-

-

December 31, 2024 at 1:39 am

josegegas

SubscriberHello. When one performs a transient simulation, joint force and torque must be distributed among the fem nodes belonging to the bearing face. I was wondering if user has any control over how this distribution takes place? I am trying to simulate a simple flexible pendulum but I do not get correct answers because Ansys seems to apply the joint force to the wrong face nodes using the default configurations at least.

Any help will be welcome. Thanks

-

December 31, 2024 at 2:37 pm

peteroznewman

SubscriberPlease reply with more details. What kind of joint? What kind of elements (solid, shell, beam)? What is the shape of the bearing face? What is the correct answer and where did that come from?

-

December 31, 2024 at 6:34 pm

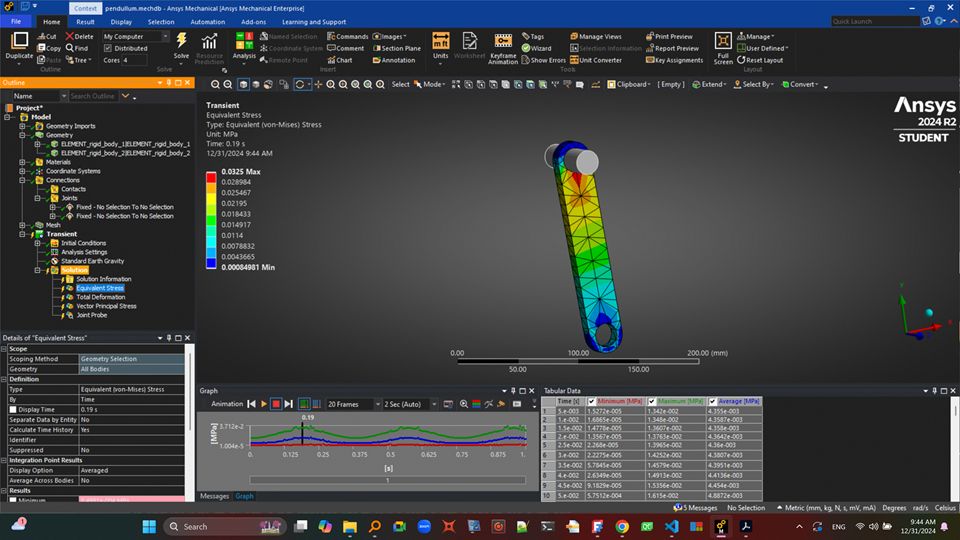

josegegas

SubscriberHere is an image. There are two joints: A fixed joint grounds the pin, and a revolute joint connects the pin and the pendulum (although, I do not know why; Ansys shows the second joint label as "fixed", but it is in fact a revolute). I set Earth's gravity pointing to global -Y. The pendulum is initially at the horizontal position, aligned with global X. The hinge axis is parallel to global Z, so the pendulum swings along the X-Y plane. When the pendulum swings, the revolute joint sees a reaction force. I have verified the value of this force by using another software to perform the same simulation and coparing the forces with those computed by Ansys. Reaction forces are correct. The bearing face is the cylindrical inner face of the pendulum hole, around which it pivots. I have removed the contacts Ansys adds bu default. I use solid tetrahedron elements for the mesh. I want to see the stresses in the pendulum resulting from the swinging. For this, Ansys should distribute the revoute joint force among the nodes that belong to the bearing face, and of course include the inertial forces resulting from the swinging in the fem simulation. But the thing is that the result stress distribution does not make sense. In the image above you can see von-Mises stress when the pendulum is near its vertical position (when the joint force is maximun and points to global +Y). You can see stress is concentrated at the bottom of the hole, which does not make sense: it must be at the top and in the sides instead. I believe this is because Ansys is distributing the joint force among the nodes in the bottom half of the hole instead of in the top, but Im not sure about this. So I would like to know how Ansys distributes rigid joint loads into the fem nodes, and If I have any control over how loads are distributed?

