-

-

October 23, 2020 at 1:33 am

moranlouie

Subscriber-------------------------------------------------------------------------------------------------------------------------------------------------------------n iter continuity x-velocity y-velocity z-velocity energy k epsilon time/itern Stabilizing pressure coupled to enhance linear solver robustness.n 1 1.0000e+00 5.8836e-03 7.9742e-05 5.9378e-03 6.6224e-07 7.2615e-17 2.7938e-02 174:41:25 1999n Stabilizing pressure coupled to enhance linear solver robustness.nn turbulent viscosity limited to viscosity ratio of 1.000000e+05 in 2818 cells n 2 1.0000e+00 3.5837e-03 6.6482e-04 3.6084e-03 3.8815e-05 1.1343e-16 1.4673e-02 183:24:59 1998n Stabilizing pressure coupled to enhance linear solver robustness.n Stabilizing pressure coupled using GMRES to enhance linear solver robustness.nnExperiencing convergence difficulties - temporarily relaxing and trying again...nnExperiencing convergence difficulties - temporarily relaxing and trying again...nnExperiencing convergence difficulties - temporarily relaxing and trying again...nnExperiencing convergence difficulties - temporarily relaxing and trying again...n Stabilizing pressure coupled to enhance linear solver robustness.n Stabilizing pressure coupled using GMRES to enhance linear solver robustness.nnExperiencing convergence difficulties - temporarily relaxing and trying again...nnDivergence detected in AMG solver: pressure coupledn turbulent viscosity limited to viscosity ratio of 1.000000e+05 in 308 cells nnDivergence detected in AMG solver: pressure couplednDivergence detected in AMG solver: pressure couplednDivergence detected in AMG solver: pressure couplednError at host: floating point exceptionn-------------------------------------------------------------------------------------------------------------------------------------------------------------nnPlease and Thank youn -

October 23, 2020 at 2:33 am

Keyur Kanade

Ansys EmployeeYour solution is diverged. nPlease give more information and upload images. nFirst check your mesh using Domain - Mesh - Check. Mesh check should pass. If it fails then you will need to correct the mesh. The min orthogonal quality should be above 0.1. nMake sure your mesh is sufficiently refined to capture flow. nWhat is your application? What are boundary conditions used? What models you are using? Please upload some images. nAlso please search through forum for more resources. nRegards,nKeyurnGuidelines for Posting on Ansys Learning ForumnHow to access ANSYS help linksnn -

October 24, 2020 at 2:28 am

moranlouie

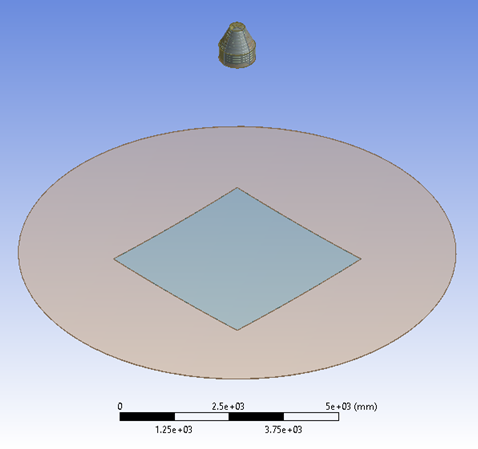

SubscriberGood morning, Keyur,nThis is the same problem I have been posting for a while now. I am simulating a concentrated solar powers generator, with a pressure-based, steady-state simulation; using the energy equation and a realizable, standard wall functions k-epsilon viscous model. I applied yours and Rob's suggestions from the previous question, and achieved a maximum skewness of 0.63881 and a minimum ortho quality of 0.36119, with a lot of trial and error. so the new geometry looks like this:n I suppressed the disk to simulate a simple heat-exchange phenomenon and root out problems in this aspect of the simulation; which should be simple, but I can't do for some reason. This is the receiver cavity:n

