-

-

October 3, 2025 at 7:14 pm

shrihari_sampathkumar

SubscriberHello,

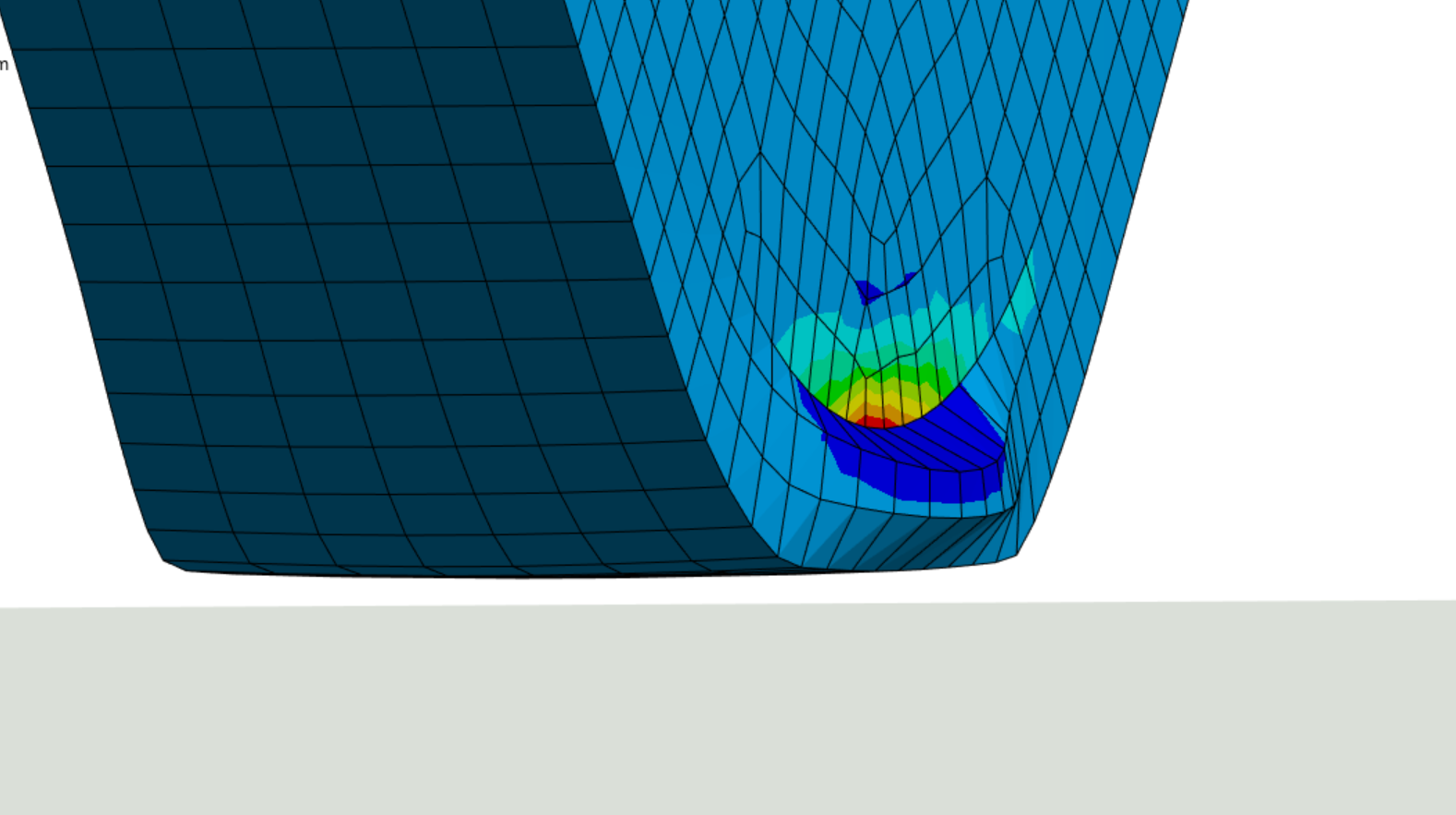

I have a drop-impact simulation of a Glass+Plastic (polycarbonate) assembly. I'm get results that look like the Polycarbonate is undergoing plastic deformation.

