TAGGED: convergence, mechanical, mesh, mesh-convergence, sensitivity-anlysis

-

-

May 25, 2021 at 11:32 am

mattobrasil

SubscriberHi everyone,

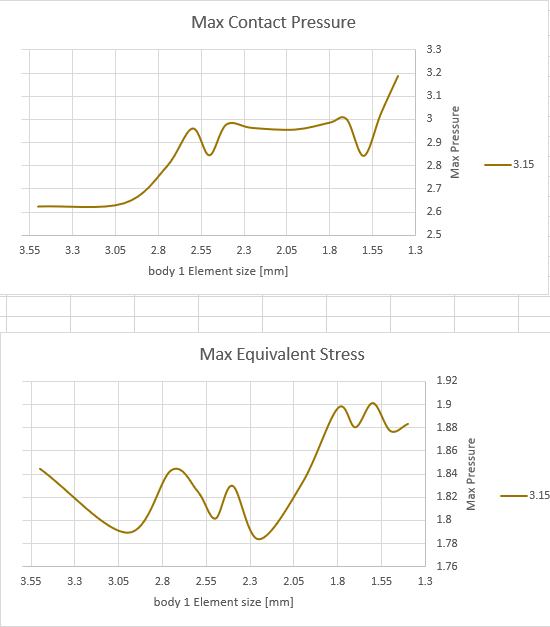

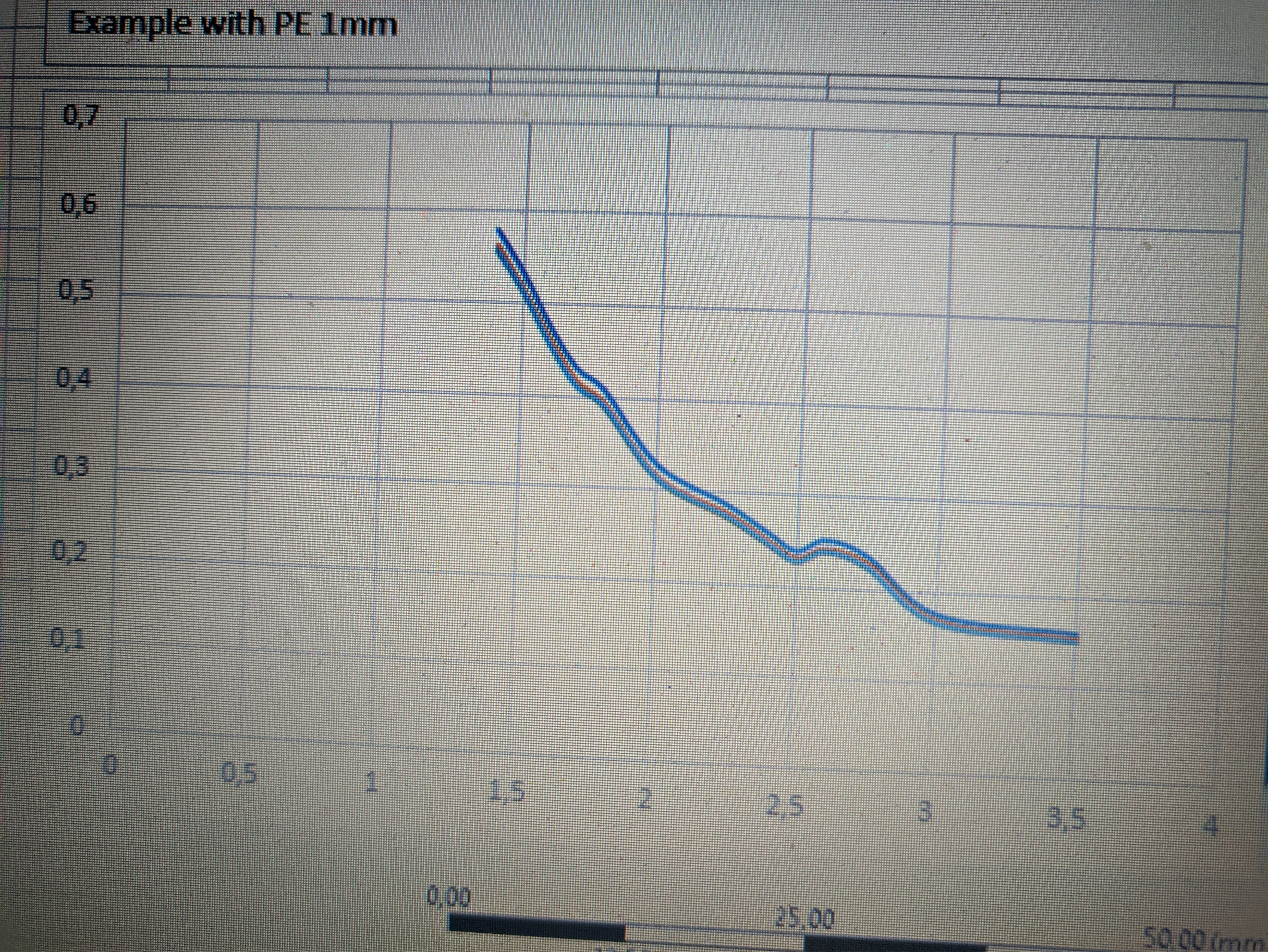

I am trying to do a mesh sensitivity analysis in which I have to find a good mesh size for two bodies in contact with each other. I am applying a simple force to have a contact between (one body is fixed, I apply 1000N to the other one) them and extracting the maximum contact pressure and the maximum Equivalent Stress. Unfortunately I don't have a proper convergence, instead I have strange results. What can I do to have a convergence?