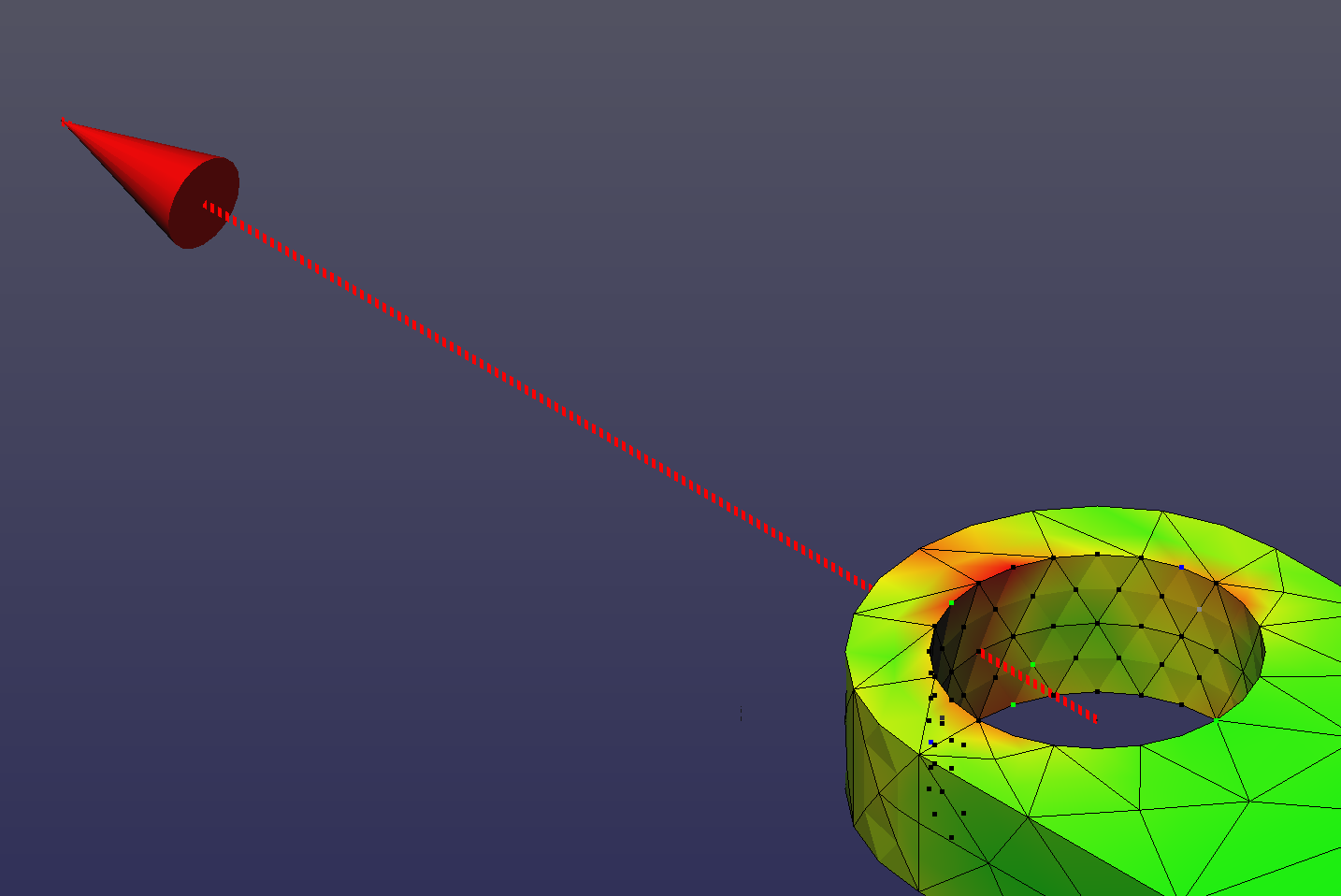

Here is a picture of what I am convinced is the correct stress distribution, simulated using another software.The red arrow is the joint force when the pendulum is vertical (half of its oscillation). The force computed by Ansys is correct: it is the same as the red force vector shown above and calculated with the other program. You can see that here the stress distribution is different than in Ansys results, and this stress distribution makes sense considering the force that the pin puts on the bearing face of the pendulum. In this image you can also see highlited the nodes among which the joint force (red vector) is distributed. These are only half of the nodes in the bearing face: in real world the pin would exert force only among these nodes. So given that Ansys is computing the correct joint force I think the problem is that it may not be distributing this force correctly among the nodes? I used exactly the same geometry for both simulations, same CAD, same density, same Young modulus and Poison's ratio, and verified mass and inertia matrix are good in both cases. Here is a video for reference. The first is Ansys and the second is the other software:

