-

-

December 18, 2023 at 8:44 am

agambhir_be20

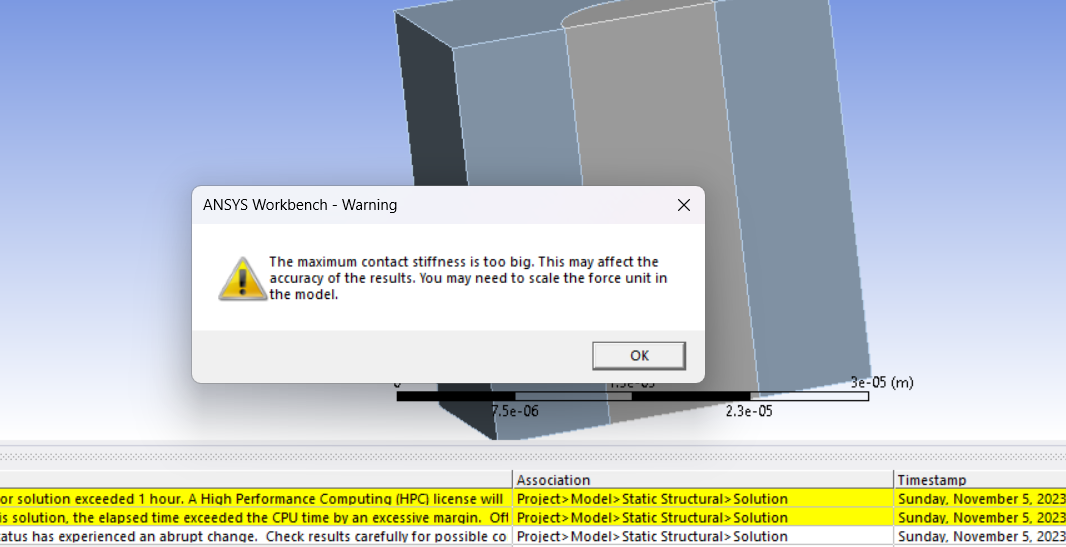

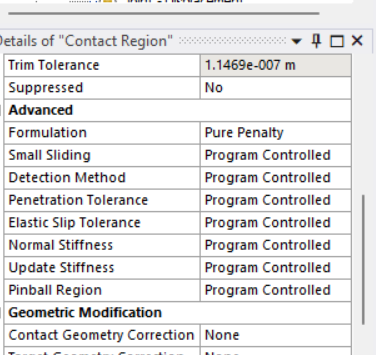

SubscriberI'm doing fiber push-out simulations and took the data from an experiment. I'm not able to match the results with the experimental findings as it says the contact stiffness is very high. However, the contact stiffness is program-controlled in my simulations, how can i change it?

I tried changing it to an absolute value but i get an error when i run the simulations with any random stiffness value.

-

December 20, 2023 at 10:40 am

Ashish Khemka

Forum ModeratorHi,

Please see if the following post helps: Maximum contact stiffness is too big (ansys.com)