May 25, 2021 at 12:48 pmAkshay Maniyar

Ansys Employee

I am not sure exactly why you are getting such plots. Can you share some more details of your model? (geometry, materials used, contacts definition etc. )

regards amaniyar

May 25, 2021 at 12:58 pmmattobrasil

SubscriberThank you for your answer.

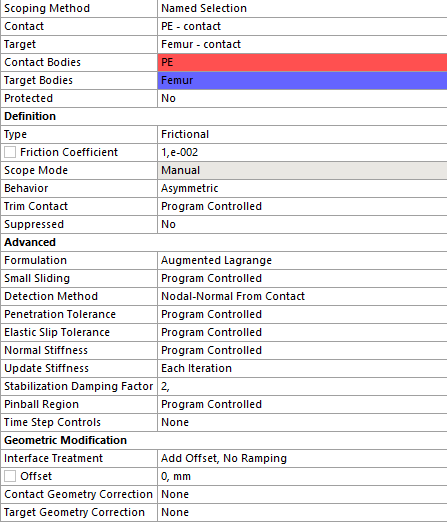

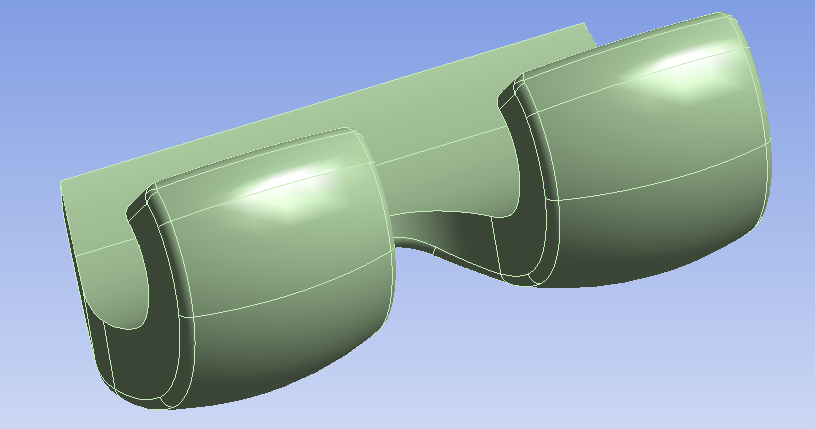

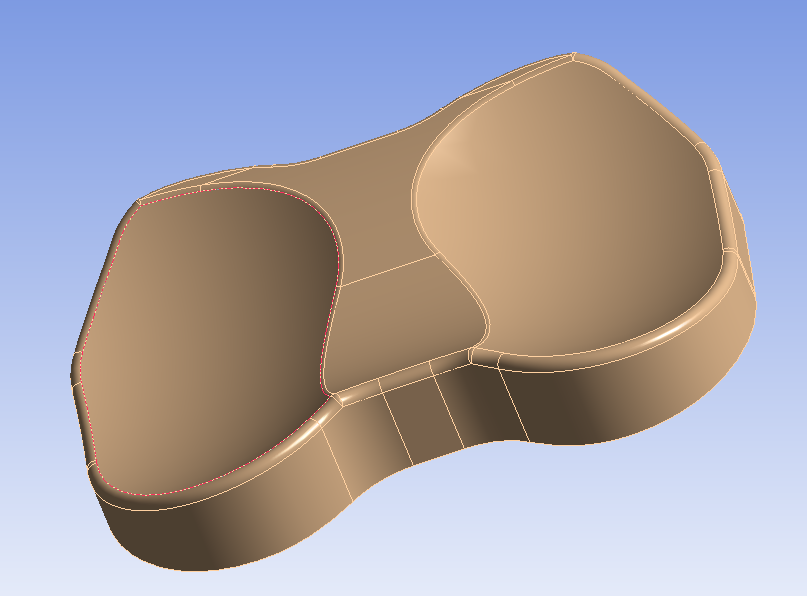

Here are all the information. The bottom object (brown one) is in a generic Polyethilene (from Ansys db) and the upper body in Structural Steel. I have applied a static load ramped of 1000N from the bottom surface of the lower body and it gets in contact with the upper body's surface (which is fixed to the ground).

Here are all the information. The bottom object (brown one) is in a generic Polyethilene (from Ansys db) and the upper body in Structural Steel. I have applied a static load ramped of 1000N from the bottom surface of the lower body and it gets in contact with the upper body's surface (which is fixed to the ground).

May 25, 2021 at 1:40 pmAkshay Maniyar

Ansys Employee

Can you explain what you want to simulate exactly? Also, why you have used the stabilization damping factor as 2?