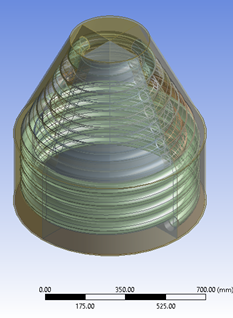

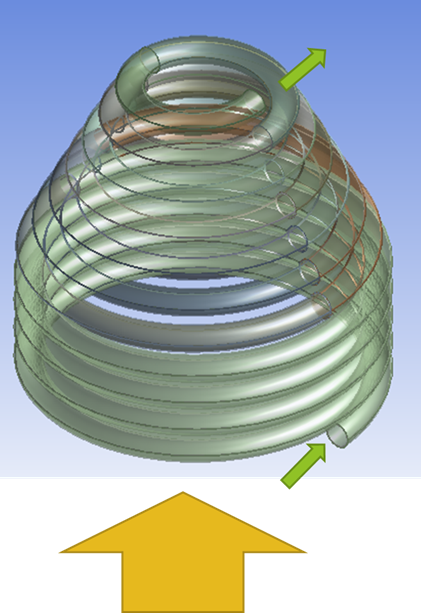

I suppressed the disk to simulate a simple heat-exchange phenomenon and root out problems in this aspect of the simulation; which should be simple, but I can't do for some reason. This is the receiver cavity:n The cavity is set to duratherm600 heat exchanger fluid. Tubes and Freon:n

The cavity is set to duratherm600 heat exchanger fluid. Tubes and Freon:n The fluid is set to R-12, while the tubes are set to copper. nThe inlet at the bottom is set to velocity-inlet, velocity magnitude: 0.4 m/s, total temperature: 298.15 K. I used a pressure outlet for the top tube, gauge pressure of 0 pascal, total backflow temperature of 301 K. The wall at the bottom of the cavity is set to heat flux, calcium carbonate material, heat flux of 5500 w/m^2, wall thickness of 0.002 m, and 0 heat generation rate; while the other walls are aluminum with no heat flux. The interfaces between cavity to copper tubes and copper tubes to Freon were set to coupled/mapped. Cavity to cavity, since the geometry has been chopped-up for the meshing, is set to matching. All the interfaces are flushed together after being chopped-up except these two parts of the cavity.n

The fluid is set to R-12, while the tubes are set to copper. nThe inlet at the bottom is set to velocity-inlet, velocity magnitude: 0.4 m/s, total temperature: 298.15 K. I used a pressure outlet for the top tube, gauge pressure of 0 pascal, total backflow temperature of 301 K. The wall at the bottom of the cavity is set to heat flux, calcium carbonate material, heat flux of 5500 w/m^2, wall thickness of 0.002 m, and 0 heat generation rate; while the other walls are aluminum with no heat flux. The interfaces between cavity to copper tubes and copper tubes to Freon were set to coupled/mapped. Cavity to cavity, since the geometry has been chopped-up for the meshing, is set to matching. All the interfaces are flushed together after being chopped-up except these two parts of the cavity.n nI used a piecewise linear and polynomial fluid properties of Duratherm 600 for the simulation, which I found was causing the early floating point exception. I used instead, constant properties, which are taken from the catalogue.n

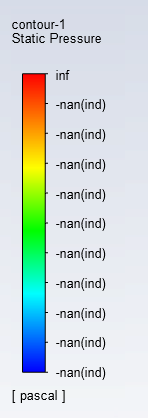

nI used a piecewise linear and polynomial fluid properties of Duratherm 600 for the simulation, which I found was causing the early floating point exception. I used instead, constant properties, which are taken from the catalogue.n Now I get 4 new errors and the solver limits turbulent viscosity. Here is iteration 212, I added the iteration line for better context:n--------------------------------------------------------------------------------------------------------------------------------------------------niter continuity x-velocity y-velocity z-velocity energy k epsilon time/iternturbulent viscosity limited to viscosity ratio of 1.000000e+05 in 3080715 cellsn212 1.2983e+40 4.5998e-02 8.1731e-02 1.8405e-01 3.9475e-10 3.0332e-02 1.0000e+00 73:56:53 1788n Stabilizing pressure coupled to enhance linear solver robustness.n Negative epsilon in 1250 cells after linear solve.n Stabilizing temperature to enhance linear solver robustness.n Stabilizing temperature using GMRES to enhance linear solver robustness.n--------------------------------------------------------------------------------------------------------------------------------------------------nI tried getting the static pressure gradient, and I'm not sure whether to laugh or cry:n