https://www.youtube.com/watch?v=8q90GKWCilQ

-

December 31, 2024 at 11:15 pm

peteroznewman

SubscriberA revolute joint idealizes a pin-hole connection between two bodies to make transient structural models solve much faster while delivering accurate forces. The trade-off for the fast solve is the local bearing stress is not accurate. There are several ways to obtain more accurate stress near the hole where the pin presses on one side of the hole.

A quick and simple way to improve the accuracy of the stress near the hole is to duplicate the transient structural model of system A to create system B, then replace B with a Static Structural analysis. Suppress the pin and joints, leaving only the link with two holes. Make the far hole a Fixed Support and apply the peak force over time from analysis A as a bearing load on the hole in analysis B, acting along the length of the link. A bearing load will create a good representation of the radial distribution of forces on the hole that add up to the total axial force. You will see the largest force at the top of the hole and the force will reduce to zero at +/- 90 degrees on either side. One advantage of this method is you can have a much more refined mesh because you only have to solve it once. The next method requires the solution to be completed for each time step, so a refined mesh takes much longer to solve.

A more accurate result for the stress near the hole is to delete the revolute joint and replace it with Frictional Contact between the pin and the hole. You might need additional axial contacts to prevent the link sliding off the pin, or the simulation might run without that. The trade-off for the more accurate stress is it will take much longer to solve. Frictional contact is slightly more accurate than the bearing load because the deformation of the hole can only be to match the cylindrical shape of the pin. The bearing load mentioned above does not limit the deformation to follow the surface of the pin, because there is no pin. If the wall thickness around the end of the hole was very thin, then that thin section could deform into a non-cylindrical shape under the varying radial bearing load.

-

January 1, 2025 at 1:25 am

josegegas

SubscriberI would not say stress is “not accurate” in the Ansys simulation results above. “Not accurate” impies at least some accuracy, but to me in this case the stress distribution is plain wrong. Ansys is showing minimum stress in the areas where in reality there would be maximum stress and vice-versa.

I also think a static structural analysis as descrived would not solve the issue. There will be some problems with this approach. First, a fixed support at one end would show stresses around the fixed nodes or even in other areas of the part, stresses that do not exists in reality. Second, the peak load at the other end may not be correctly distributed among the nodes in the bearing face. The load distribution may not be an accurate representation of how the pin would in reality apply load to the pendulum. This of course depends on the algorithm Ansys uses to distribute load using the “bearing load”. Is there a destription of this algorithm? Another issue with this is that the joint may also exert torque in addition to force. This torque woud have to be applied as a load to the bearing nodes, but how?

I think Ansys may have a better way to do this. Something like what other solvers call “inertia relief”. “Inertia relief” may also be a good description of how the results were obtained with the other software mentioned above. It basically computes the inertial forces for each solid element in the mesh, for each time-step of the MbD simulation, and then does the fem cancelling-out these inertial forces, by applying the “d’Alembert” force to each element. Taken from Wikipedia: “D’Alembert showed that one can transform an accelerating rigid body into an equivalent static system by adding the so-called “inertial force” and “inertial torque” or moment..”

How to do this in Ansys? How to apply “inertia relief”? I assumed Ansys would do this by default when doing transient analysis.

-

January 1, 2025 at 6:22 am

peteroznewman

SubscriberWhen you know how a revolute joint connection works, then you know to ignore the stress for a few diameters around the hole. Yes, it is plain wrong on the surface of the hole since it applies tension forces on the opposite side of the hole to the true solution, but this is fine if you know that and are willing to accept the trade-off to get accurate forces in a short amount of time. Remember that Saint-Venant’s principle tells us that the difference in stress in the link a large distance from the hole will become very small, even when the stress at the hole surface is just plain wrong.