When you ran your model, is it converging properly or is there any issue? As your frictional coefficient is very less, it might give some problem while converging.

regards amaniyar

May 25, 2021 at 1:45 pmmattobrasil

SubscriberI should simulate a joint and evaluating the reaction moments and contact pressure on the lower body. Damping factor was added for the dynamic simulation and I forgot to put it back to 0. The contact for the plot I sent you is actually Frictionless, but I guess it shouldn't have greatg influence anyway. I also have no problem at all in converging, only the results put together seem oddMay 25, 2021 at 2:05 pmAkshay Maniyar

Ansys EmployeeHi @mattobrasil Have you tried with 0 damping factor or 2?

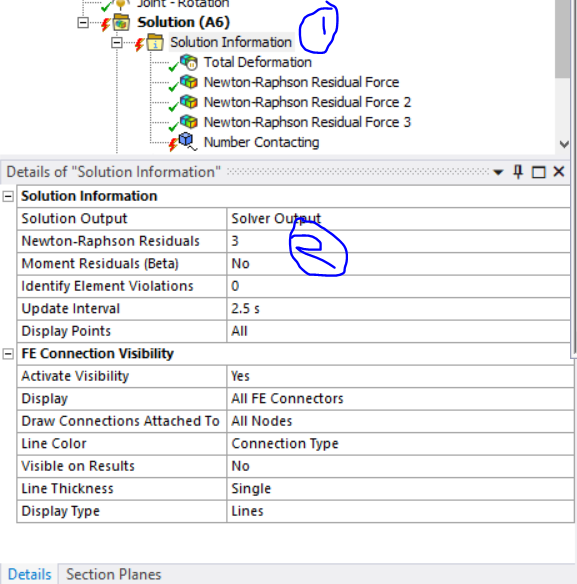

Can you check the contact status, Newton-Raphson residuals ?because mesh can affect how many contact elements are in each status, which can affect the final result.

You can also manually do mesh sensitivity study by changing the element size.

regards amaniyar

May 25, 2021 at 2:14 pmmattobrasil

SubscriberI tried with a damping factor of 2, now I am trying again with a damping factor of 0. Anyway I have parametrized the element size and created a series of design points in which I decrease both mesh sizes. How do I check the residuals?

May 25, 2021 at 2:24 pmMay 25, 2021 at 2:33 pmmattobrasil

SubscriberThank you very much, I'll try this and let you know about the results!

May 26, 2021 at 9:46 ammattobrasil

SubscriberGood morning I have tried as you said but the residuals don't show since the simulation always converges. I also tried without the damping factor, it didn't seem to have a huge effect anyway. Do you have any other suggestion?

May 26, 2021 at 1:56 pmAkshay Maniyar

Ansys Employee

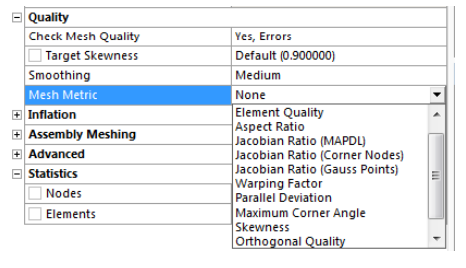

I am not sure with your issue. But as there is no issue with converging. So issue can be with mesh. Please check the mesh quality and then you can try mesh sensitivity study manually.

regards amaniyar

May 26, 2021 at 2:02 pmmattobrasil

SubscriberThank you for the suggestion. How can I check the mesh quality in Amsys mechanical?

May 26, 2021 at 2:49 pmMay 27, 2021 at 5:38 amAkshay Maniyar

Ansys Employee

When you are checking results, please check average value instead of maximum value as there can be singularities in the model.

regards amaniyar

May 27, 2021 at 9:18 amJune 20, 2021 at 11:54 pmJerrin

SubscriberHi @mattobrasil,

I actually faced the same problem. My values kept increasing when the mesh element sizes reduced. I assume this could be because of the irregular shaped body you are using. As Stress is equal to Force over Area, as the element size changes over the irregular shaped body, the element area also reduces which causes an increase in stress. If you have used ANSYS for your previous meshing, try the adaptive meshing technique which will try rectifying this.

Do let me know if this works out.

CheersJune 21, 2021 at 11:36 ammattobrasil

SubscriberThank you for the answer! I'd loke to know how can I use this function. Thank you very much in advance!

Viewing 16 reply threads- The topic ‘Help with mesh sensitivity analysis’ is closed to new replies.

Innovation SpaceTrending discussionsTop Contributors-

4728

-

1565

-

1386

-

1242

-

1021

Top Rated Tags© 2026 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.

-

The Ansys Learning Forum is a public forum. You are prohibited from providing (i) information that is confidential to You, your employer, or any third party, (ii) Personal Data or individually identifiable health information, (iii) any information that is U.S. Government Classified, Controlled Unclassified Information, International Traffic in Arms Regulators (ITAR) or Export Administration Regulators (EAR) controlled or otherwise have been determined by the United States Government or by a foreign government to require protection against unauthorized disclosure for reasons of national security, or (iv) topics or information restricted by the People's Republic of China data protection and privacy laws.