Regards,

Ashish Khemka

-

December 20, 2023 at 11:03 am

mjmiddle

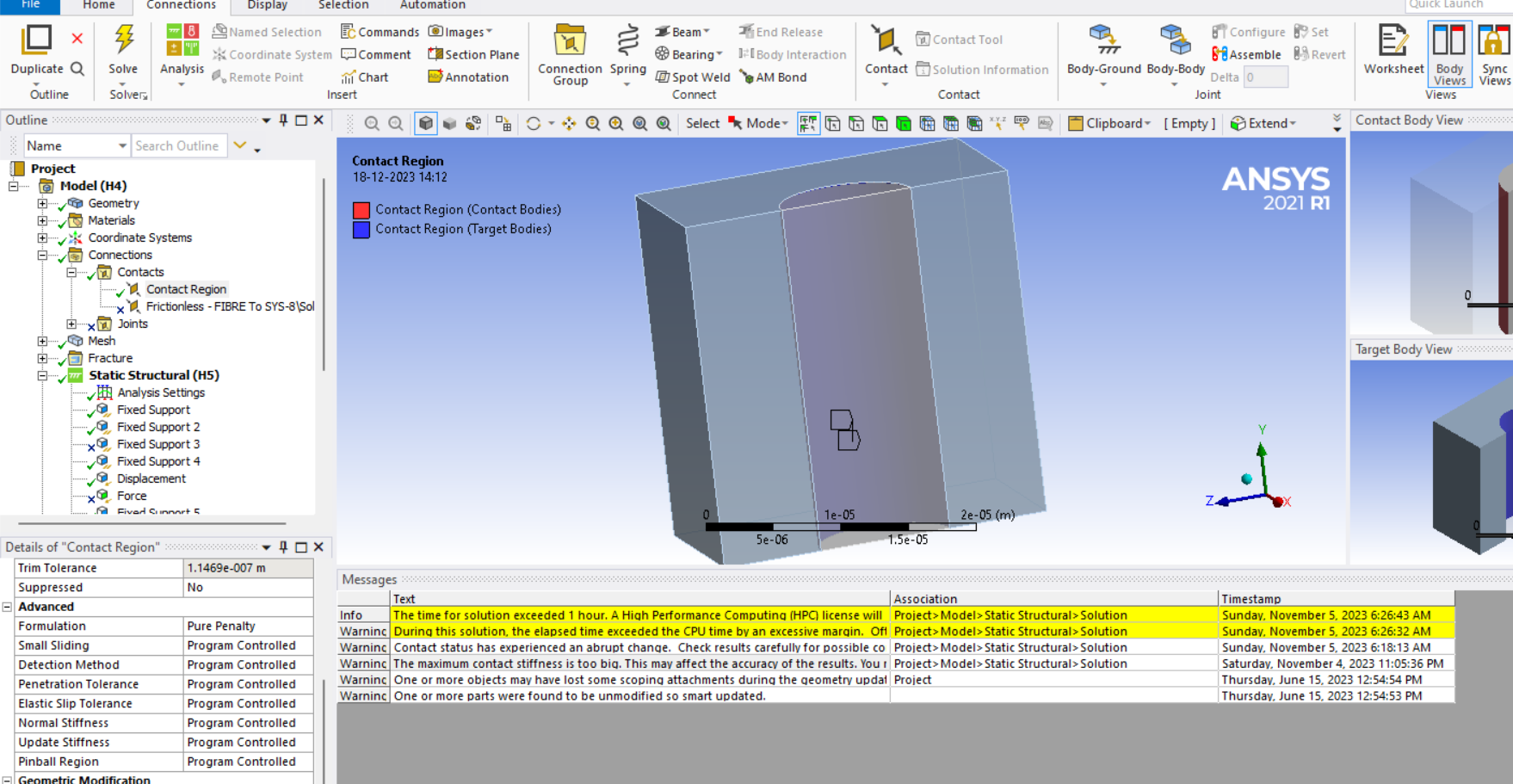

Ansys EmployeeThis warning message is stating that the magnitude of the contact stiffness is a very large number, probably orders of magnitude higher than other stiffness values in the stiffness matrix. Since very large numbers in the stiffness matrix can cause ill-conditioning when trying to solve the numerical system, this automated warning is recommending that you check your results to make sure they look ok, and that you consider changing the unit system to avoid very large magnitude numbers. Ill-conditioning can occur when you have a matrix that has very large and very small numbers on the diagonal, say 1e20 and 1e0, and when the code tries to use this stiffness matrix to solve the problem, the small numbers essentially get wiped out. This can cause convergence or accuracy issues.

However, this is just an automated warning. If your analysis seems to be converging successfully, this warning may not be serious. If you review your results and verify that they are accurate, you can ignore this warning.

To eliminate the error, the easiest thing to do is to use a different unit system. For example, consider a stress of 145 ksi. This same stress is 1e9 Pa (N/m^2), or 1 billion Pa. Using Pa units, you can easily see that you may end up with some very large number magnitudes, and if they get large enough, there is a chance for numerical problems during the solve, and thus the automated warning. This warning is not saying that your contact stiffness is incorrect, just that the magnitude is exceeding some internal magnitude that is considered a large number. However, if the analysis is running successfully, it is just a warning, you can just ignore.