In the simple Static Structural analysis I suggested, stress at the hole becomes fairly accurate, with the trade-off that the stress at the other end has become just plain wrong. But this is fine if you know that and ignore the stress at the other end. The bearing load applies forces in the radial direction only with a cosine fall off. Nodes have a force weighting of cosine(angle) between 0 and +/-90 degrees and the sum of the forces in the chosen direction equal the assigned value. As I mentioned, a bearing load is a good approximation for the load distribution of a close fitting pin in a hole and has the benefit of being quick and easy to use. I described the most accurate method of calculating stress in the hole and you are welcome to use that when needed but know that it will take more time. In many cases, the extra time is not warranted.

There are several methods to get accurate stress near the hole. A third method is to use Inertia Relief, which is available in Ansys. It will also use the Bearing Load in a Static Structural analysis so will give the same stress around the hole as the Static Structural analysis with the Bearing Load and the Fixed Support, but will not produce the wrong stress at the fixed support end. Click on Analysis Settings to turn Inertia Relief On. Watch this video for more information on Inertia Relief.

-

January 22, 2025 at 5:05 am

josegegas

SubscriberStill I was not able to get an acceptable simulation of such a simple mechansm. Can someone please help? I’m sure Ansys should be able to do this, I just do not know how to do it. I also do not understand why Ansys does not do a better job by default. For example, how is it possible that “it applies tension forces on the opposite side of the hole to the true solution”? Can someone please explain to me why Ansys would do this and how to tell it to apply loads on the correct side of the hole? Also, for such a simple model, I do not really care about solving time, trade-offs or optimization. I mean, the mesh is very coarse and I use a relatively long time-step: 1e-2 seconds time step for a total time of one second. Even a basic computer can solve this in a couple of minutes at most. I just need Ansys to apply the right loads on the right side of the hole surface, and to see the right stresses. Here is a more detailed explanation on how I achieved this simulation using open-source programs:

I created the CAD with FreeCAD. Then I performed the MBD simulation using MBDyn. Mesh was created using Gmsh. MBDyn outputs the accellerations of the mesh elements and the joint forces. From the accellerations of the mesh elements and the mass of each element, I compute the d-Alembert forces. From the mesh nodes and the joint forces I compute the loads to be appliead to the correct nodes in the hole surface (see the picture in my previous post, there is the force vector and the nodes among which load is distributed). Then I use Calculix to solve the FEM. In the Calculix file the d-Alembert forces are applied to the center of mass of all the solid (volume) elements. A 321 constraint is applied to the apropriate 3 nodes. And the joint force is distributed among the apropriate (half) nodes of the hole. The pendulum is therefore in static equilibrium all the time, and I can see a nice distribution of von-Mises stress right where they should be. Tensile and compressive stresses are also where one expects them to be. To achieve this with the open-sorce programs I had to manually create input files. When I started with Ansys I thought it would give me a correct simulation much easier, but I’m stuck. Any help will be much appreciated. How can I accrieve a simulation equivalent as the one descrived here, using Ansys?

Thanks in advance.

-

January 23, 2025 at 3:03 am

peteroznewman

SubscriberHere is a simple approach that uses Rigid Dyanamics to get the peak bearing force and Static Structural to get the stress around the bearing at that peak force using Inertia Relief.

-

January 24, 2025 at 2:22 pm

josegegas

SubscriberThank you, I appreciate it.

-

January 27, 2025 at 4:00 am

josegegas

SubscriberThanks again for the video, it was helpful, although in my Ansys student I cannot change the mesh element size. If I enter any value it puts it back to “automatic”. Is this a limitation of the student version?

Another question. If the gravity vector is not in the same plane as the pendulum oscillation (as in the previous example); then the revolute joint will see a reaction torque in addition to the joint reaction force. Also, the joint force will have a component along the axis of the hole, which in the previous canse was zero. The extreme of this would be to point gravity either to +Z or to -Z. In these cases all the joint force will be parallel to hole axis and the joint torque will be maximum (gravity acting on the pendulum center of mass times distance from center of mass to hole center). How can I apply these loads in the static structural simulation? In other words, I would need Ansys to give me the components of the force vector perpendicular and parallel to hole axis, and apply these components independently to the static structural simulation. The perpendicular component would use the same bering load while the parallel component would be a load distributed equally along all the mesh nodes in the hole. Then, the joint torque would also create a fem load (actually much higher than the load created by the force). How to apply the load from joint torque in the static simulation?