Now I get 4 new errors and the solver limits turbulent viscosity. Here is iteration 212, I added the iteration line for better context:n--------------------------------------------------------------------------------------------------------------------------------------------------niter continuity x-velocity y-velocity z-velocity energy k epsilon time/iternturbulent viscosity limited to viscosity ratio of 1.000000e+05 in 3080715 cellsn212 1.2983e+40 4.5998e-02 8.1731e-02 1.8405e-01 3.9475e-10 3.0332e-02 1.0000e+00 73:56:53 1788n Stabilizing pressure coupled to enhance linear solver robustness.n Negative epsilon in 1250 cells after linear solve.n Stabilizing temperature to enhance linear solver robustness.n Stabilizing temperature using GMRES to enhance linear solver robustness.n--------------------------------------------------------------------------------------------------------------------------------------------------nI tried getting the static pressure gradient, and I'm not sure whether to laugh or cry:n The first error I noticed in the first 2 iterations (simulation was incredibly slow, taking, maybe, 15 minutes to do one iteration). The turbulent viscosity was being limited since iteration 50, one of the four errors pop-up every now and then, and it ends at 212 like that. I've been posting regarding this problem for a while now. Thank you to you and Rob for your suggestions and advice. nnRight now, I noticed the copper tube walls were set to aluminum and set to heat flux, so I'm trying setting them to copper and using a w/ coupling setting, while all else are unchanged. Also, I was supposed set all the interfaces between similar domains to matching and I only noticed now that only the cavity was set to this.n

The first error I noticed in the first 2 iterations (simulation was incredibly slow, taking, maybe, 15 minutes to do one iteration). The turbulent viscosity was being limited since iteration 50, one of the four errors pop-up every now and then, and it ends at 212 like that. I've been posting regarding this problem for a while now. Thank you to you and Rob for your suggestions and advice. nnRight now, I noticed the copper tube walls were set to aluminum and set to heat flux, so I'm trying setting them to copper and using a w/ coupling setting, while all else are unchanged. Also, I was supposed set all the interfaces between similar domains to matching and I only noticed now that only the cavity was set to this.n

-

October 26, 2020 at 4:13 am

Keyur Kanade

Ansys EmployeeAre you using tetrahedron method for volume mesh? nWhy are you using interfaces? Can you create a conformal mesh? You need to use share topology option to get conformal mesh. nPlease upload image of cross section of your mesh. Do you have sufficient mesh density? I doubt that mesh resolution may not be good. You may need to refine mesh. Are you using student version which has 512K cells limitations? nCan you first please switch on energy equations and solve only for flow? If that succeeds then switch on energy equation with some dummy constant properties. Then go for polynomial. n -