If this is the warning you get, then it gives a recommendation of using a different unit system during solution, which is exactly what you should do. Using a smaller length unit system, such as changing from meter to millimeters, will make the contact stiffness a smaller number by 1E9. The contact stiffness has units with force/length^3, so smaller length values (mm->m) will increase the contact stiffness value. Note that using smaller force unit system (N->dyne) will make the contact stiffness larger. 1e5 dyne = 1 N. So changing unit system from m,kg,N to mm,kg,N decreases the contact stiffness by 1e9, whereas changing unit system from m,kg,N to cm,g,dyne only decreases the contact stiffness by 1E1 (decrease by 1E6 from m->cm with increase by 1E5 from N->dyne). Changing unit system from m,kg,N to um,kg,uN will decrease the contact stiffness by 1e12 (decrease by 1e18 from m->cm with increase by 1e6 from N->uN). The warning is triggered when the initial contact stiffness value is 1E17 or larger.

In the Solution Information, you can check the initial contact stiffness in sections like below:

*** NOTE *** CP = 0.375 TIME= 19:54:32

Symmetric Deformable- deformable contact pair identified by real

constant set 3 and contact element type 3 has been set up. The

companion pair has real constant set ID 4. Both pairs should have the

same behavior.

ANSYS will deactivate the current pair and keep its companion pair,

resulting in asymmetric contact.

Linear contact is defined

Contact algorithm: Augmented Lagrange method

Contact detection at: Gauss integration point

Contact stiffness factor FKN 10.000

The resulting initial contact stiffness 0.30000E+17 <------------------------------------

Default penetration tolerance factor FTOLN 0.10000

The resulting penetration tolerance 0.12000E-03

Default opening contact stiffness OPSF will be used.

Default tangent stiffness factor FKT 1.0000

Use constant contact stiffness

Default Max. friction stress TAUMAX 0.10000E+21

Average contact surface length 0.11931E-02

Average contact pair depth 0.12000E-02

Default pinball region factor PINB 0.25000

The resulting pinball region 0.30000E-03

Initial penetration/gap is excluded.

