-

-

May 14, 2025 at 6:49 am

s.breyer

SubscriberHi,

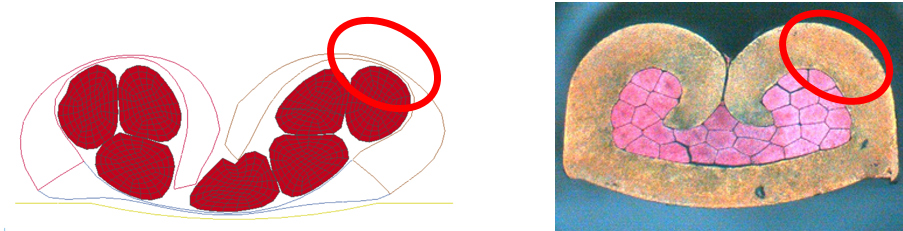

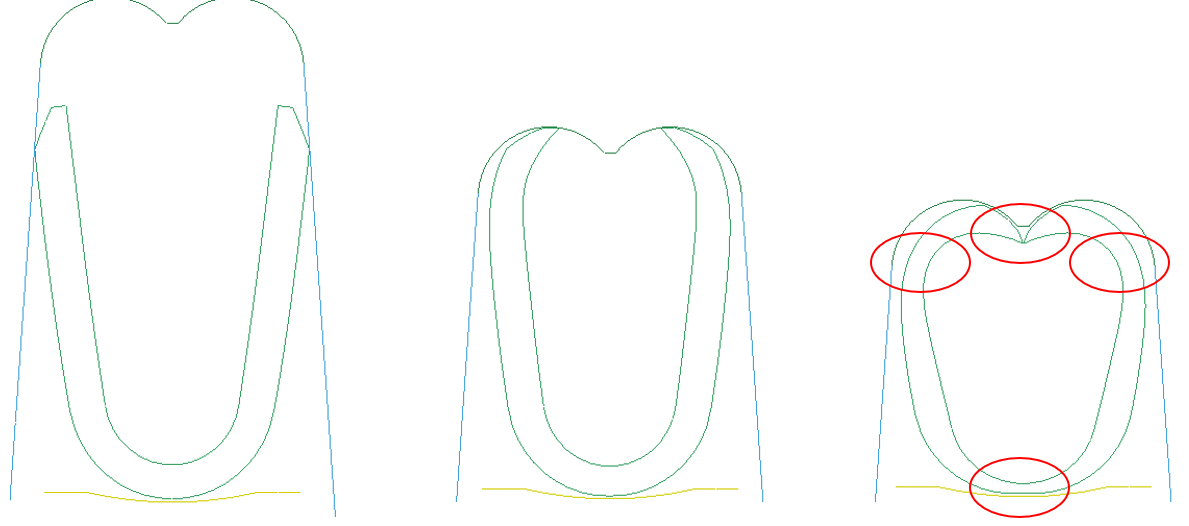

I tried different material models for a crimp simulation but as you can see in the picture, the crimp is too squashed on one side. It should look like the one on the right in the picture.