October 26, 2020 at 8:48 am

moranlouie

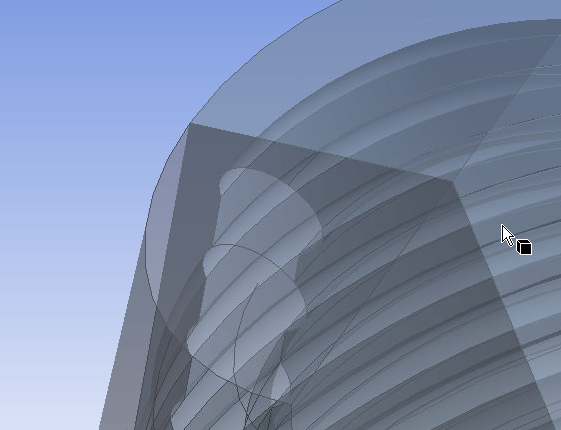

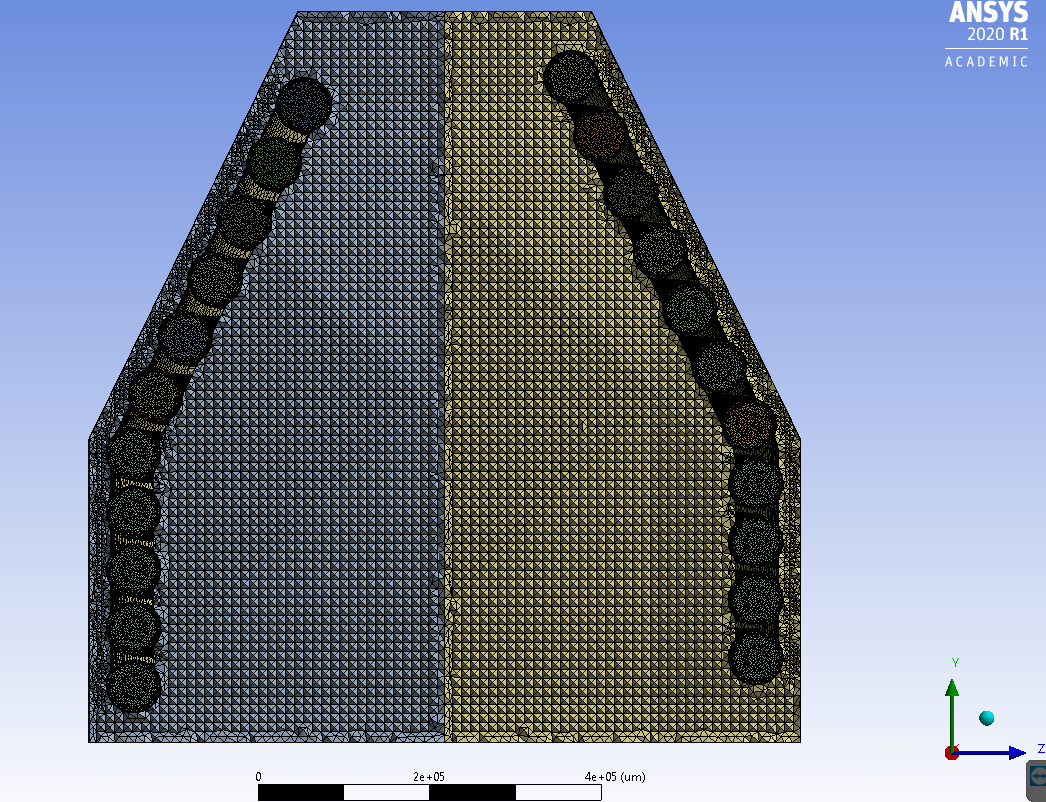

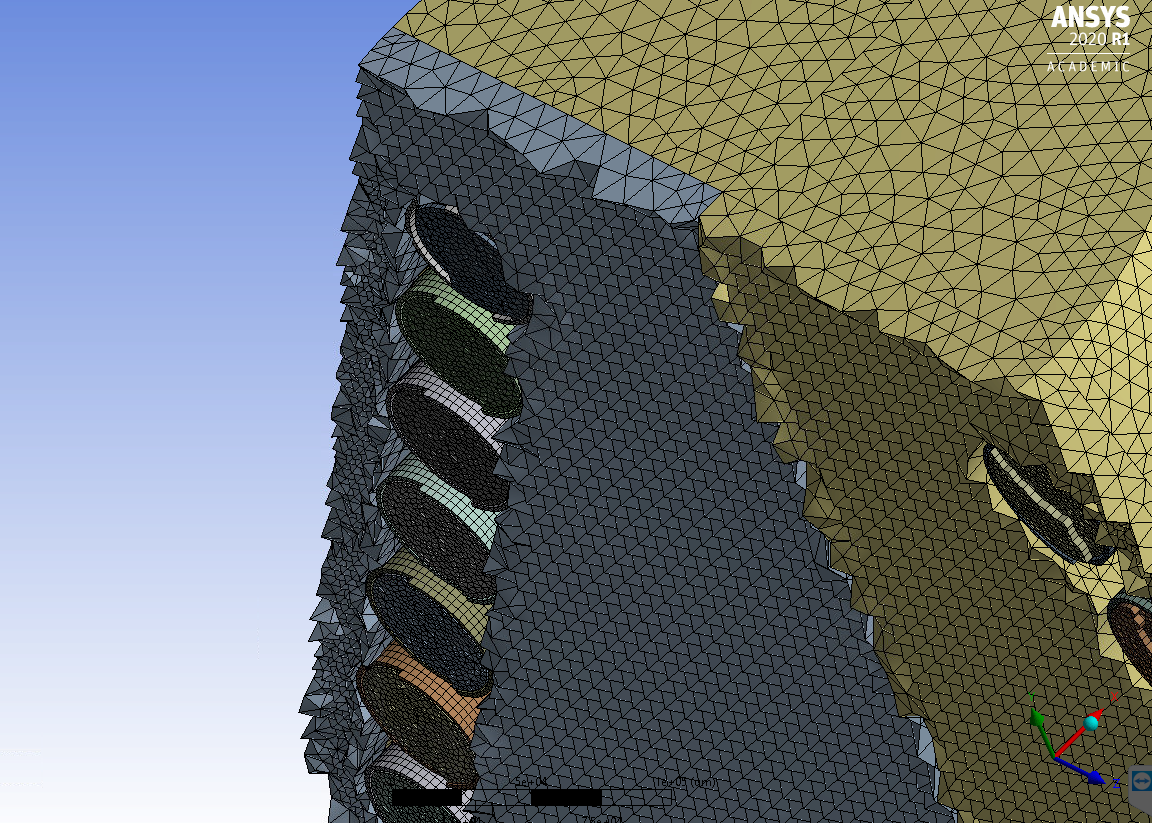

SubscriberI am using a tetrahedron for the cavity. The geometry was chopped-up so I could get better mesh quality so interfaces were used. I have not tried using a conformal mesh. Where can I find the share topology option?nHere is the cross-section of the mesh: Y-Z Orientation:n Details on Y-Z Orientation:n

