas-soave-redlich-kwong real-gas-peng-robinson real-gas-aungier-redlich-kwong real-gas-redlich-kwong boussinesq piecewise-linear piecewise-polynomial polynomial expression compressible-liquid user-defined)

new method [constant] incompressible-ideal-gas

no data required.

change Cp (Specific Heat)? [no] n

change Thermal Conductivity? [no] n

change Viscosity? [no] n

change Molecular Weight? [no] n

change Thermal Expansion Coefficient? [no] n

change Speed of Sound? [no] n

-

-

May 5, 2023 at 12:52 pm

Rob

Forum ModeratorIt's the "no data required" that isn't clear.

-

May 5, 2023 at 1:07 pm

Ali Bachar

SubscriberI think that is because when you select incompressible-ideal-gas the density variable greys out instead of when its set at constant asks me to insert a value, - hence no data required

-

-

- The topic ‘Inlet/Outlet Will not set when using a journal file’ is closed to new replies.

-

3402

-

1052

-

1051

-

896

-

877

© 2025 Copyright ANSYS, Inc. All rights reserved.