TAGGED: boundary-conditions, compressible-flow, fluent

-

-

February 17, 2022 at 2:18 am

Xbuddyin

SubscriberDear Friend,

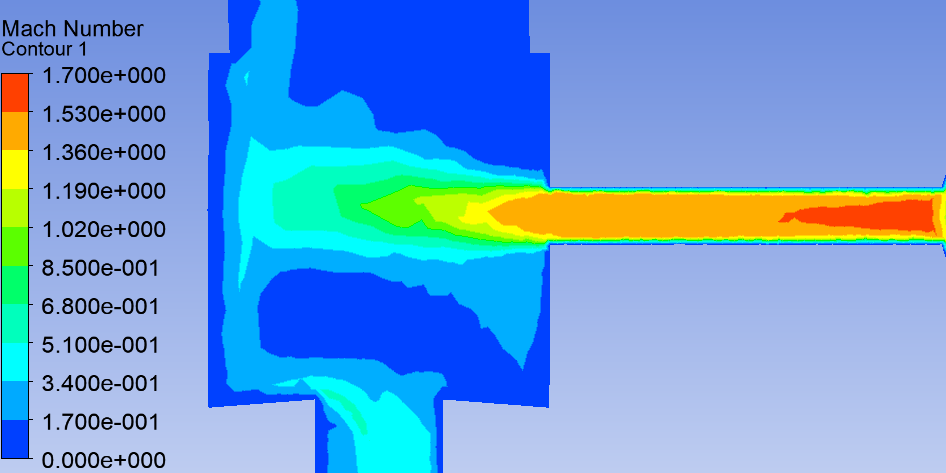

I was solving the airflow through the Tangle, in order to solve the problem, I choose the flowing fluid as "air" as compressible fluid. I am doing this as a control experiment. Pinlet (Gauge Pressure) :3 atm and Pout(Gauge Pressure) is 1atm. The temperature of the fluid is 300K (constant for inlet and outlet) .

Solver: Explicit, ROE and Grad: Node-based and Flow: Second upwind scheme.

Initialization: Hybrid

Steady-state problem:

Gravity: Y-axis :-9.81

Mach flow: Vel/Sqrt(1.4*287*Totat Temp) and Courant Number:1 and

I am not sure, why I am getting such a high temperature and Impossible Mach number through the T-channel. This result in the CFD post doesn't make any sense. I am not sure where I am making mistakes in defining the BC or meshing issue., solver, or anything else. Do I need to put any operating pressure, if I am just simulating for the flow at atmospheric conditions? any suggestion will be helpful.

Error shown by TUI for every iteration: Solver: " time step reduced in 707 cells due to excessive temperature change

temperature limited to 1.000000e+00 in 729 cells on zone 3

temperature limited to 5.000000e+03 in 961 cells on zone 3

200 1.8851e+00 5.7939e-01 8.1209e-01 7.1154e-01 8.3318e-01 0:00:00 0 "

February 17, 2022 at 1:18 pmRob

Forum ModeratorThe warning means you're hitting the solver temperature limits so the results are going to be somewhere between misleading and rubbish when you come to plot. With pressure in and out the mass flow becomes part of the solution, and that can require carefully set initial conditions.

Use inflation and refine the mesh where you think the pressure gradients are going to be: ie do you expect jetting from the inlet pipe?

Finally, try the Pressure Based Coupled Solver. We only tend to use Density based for complex high Mach Number flows and very tightly coupled systems (combustion being one example).

February 17, 2022 at 5:10 pmXbuddyin

Subscriber

Thanks, Rob for your answer Thanks, I am getting the logical answer when I use the Pressure based solver for the air, I still got some higher Mach number in the pipe inlet, any suggestion, it may be due to the meshing. But the manual clearly differentiates the use of a pressure-based solver for the incompressible fluid, the thing, here is the thing that during the project extension, I would like to use the PR other gas EOS in the future, I am not sure if I can still use the Pressure Based solver. Any comment on that.

When I tried to use the density of the air to be computed using the ideal gas, using the pressure-based solver.

Solver Error : "

Error: Error occurred during handling message in WorkBench: An error occurred in FLUENT during the execution of an internal command. An error occurred in FLUENT during the execution of an internal command

Error Object: #fiter continuity x-velocity y-velocity z-velocity energy time/iter

1 1.0000e+00 3.1098e-02 2.7651e-02 2.8384e-02 5.7729e-02 0:00:16 249

2 1.0000e+00 3.0083e-01 4.4546e-02 4.1878e-02 5.0551e-03 0:00:12 248

# Divergence detected in AMG for temperature: protective actions enabled!

# Divergence detected in AMG for temperature, temporarily solve with BCGSTAB!

3 1.0000e+00 1.6083e-01 3.3575e-02 3.2518e-02 1.1364e-02 0:00:10 247"

Yes, I think there will be Jetting from the inlet pipe the passage is very small. I think the jetting velocity will be increased due to the large pressure gradient up to 1500 psi. There are obstacles in the big cross-sectional area but I am initially doing the flow analysis without it in order to understand to simplify the problem and air as sample fluid.

February 18, 2022 at 9:44 amRob

Forum ModeratorThe blockage might help the stability depending on what that does to the overall pressure loss. Equally it could lead to all sorts of interesting flow separation effects so cell count and meshing are going to be important. You do need to refine the mesh into the chamber as that's where all the interesting things are going to happen.

Pressure based (Coupled Solver) is good to Mach 2-3 and I'm told pretty good for higher Mach Numbers. I very rarely use the density based solver, in fact I can't remember last time I did other than the check a tutorial for a colleague. For density based you'll need to be more careful with the mesh and look at the Courant Number settings very carefully. PBCS may need the pseudo time step reducing to 0.1-0.2 or the courant number to around 25-50 (depending on the options you pick) but should otherwise behave. As you're using Fluent I'd post process in Fluent too, it's quicker.

February 18, 2022 at 7:25 pmXbuddyin

SubscriberThanks for your answer.

Viewing 4 reply threads- The topic ‘high Temperature shoot up and high mach flow.’ is closed to new replies.

Ansys Innovation SpaceTrending discussionsTop Contributors-

3467

-

1057

-

1051

-

918

-

896

Top Rated Tags© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-