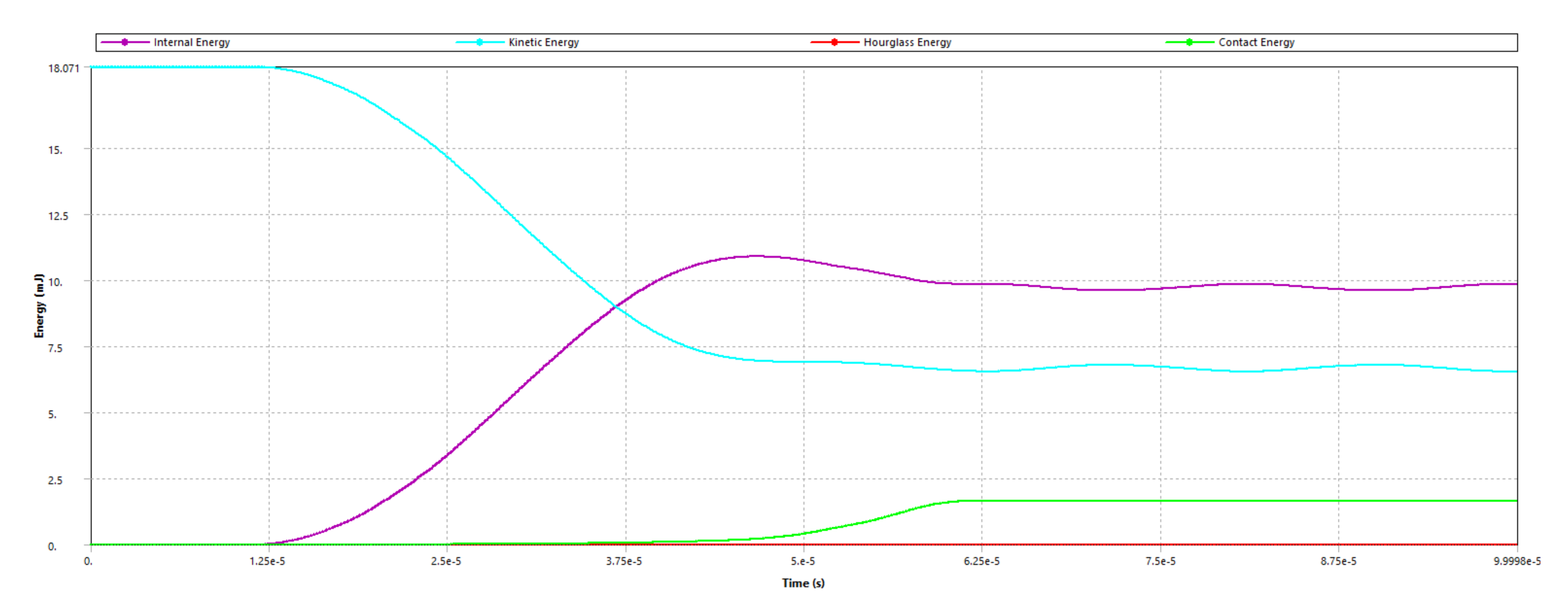

However, I have limited experience validating plastic deformation in LS-DYNA and would like some help on this. I'm especially worried if i've artificially introduced some non-physical plastic deformation in my attempts to eliminate Hourglass energy.