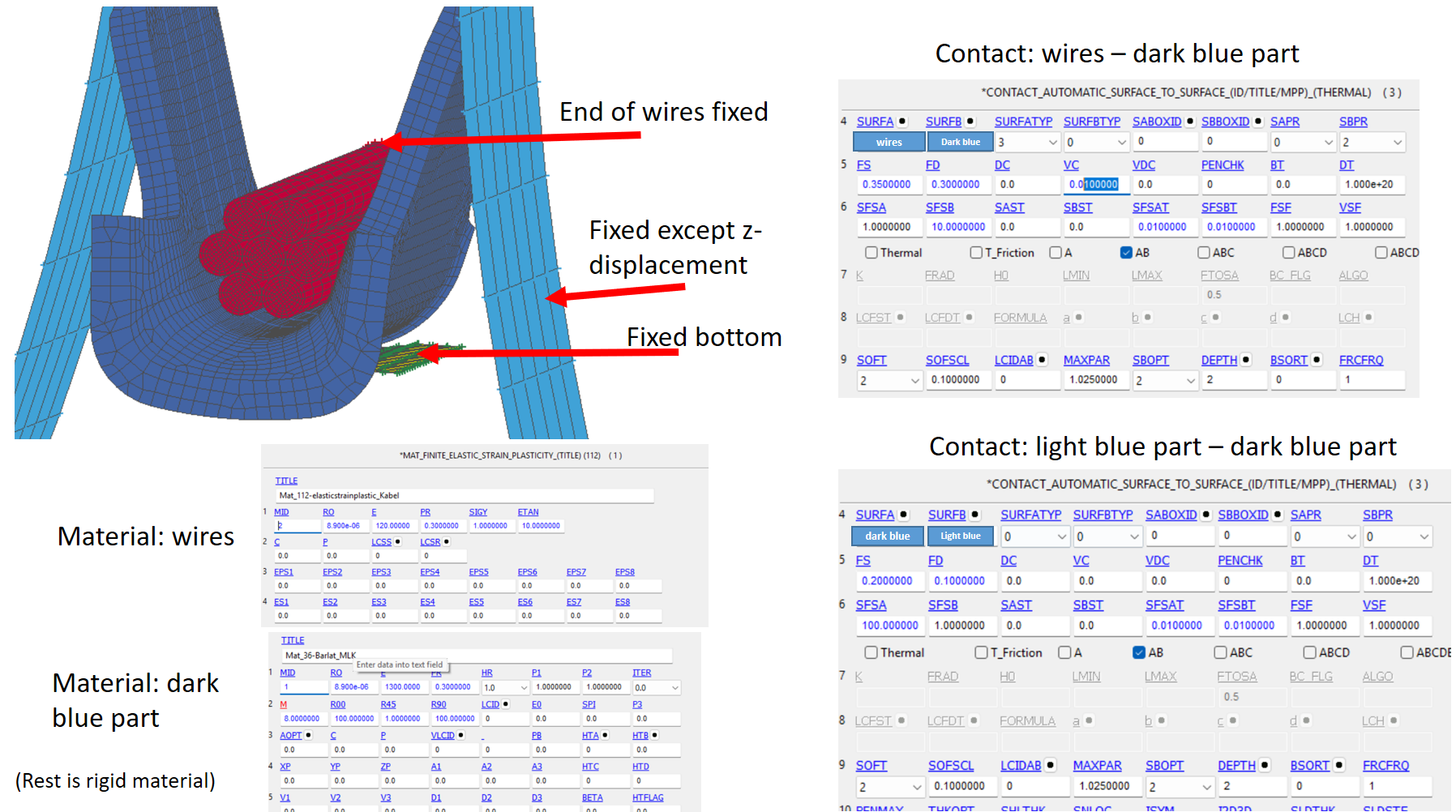

Material models I tried (also with extra high Young's Modulus):

Mat01_Elastic, Mat03_PlasticKinematic, Mat24_PiecewiseLinearPlasticity, Mat36_Barlat, Mat112_FiniteElasticStrainPlasticity.They all give the same problem result.