Bonded contact (always) is defined.-

December 30, 2023 at 7:24 pm

agambhir_be20

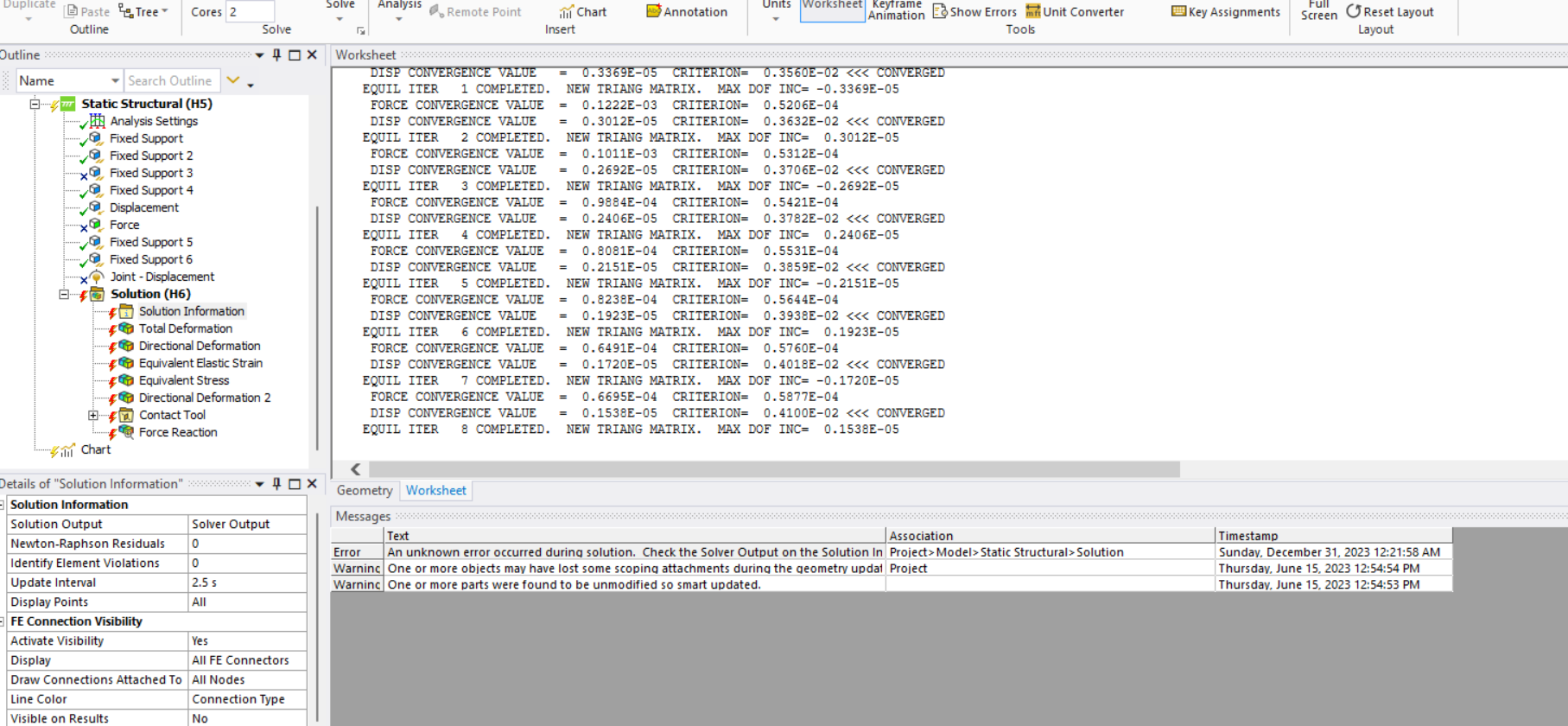

Subscriber

-

-

December 30, 2023 at 8:54 pm

mjmiddle

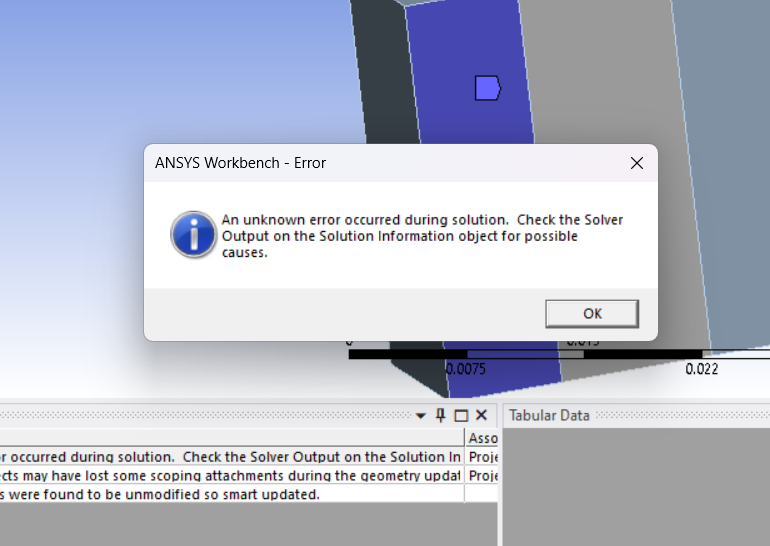

Ansys EmployeeAn abrupt end like that during an iteration with no message is normally a loss of license, or something killed or interrupted the process, like a machine reboot or a user manually killing your processes on a server machine or a 1-user machine where a remote login killed all processes of the current user when the login overrides the current login. Maybe Ansys run is from a served network and you lost network connection.

-

- The topic ‘How to change contact stiffness’ is closed to new replies.

-

4833

-

1587

-

1386

-

1242

-

1021

© 2026 Copyright ANSYS, Inc. All rights reserved.