Details on Y-Z Orientation:n Y-X Orientation:n

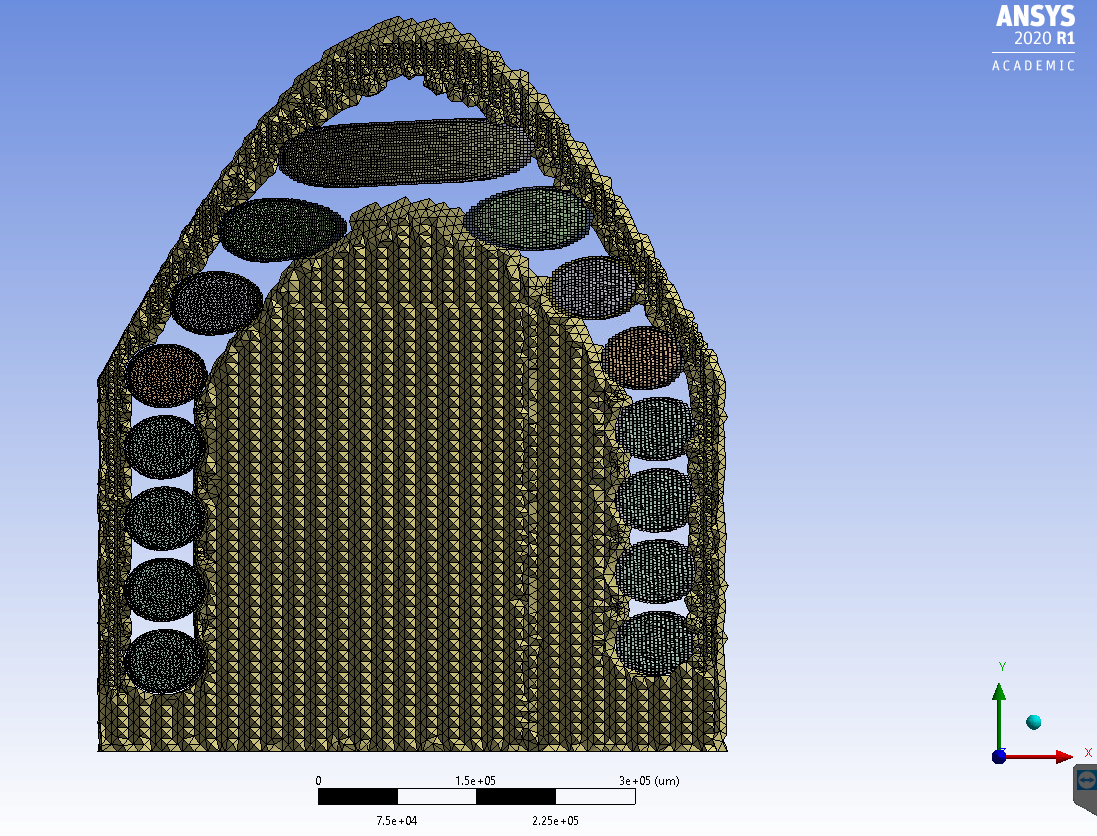

Y-X Orientation:n Details on Y-X:n

Details on Y-X:n I'm not sure how to asses if the mesh density is sufficient for the simulation. I am using a Research license. I cannot access my advisor's costumer number as of now, so I'm asking around at the educational forum.nI will try your suggestion with the energy equations. Than you!n

I'm not sure how to asses if the mesh density is sufficient for the simulation. I am using a Research license. I cannot access my advisor's costumer number as of now, so I'm asking around at the educational forum.nI will try your suggestion with the energy equations. Than you!n

-

October 26, 2020 at 10:04 am

Keyur Kanade

Ansys EmployeeYou are using patch independent tetrahedron. nHere is video on share topology nPlease see help manual for more details about these commands. nn

-

Viewing 5 reply threads

- The topic ‘I need help with this error:’ is closed to new replies.

Innovation Space

Trending discussions

Top Contributors

-

4893

-

1587

-

1386

-

1242

-

1021

Top Rated Tags

© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.