-

May 14, 2025 at 6:40 pm

-

May 16, 2025 at 8:41 am

-

May 23, 2025 at 9:04 am

Raman Babu

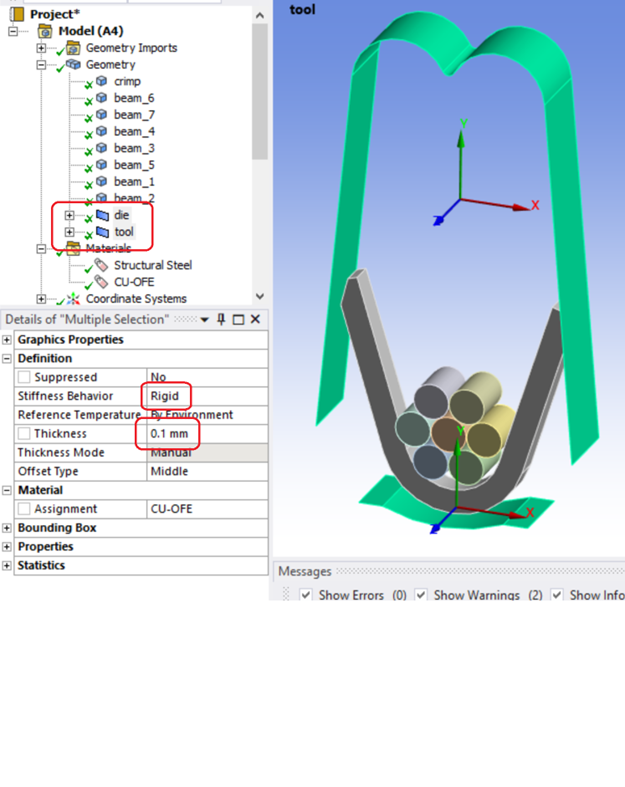

Ansys EmployeePlease specify the constraint to *MAT_rigid through CMO =1 for rigid parts

Also, you can specify the Die and tool as rigid.