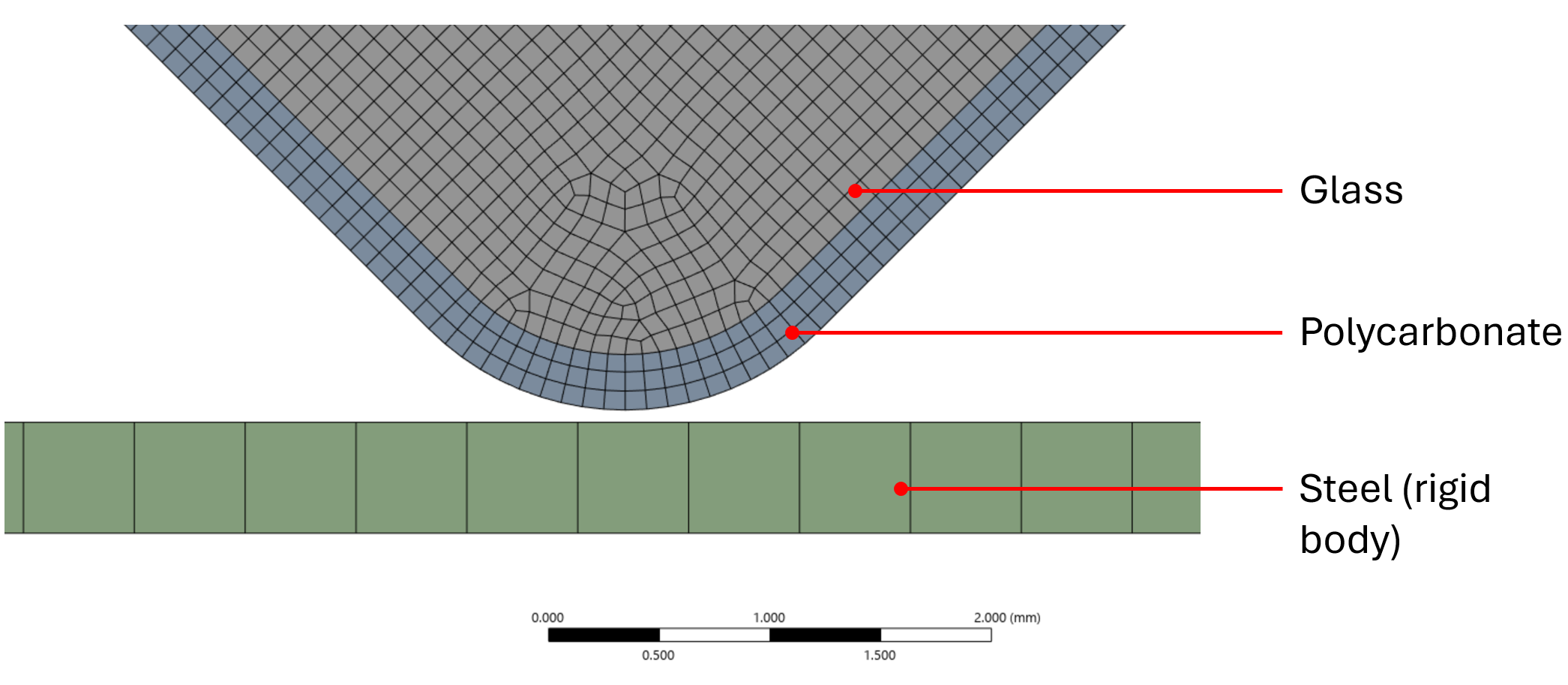

Setup:

- Materials: Glass - Proprietary (substrate) , Plastic, PC High viscosity - Ansys default library (around the glass perimeter) , Steel - Default library(rigid body- shell)

- Contacts:

- Glass <-> PC : Shared topology

- PC <-> Plate : Frictional

- Behavior: Asymmetric

- Formulation: Pure Penalty (Automatic_nodes_to_surface)

- Viscous damping coefficient: 0.1

- Contact / Target Penalty Scale Factors: 10

- Soft Constraint Formulations: Segment Based

- Soft constraint Scale Factor: 1

- Depth: 2

- Mesh: Hex8 (for glass, PC), and Quad4 (plate)

- Hourglass controls:

- PC: ID 7 (Belytschko-Bindeman Linear Total Strain), coefficient = 1

- Element Controls:

- PC: Fully Integrated S/R Solid

- Analysis setting:

- Global Hourglass control: ID 5 (Exact Volume Flanagam-Belytschko Stiffness Form), coefficient = 0.1

Points to note / Concerns:

- High distortion of the PC (not sure how I can check this is actually physical/ potential mesh issue)

- The contact energy increases and stays high (I think this is ok since there's sliding at the frictional interface)

- Internal energy stays high after impact (again, I think this is physical since there's work done on the PC layer)

-

Viewing 0 reply threads

- You must be logged in to reply to this topic.

Ansys Innovation Space

Trending discussions

Top Contributors

-

3977

-

1461

-

1272

-

1124

-

1021

Top Rated Tags

© 2025 Copyright ANSYS, Inc. All rights reserved.

Ansys does not support the usage of unauthorized Ansys software. Please visit www.ansys.com to obtain an official distribution.