Thanks again.

-

January 27, 2025 at 4:55 pm

peteroznewman

SubscriberDid you import geometry into Ansys and mesh it in Ansys, or did you import the mesh from Gmsh using an External Model component in Workbench? If you import the mesh, you can't change the element size in Mechanical. If you import geometry and mesh it in Mechanical, you can change the element size. The Student license does not impose any limits on that.

For a link assembled on a vertically oriented shaft with a shoulder and shank that fits the hole, I would have both the shaft and link present in the model and apply gravity along the axis of the shaft. Frictional contact would be defined between the shank and the hole and another contact between the face of the shoulder and the face of the link. This is a nonlinear analysis and contact forces would build up on the top edge of the thin portion of the link and on the bottom edge on the opposite side of the hole to be in equilibrium with the moment the mass of the link at some distance from the shaft creates.

-

January 29, 2025 at 3:27 am

josegegas

SubscriberI meshed in Ansys. No mesh import.

Is there another way to do this in Ansys, using the force and torque from rigid dynamics? The reason is that I need to account for dynamic loads when there are both joint forces and joint torques. I also would like to automatically solve the fem for all the time steps of the rigid dynamics and visualize the stresses with the part within the assembly. When I first did a "transient structural" simulation and switched the pendulum from rigid to flexible, I expected Ansys to distribute joint force and torque to the epropriate fem nodes and solve for all time steps. It kind of did this. It solved for all time steps and there was stress, but the stress distribution showed that the joint force and torque were not apropriately distributed to the fem nodes. So in the end I think the key question is the same as in the begining of the post. In a transient structural simulation, when one of the bodies is turned to flexible, how does Ansys apply the joint loads to the fem nodes? And how does it account for inertial forces acting on the solid elements of the mesh? There should be some documentation about this right?

It would be great to clarify this. I have seen really many online tutorials where people do transient structural of more complex assemblies with several parts, then turn one of the parts into flexible, and simply solve and assume that stresses are correct. But I have not found any documentation on how Ansys does the fem part of the simulation. Many people use the default settings to do this, which may well lead to wrong stresses. How can we check how loads are applied to the mesh and, if necessary, change these settings? How does Ansys account for inertial forces?

Thanks in advance.

-

January 31, 2025 at 2:26 pm

peteroznewman

SubscriberI don't know how to apply the force and torque to the hole face that the revolute joint is scoped to in a way that creates realistic stress in the material around the hole. The way to get realistic stress in that material is to have a pin in the hole and use frictional contact as shown in this video which also shows why you can't expect realistic stress near the face used by a revolute joint. Any dynamic simulation is going to account for inertial forces.

-

February 6, 2025 at 9:43 pm

josegegas

SubscriberIs there a way to see how Ansys distributes fem loads? Or some documentation? Would be great to be able to see the loads in the animation. I made a video of something like what I would like to see:

-

February 7, 2025 at 4:37 am

peteroznewman

SubscriberIn the tilted pendulum with full contact analysis, the contact pressure can be plotted and that will animate as a contour plot on the surface mesh of the contact surface.

In the tilted pendulum with a Revolute Joint, the Total Force and Total Moment going through the joint can be animated as a vector arrow as shown in this short clip.

-

February 7, 2025 at 1:57 pm

josegegas

SubscriberIn Ansys the arrows have different color, blue green and red. What do the colors mean? Also, the double arrow represents torque right?

Thanks.

-

February 7, 2025 at 7:29 pm

peteroznewman

SubscriberYes, the double arrow is the moment.

You can plot a force component instead of the total force that I showed. Each component direction has a color: red=X, green=Y and blue=Z. When you see the arrow has all three colors, you know that is the total force vector. Same for moments.

-

April 11, 2025 at 1:23 pm

peteroznewman

SubscriberNew Discussion related to this discussion: https://innovationspace.ansys.com/forum/forums/topic/mbd-and-fem-of-a-simple-pendulum/

-

- You must be logged in to reply to this topic.

-

3487

-

1057

-

1051

-

945

-

917

© 2025 Copyright ANSYS, Inc. All rights reserved.