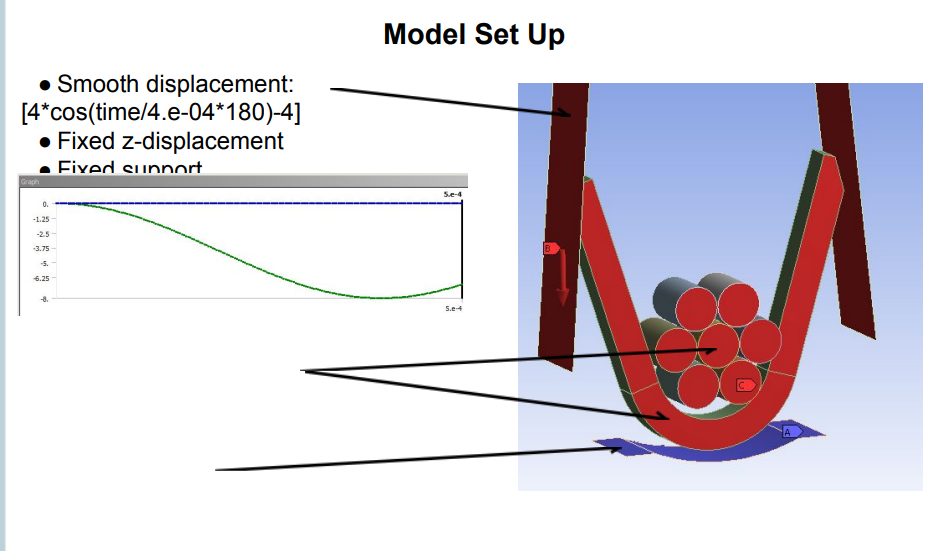

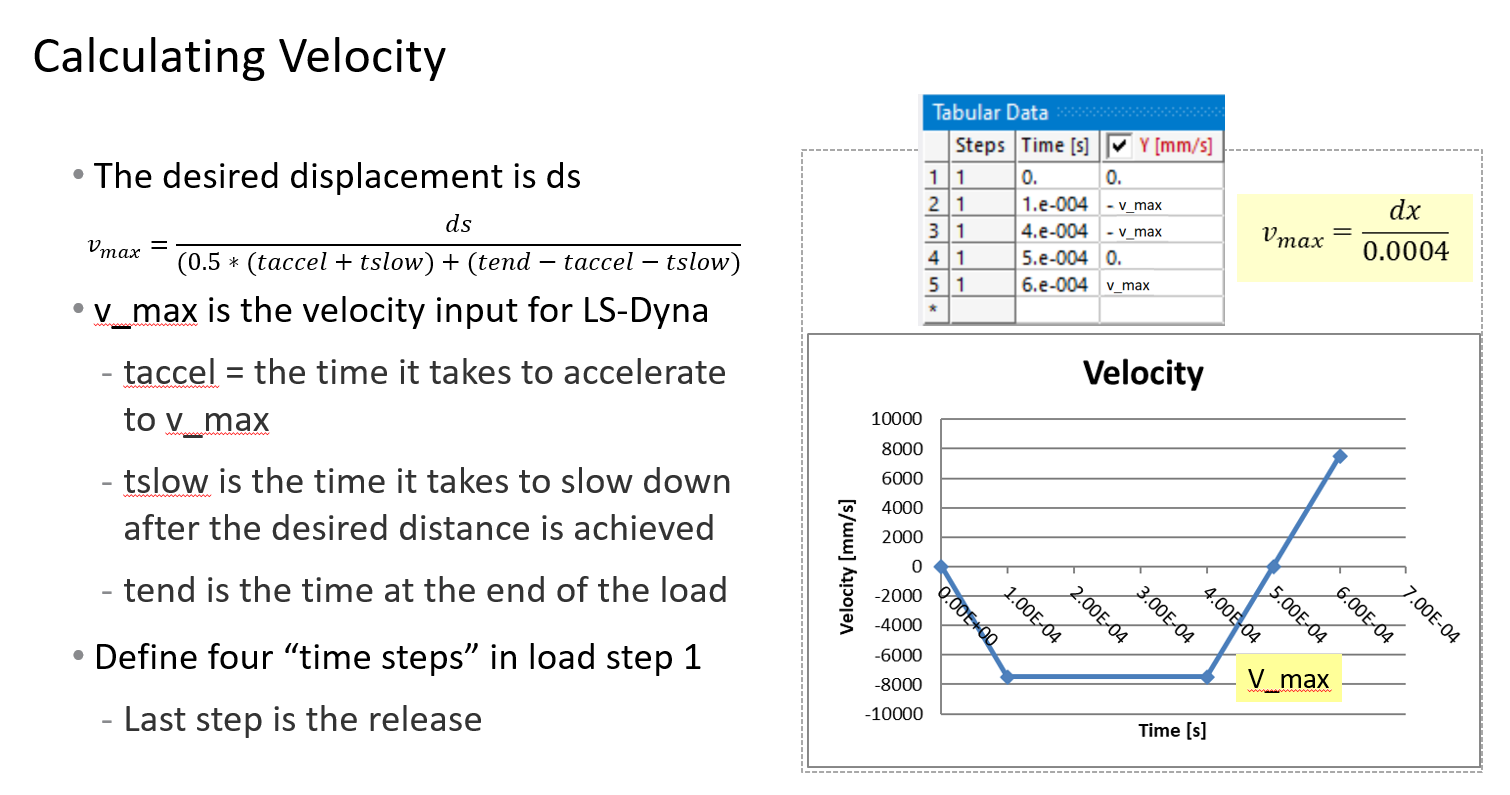

Loading condition:

Other conditions:

•Apply velocity to a tool body•Displacement on the wires in the axial direction•Rigid Body Constraint-Anvil is fixed-The tool is free in velocity direction but fixed otherwisePlease try to readjust your setup and let me know your findings.

-

May 26, 2025 at 8:39 am

s.breyer

SubscriberHi,

just to clarify, i am using the free student version

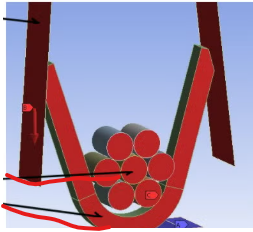

rigid body parts (thickness 0.05):

- light blue part (110111 – only move in Z)

- bottom die (111111 – no move)

wires – solid part (see material in the picture above):

- end of wires (111111 – the long end is fixed)

movement (only light blue part is moving to form the crimp)

i used z-displacement, so no “velocity”, just prescribed_motion_rigid DOF=3 & VAD=2

-

June 4, 2025 at 6:27 am

-

June 11, 2025 at 6:43 am

-

June 11, 2025 at 11:43 am

s.breyer

SubscriberHi,

i did and nothing changes at all. I still have problems with the volume constancy of the metal. The piece of metal should only roll inwards, but not be deformed in width.

-

- You must be logged in to reply to this topic.

-

3597

-

1243

-

1092

-

1068

-

953

© 2025 Copyright ANSYS, Inc. All rights reserved.